K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

64 MB

Estimated Shipping Size

Dimensions: 4.0" x 0.8" x 1.0"

(10.2 cm x 1.9 cm x 2.5 cm)

Weight: 0 lbs 1.1 oz (0.0kg )

Tariff Code: 8523510000

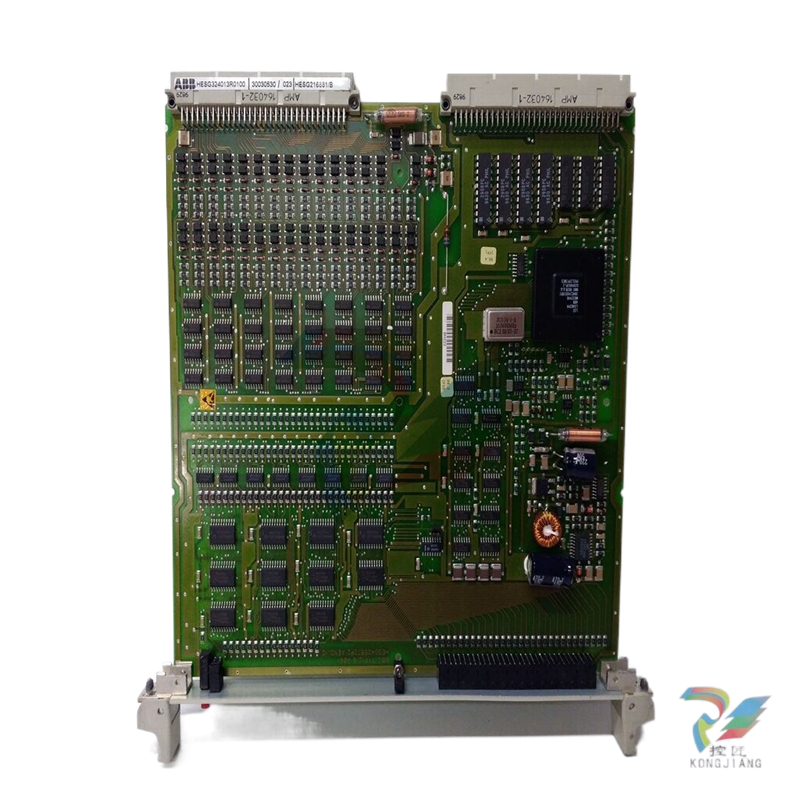

ABB GJR5252600R0201 07 MC 90 C1 Memory Module

Product Overview

Model identification: ABB GJR5252600R0201 07 MC 90 C1 is a memory module. Individual parts of the model number may represent a specific product family, version, feature, or other identifying information. For example, ‘GJR5252600R’ may be the product line number to which the memory module belongs, ‘0201’ may be a version number or specific configuration code, ‘07 MC 90 C1 ‘ may be used to further distinguish the type of memory module, its application scenario, etc. within ABB's product portfolio.

Functionality: As a memory module, it is mainly used to store data and programs, and is a key component for data storage and reading in the whole system, playing an important role in industrial automation systems or other related equipment, similar to a memory stick in a computer, but may be optimised for industrial environments and specific equipment.

Performance Characteristics

Storage Capacity and Type

Capacity specification: Although the exact storage capacity is not explicitly mentioned, it is presumed from the model number that it should have a certain storage capacity that can meet the data storage needs of the device to which it is applied. This capacity may be designed according to the common application scenarios and data processing requirements of the target device, e.g. it may be used to store control programmes, configuration parameters, historical data records, etc.

Storage type (speculative): Flash Memory or other non-volatile storage technology may be used. The advantage of non-volatile storage is that data is not lost when the device is powered down, which is important for devices in industrial environments where power supply may be interrupted for various reasons (e.g., power outages, maintenance, etc.).

Data reading and writing performance

Read and write speed: In order to adapt to the rapid data processing and response needs of industrial control systems, the memory module should have a faster data read and write speed. For example, in real-time monitoring and control of industrial scenarios, when the system needs to quickly read the control programme instructions or store new sensor data, the memory module can respond quickly to ensure that the system is real-time and efficient. Its read and write speed may be affected by the type of memory chip, interface protocols and internal circuit design and other factors.

Data transmission stability: In industrial environments, there are various electromagnetic interferences and signal fluctuations, so the data transmission of this memory module must be highly stable. It may adopt some anti-interference technologies, such as electromagnetic shielding, data checking and error correction, and other mechanisms to ensure the accuracy and integrity of the data in the reading and writing process.

Reliability and Durability

Working life: Considering the long-term operational requirements of industrial equipment, the memory module should have a long working life. It should be able to withstand frequent data read/write operations and long periods of energised use, and be able to maintain stable performance throughout its service life. For example, by using high-quality memory chips and reasonable circuit design, the wear and tear and aging of the chips can be reduced to extend the service life of the module.

Environmental Adaptability: Industrial environmental conditions are usually harsh, including temperature changes, humidity changes, dust, vibration, and other factors. The memory module may have good environmental adaptability, can work normally in a wide temperature range (such as - 20 ℃ - 70 ℃), and has a certain resistance to humidity, dust and vibration, etc., to ensure that the data can be stored reliably in a variety of industrial field conditions.

Application Areas

Industrial automation control systems

PLC (Programmable Logic Controller) System: As an important component for storing control programs and data in PLC systems, PLCs are used to control the automated operation of a variety of industrial equipment, such as motors, valves, conveyor belts, and other equipment in automated production lines. The memory module can store complex control logic programs to ensure that the PLC can accurately and quickly perform control tasks, and can save the operating parameters and status information of the equipment to facilitate fault diagnosis and system maintenance.

DCS (Distributed Control System): In DCS system, it is used to store the data and programs of distributed control units.DCS is widely used in chemical, electric power, petroleum and other process control fields, and this memory module can help to realise the decentralised control and centralised management of the whole production process. For example, in the chemical production process, it can store the control procedures and parameters of each reactor, pipeline, pump and other equipment to ensure the stable operation of the entire chemical production process.

Industrial computer and monitoring system

Industrial computer: as a memory expansion or special storage device in the industrial computer. Industrial computers are used to run industrial control software, data acquisition and analysis software, etc. The memory module can provide additional storage capacity for storing large software programs, databases and long-time data records. For example, in the monitoring system of an intelligent factory, the industrial computer needs to store a large amount of equipment operation data and image information, and the memory module can meet this storage demand.

Human-machine interface (HMI) devices: Store screen configuration data, historical data, etc. in HMI devices, which are used for interaction between operators and industrial equipment, displaying equipment status and receiving operator commands through a graphical interface. The memory module ensures that the HMI device can quickly load and switch the display screen, and can save operation records and alarm information, etc., for operators to view and analyse.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923