K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:ac800pec@163.com

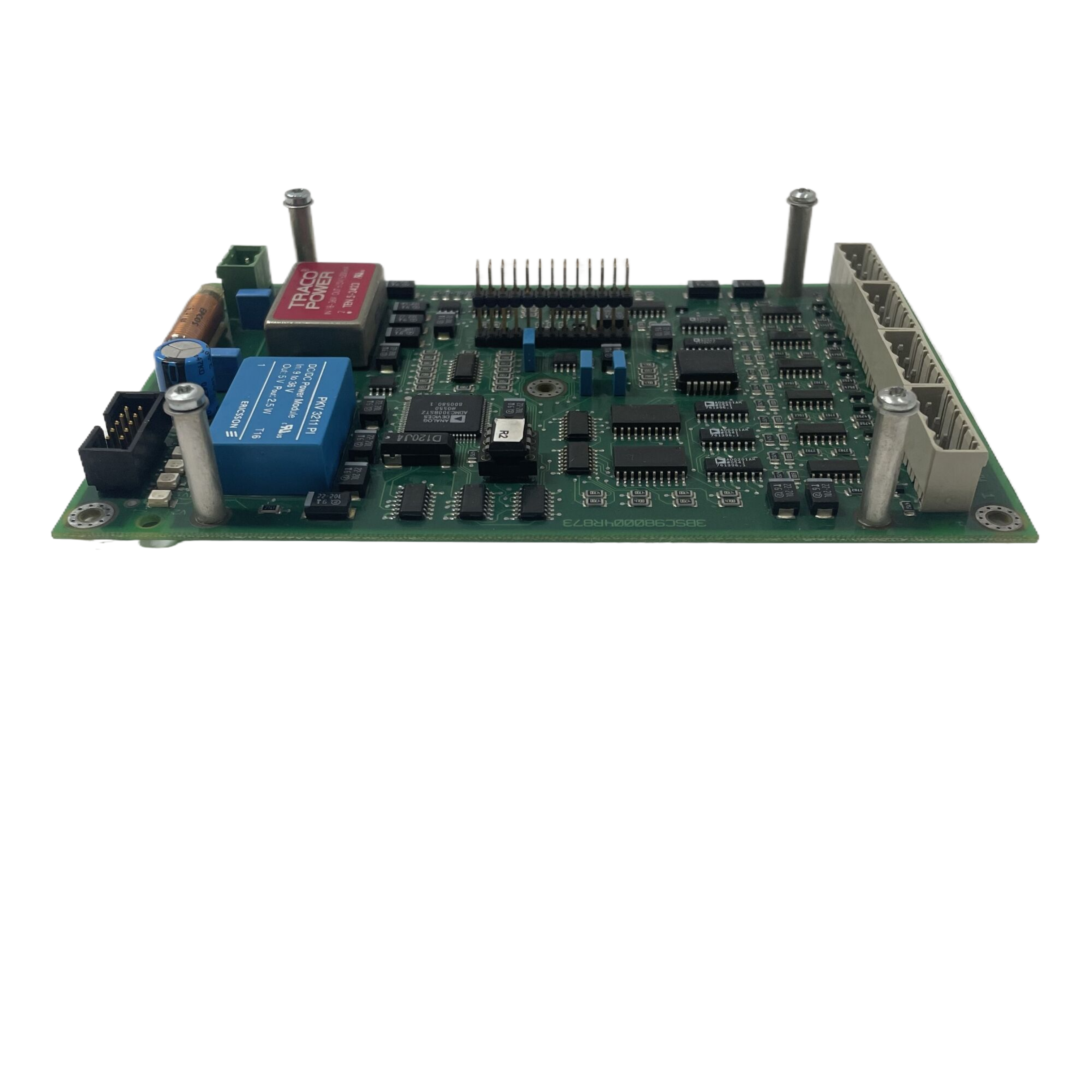

The ABB 3HAB8101-8/08Y and associated part numbers including 3HAC025466-001, 3HAC031683-001, 3HAC14550-2/09A, 3HAC17326-1/02, and 3HNA000512-001 are key components used within ABB industrial robot and automation systems. These components support reliable signal transmission, motion control coordination, system monitoring, and operational stability. Designed to align with ABB robot controller architectures, they are widely applied in automated production lines, robotic cells, and industrial motion control environments where precision and long-term reliability are required.

ABB 3HAB8101-8/08Y Robot Control Components

The ABB 3HAB8101-8/08Y is an important component within ABB industrial robot and automation systems. Together with related part numbers such as 3HAC025466-001, 3HAC031683-001, 3HAC14550-2/09A, 3HAC17326-1/02, and 3HNA000512-001, this product group forms an essential part of ABB’s robot control and system integration architecture. These components are engineered to support accurate signal handling, coordinated motion control, and stable communication between robot subsystems.

ABB industrial robots operate in complex environments where precise coordination between hardware modules is critical. The components listed above are designed to integrate seamlessly into ABB controller cabinets and robot systems, ensuring consistent system behavior during operation. Their design reflects ABB’s long-standing engineering standards for reliability, electrical stability, and compatibility with advanced automation platforms.

System Integration and Functional Role

Within an ABB robotic system, components such as the 3HAB8101-8/08Y and related modules are responsible for supporting core control functions. These include processing internal signals, enabling communication between controller units, and maintaining stable operation of motion and logic tasks. Their role is not limited to a single function but rather contributes to the overall coordination of robotic movement and system responsiveness.

The integration of these components allows ABB robot controllers to manage real-time data exchange between drives, motors, sensors, and control logic. This ensures smooth execution of programmed tasks, precise positioning, and consistent cycle performance. Their standardized interfaces and electrical characteristics allow them to function as part of a unified automation solution.

Design Characteristics

ABB automation components are designed with a focus on long-term operational stability and resistance to industrial environmental conditions. The 3HAB and 3HAC series components follow ABB’s internal design specifications, ensuring compatibility with existing controller systems and robot configurations. Their compact form factor allows efficient use of space within control cabinets while maintaining effective heat dissipation and signal integrity.

Electrical design considerations include stable voltage handling, accurate signal transmission, and resistance to electromagnetic interference commonly found in industrial environments. These characteristics support reliable operation in automated production lines, robotic work cells, and integrated manufacturing systems.

Compatibility with ABB Robot Systems

The ABB 3HAB8101-8/08Y and associated components are commonly used in ABB robot controller platforms where coordinated control and monitoring are required. They are designed to work in harmony with ABB robot arms, drive systems, and controller units. Their compatibility ensures that system integrators and automation engineers can maintain consistent performance across different robot configurations.

By aligning with ABB’s modular system design, these components support scalable automation solutions. Whether used in single-robot cells or larger multi-robot production lines, they contribute to predictable system behavior and simplified system configuration.

Industrial Application Areas

ABB robot control components such as those listed are widely applied across various industries including automotive manufacturing, electronics assembly, metal processing, packaging, and material handling. In these applications, robotic systems must perform repetitive and precise tasks over extended periods. The stability and coordination provided by these components are essential to maintaining production efficiency.

Their use in automated environments supports consistent task execution, reduced system downtime, and improved process repeatability. As part of ABB’s automation ecosystem, they help ensure that robotic systems operate within defined performance parameters.

Maintenance and System Reliability

Reliable operation of robot control components is essential for maintaining overall system uptime. The ABB 3HAB8101-8/08Y and related parts are designed to support long service life when installed and operated according to system specifications. Their standardized design simplifies system diagnostics and maintenance procedures within ABB robot installations.

Consistent performance of these components contributes to predictable system behavior and supports preventive maintenance strategies. This helps automation operators maintain stable production schedules and minimize unexpected interruptions.

Conclusion

The ABB 3HAB8101-8/08Y, together with 3HAC025466-001, 3HAC031683-001, 3HAC14550-2/09A, 3HAC17326-1/02, and 3HNA000512-001, represents a group of essential components within ABB industrial robot and automation systems. Their role in signal processing, system coordination, and operational stability makes them an important part of ABB’s control architecture. Designed to meet ABB’s engineering standards, these components support reliable robotic operation across a wide range of industrial automation applications.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923