K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

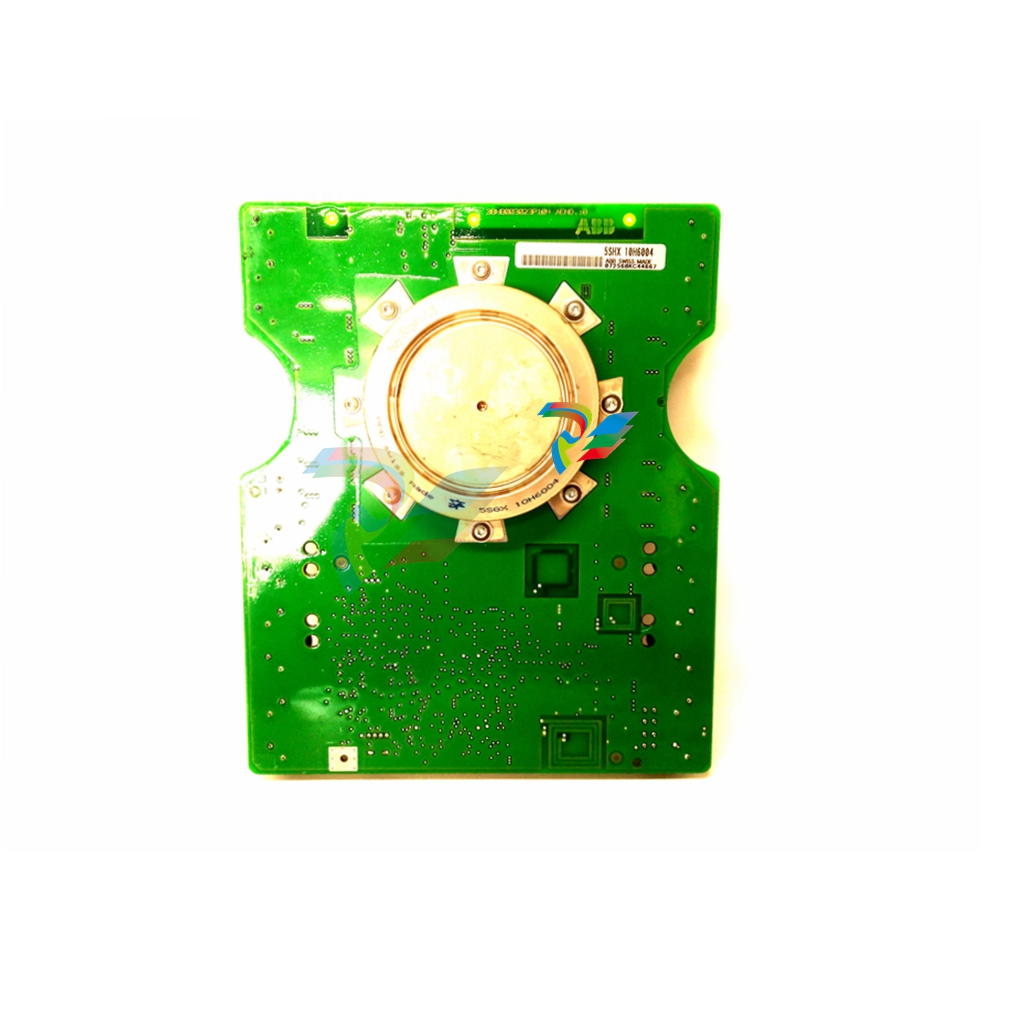

ABB POC01 Control Panel Coupler POC 01 H&B Contronic

Basic introduction

ABB POC01 Control Panel Coupler POC 01 H&B Contronic is a control panel coupler designed by ABB for the H&B Contronic system. It plays a key role in connecting and coordinating the different control components in the system, allowing the various control panel devices to communicate and interact effectively with the system.

Functional features

Connectivity

Strong device interconnectivity: It is able to connect multiple control panel devices (e.g. operating keyboards, displays, indicators, etc.) to the main controller of the H&B Contronic system. Its interfaces enable physical connections between devices, ensuring that signals can be transmitted smoothly between them. For example, it can accurately transmit the commands entered by the operator via the keyboard to the main controller, and at the same time pass on the information fed back from the main controller (e.g., the status of the device is shown on the display) to the corresponding display device.

Multiple Interface Support: Equipped with multiple types of interfaces to accommodate the connection needs of different control panel devices. These interfaces may include standard industrial interfaces such as RS-232 interface, RS-485 interface, USB interface, as well as VGA interface, HDMI interface for connecting to the monitor. This multi-interface design makes it compatible with a wide range of common control panel devices, making it easy for users to carry out system expansion and device updates.

Signal Conversion and Coordination Function

Signal Adaptation and Conversion: In the process of connecting different devices, various signals are adapted and converted. For example, different devices may use different signal protocols, level standards, or data formats; the POC01 Control Panel Coupler can convert these different signals into a uniform format that the system can understand and process, and at the same time convert the signals from the system into the format required by each device. This ensures that the various devices in the entire system are able to communicate correctly with each other without malfunctioning due to incompatible signals.

Signal Coordination and Synchronization: Coordinates the transmission of signals between different devices to ensure that they are consistent in time and sequence. In a complex control system, multiple devices may simultaneously send signals to the system or wait for feedback signals from the system. The coupler can make reasonable queuing and scheduling of these signals to avoid signal conflict and confusion. For example, when an operator rapidly enters multiple commands on the keypad, it delivers these commands to the system in the correct order and ensures that the system's response to each command is correctly fed back to the appropriate device.

System Compatibility and Stability

Deep compatibility with the H&B Contronic system: It is tightly integrated with the H&B Contronic system and fully understands and follows the system's communication rules and protocols. It is designed and functionally adapted to this specific system, so there are no compatibility issues when working with other components in the system. This deep compatibility ensures the stability and reliability of the whole system, enabling the system to run efficiently.

Strong anti-interference ability: In industrial environments, there are various kinds of electromagnetic interference and noise. the POC01 Control Panel Coupler adopts effective anti-interference measures, such as signal shielding, filtering and other technologies, to ensure the accuracy of signal transmission. Even in the harsh electromagnetic environment, such as large motors, inverters and other equipment nearby to generate strong electromagnetic interference, it can work stably to ensure that the communication between the control panel equipment and the system is not affected.

Technical Parameters

Interface characteristics

Number and type of interfaces: There are many different types of interfaces, the specific number and type depends on the actual application requirements. For example, there may be 2 - 3 RS-232 interfaces, 1 - 2 USB interfaces, 1 VGA interface and 1 HDMI interface. The distribution and specification of these interfaces are designed to facilitate device connection and system layout.

Interface communication rates: Each interface has a corresponding communication rate range. For data transmission interfaces, such as RS-232 and USB interfaces, the communication rate is generally between 9600bps - 115200bps, which can meet the data transmission speed requirements of different devices. For video interfaces, such as VGA and HDMI interfaces, they can support a variety of standard video resolutions and refresh rates, such as the VGA interface supports 640×480 - 1920×1080 resolution, 60Hz - 75Hz refresh rate, and the HDMI interface supports higher resolutions and refresh rates to adapt to different display devices.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923