K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

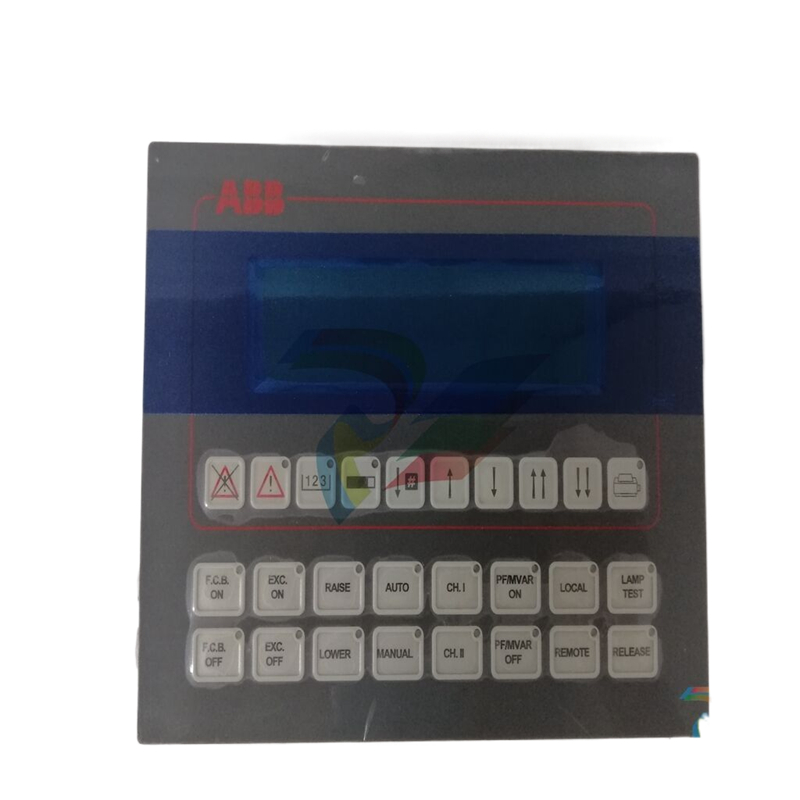

ABB STT02E Hand Held Smart Transmitter Terminal

Basic Information

Product Code: STT02E.

Place of origin: Sweden.

Size: 5.0 inches × 2.0 inches × 8.0 inches, that is, 12.7cm × 5.1cm × 20.3cm.

Weight: 1 lb 3.0 oz, about 0.5kg.

Included Components: PM891 CPU Module, TB850 CEX - Bus Terminator, TB853 RCU Control Link Terminator.

Technical specifications: 450MHz, 256MB.

Functional features

Intelligent Transmitter Function: As an intelligent transmitter terminal, it is capable of communicating with various transmitters to achieve accurate measurement and transmission of industrial process parameters, such as temperature, pressure, flow and other physical quantities, and accurately transmit these data to the control system for further analysis and processing.

Handheld Portability: Its compact and lightweight design makes it convenient for operators to use it anywhere and anytime at the industrial site, and it can be easily carried to different monitoring points for on-site data collection and parameter setting, without having to return to the control room for operation, which greatly improves work efficiency.

Compatibility and Integration: Designed for ABB Bailey Infi 90 system, it has good compatibility with other components of the system, and can be seamlessly integrated into Infi 90 and Net 90 system architectures to ensure the stable operation of the entire control system and smooth data interaction.

Convenience of operation: Equipped with an intuitive user interface and easy-to-understand operation buttons, even non-professional technicians can quickly get started and easily carry out a variety of operations, such as viewing transmitter data, setting parameters, diagnosing malfunctions, etc., which reduces the likelihood of operational errors and improves the usability of the equipment.

Data processing and storage capacity: with a certain amount of data processing capacity, it can carry out preliminary analysis and processing of the collected data, such as data filtering, alarm judgement and so on. At the same time, it can also store a certain amount of historical data, which is convenient for users to view and compare at any time, and helps to analyse the operating trend of the system and the cause of failure.

Application Fields

Industrial automation field: Widely used in chemical industry, electric power, petroleum, natural gas and other types of industrial automation production process, for field equipment debugging, maintenance and fault diagnosis. Operators can communicate directly with the transmitter through STT02E to quickly obtain information on the operating status of the equipment, find and solve problems in a timely manner, and ensure the stable operation of the production process.

Energy management system: It can be used for on-site management of energy metering equipment and monitoring equipment in energy production, transmission and distribution, such as power plants and substations. Through the terminal, you can view the changes of energy parameters in real time, and carry out accurate statistics and analysis of energy consumption, providing powerful support for energy management and energy saving.

Process control system: For pharmaceutical, food and beverage industries that require strict process control, STT02E can help engineers and operators better monitor key parameters in the production process to ensure the stability and consistency of product quality. It can also be used to quickly configure and commission newly installed transmitters during system upgrades and retrofits, shortening project implementation cycles.

Maintenance

Regular cleaning: Due to the harsh environment of the industrial site, dust, oil and other impurities are easily attached to the surface of the terminal and the interface, regularly use a clean and soft cloth to wipe the terminal, to keep the appearance clean, to prevent impurities from entering the internal equipment to affect the normal operation.

Inspection of connecting parts: Regularly check whether the connecting lines, plugs, sockets and other parts between the terminal and transmitter are loose, corroded or damaged, and replace or repair them in time if there are any problems to ensure reliable connection and stable signal transmission.

Battery maintenance: If the terminal uses battery power supply, pay attention to the service life and charging status of the battery. Charge the battery regularly in accordance with the requirements of the instruction manual to avoid excessive discharge leading to battery damage. When the terminal is not used for a long time, the battery should be taken out and stored properly.

Software update: Pay attention to the software update information released by ABB, and update the operating system and applications of the terminal in time to obtain better performance, more functions and stronger security, and at the same time fix possible software vulnerabilities and defects.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923