K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

2 MB

Estimated Shipping Size

Dimensions: 1.5" x 1.0" x 1.8"

(3.8 cm x 2.5 cm x 4.4 cm)

Weight: 0 lbs 1.1 oz (0.0kg )

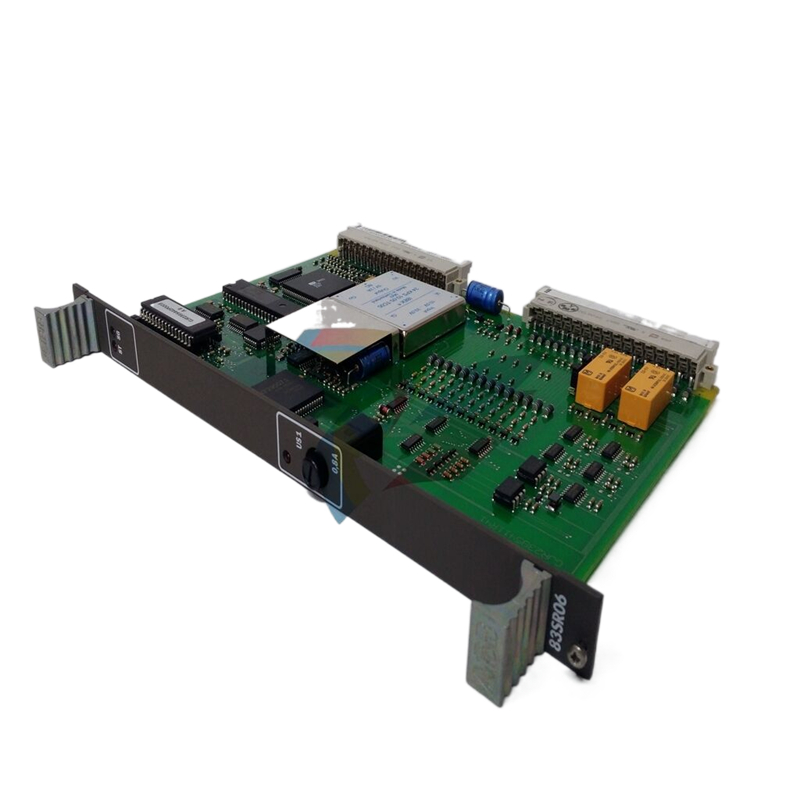

ABB GJR5252600R0101 07 MC 90 Memory Module

Basic Product Information

Model details: ABB GJR5252600R0101 07 MC 90 is a memory module. The ‘GJR5252600R’ part may be a product series or family identifier, the ‘0101’ may be a version number, configuration variant or other distinguishing number, and the ‘07 MC 90 ‘ may be used to classify and identify the memory module within the wider ABB product catalogue.

Functional position: The memory module is used throughout the industrial control system or associated equipment to store data and programme code. It acts as a data warehouse, providing the necessary information storage and reading functions for the proper functioning of the equipment and ensuring that the system works according to predefined rules and instructions.

Performance Characteristics

Storage Capacity and Performance

Storage capacity assumption: Although the storage capacity is not explicitly given, it is assumed from its position in the ABB product family and the specifications of similar products that it should have sufficient capacity to meet the common needs of industrial applications. This may include storing control programmes, device configuration parameters, historical data records, etc. The size of the storage capacity will vary depending on the specific application scenario and may range from a few megabytes (MB) to several gigabytes (GB).

Data read/write speed: In order to adapt to the rapid data processing and device response requirements in industrial environments, the memory module should have a high data read/write speed. In industrial automation systems, such as real-time monitoring and control scenarios, the need to quickly read control programme commands or store newly collected sensor data in a timely manner requires the memory module to be able to efficiently complete data read and write operations. The read/write speed may be affected by a combination of factors such as memory chip technology, internal circuit design and interface protocols.

Reliability and Stability

Hardware Reliability Measures: Manufactured with high quality memory chips and electronic components that undergo a rigorous screening and quality testing process. For example, the memory chips may have high resistance to wear and fatigue to cope with long hours of operation and frequent data reading and writing in industrial equipment. Also, the circuit board may be designed with electromagnetic compatibility (EMC) in mind, with effective shielding measures to minimise the impact of external electromagnetic interference on data storage.

Data protection mechanism: It may be equipped with data verification and error correction functions. In industrial environments, due to the presence of various interference factors, errors may occur during data storage and transmission. Through the data checking and error correction code technology, the memory module can automatically detect and correct some common data errors to ensure the integrity and accuracy of the stored data. In addition, in order to prevent data loss due to unexpected power outages, non-volatile storage technologies such as Flash Memory or storage solutions with backup power may be used.

Compatibility and integration

Compatibility with ABB equipment: The memory module is designed to have good compatibility with other ABB industrial control equipment and systems. It can be easily integrated with ABB's controllers, Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS) and other devices. For example, it matches ABB's mainstream products in terms of interface types, communication protocols and electrical characteristics, allowing users to seamlessly add it to existing ABB automation systems and extend the system's storage capabilities.

Universal compatibility (possible): In addition to being compatible with ABB equipment, it may also support some common industry-standard interfaces and protocols to some extent, which allows it to be integrated with other brands of industrial equipment in some cases. However, it is primarily designed and optimised around the ABB product ecosystem.

Areas of application

Industrial automation control systems

PLC Application Scenario: As a key component for storing control programs and data in Programmable Logic Controller (PLC) systems, PLCs are widely used in a variety of industrial automation lines in industries such as automotive manufacturing, machining, and food and beverage production. The memory module can store complex control logic programmes, enabling the PLC to accurately control the operation of motors, valves, conveyor belts and other equipment according to different production processes and process requirements. At the same time, it can also record the operating status and fault information of the equipment, which is convenient for maintenance personnel to carry out fault diagnosis and system maintenance.

Role in DCS system: In distributed control system (DCS), it is used to store the data and procedures of each distributed control unit.DCS is often used in chemical, petroleum, electric power and other process control fields to carry out decentralised control and centralised management of the whole production process. For example, in the chemical production process, the memory module can store the temperature control program of the reactor, pipeline flow monitoring data and configuration parameters of various chemical equipment, etc., to ensure the safe, stable and efficient operation of the chemical production process.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923