K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

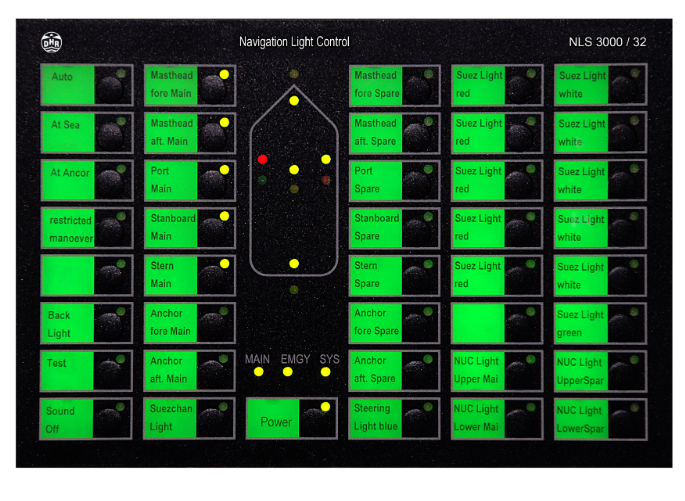

Ship control system

Equipment control system

Power monitoring system

Brand

Description

Introducing the ABB IRB460 DSQC663 – a pinnacle of robotic innovation designed to elevate your automation processes. With its unparalleled precision, robust performance, and adaptability, the IRB460 is engineered to meet the diverse demands of modern industries. This product description explores its key technical features, usage scenarios, and how it stands against other models, while referencing related ABB automation products.

ABB IRB460 DSQC663 - Motor with Pinion, White RAL 9003

ABB IRB460 DSQC663 - Motor with Pinion, White RAL 9003

Introducing the ABB IRB460 DSQC663 – a pinnacle of robotic innovation designed to elevate your automation processes. With its unparalleled precision, robust performance, and adaptability, the IRB460 is engineered to meet the diverse demands of modern industries. This product description explores its key technical features, usage scenarios, and how it stands against other models, while referencing related ABB automation products.

**Key Technical Features**

The ABB IRB460 DSQC663 is built for high-speed and high-precision applications. Key features include:

1. **High Payload Capacity**: With a maximum payload of up to 60 kg, the IRB460 is capable of handling heavy components without compromising speed or accuracy.

2. **Versatile Reach**: The robot offers a reach of 2400 mm, making it suitable for a wide range of tasks, from assembly to material handling.

3. **Advanced Control System**: Equipped with ABB's state-of-the-art IRC5 controller, the IRB460 ensures smooth motion control and easy programming, enhancing productivity and operational efficiency.

4. **Compact Design**: Its compact size allows for integration into tight spaces, making it ideal for facilities with limited floor space.

5. **Speed and Efficiency**: The IRB460 is designed for rapid movements and quick cycle times, making it perfect for high-demand environments such as electronics, automotive, and consumer goods manufacturing.

6. **Durability**: Built from high-quality materials, the IRB460 is engineered to withstand harsh industrial environments, ensuring longevity and reliable performance.

These features collectively make the ABB IRB460 DSQC663 an indispensable asset for industries focused on automation and efficiency.

**Usage Scenarios**

The ABB IRB460 DSQC663 is versatile and can be utilized in various scenarios:

1. **Automotive Manufacturing**: Ideal for tasks such as welding, painting, and assembly, the IRB460 enhances productivity on assembly lines while maintaining high precision.

2. **Electronics Assembly**: Its precision and speed make it suitable for handling delicate components, ensuring high-quality assembly and reducing the risk of damage.

3. **Packaging and Palletizing**: The robot can efficiently package products and arrange them on pallets, significantly speeding up logistics operations.

4. **Material Handling**: The high payload capacity allows it to move heavy materials from one location to another seamlessly, optimizing warehouse operations.

5. **Food and Beverage Industry**: With its ability to operate in clean environments, the IRB460 is perfect for tasks such as sorting and packaging food products, adhering to stringent hygiene standards.

**Comparison with Other Models**

When comparing the ABB IRB460 DSQC663 with other models in the ABB lineup, such as the ABB IRB 2600 and ABB IRB 2400, several distinctions arise:

- **Payload Capacity**: The IRB460's 60 kg payload significantly outperforms the IRB 2600 and IRB 2400, which offer lower payloads, making it more suitable for heavy-duty applications.

- **Speed**: The IRB460 is engineered for faster cycle times, which is crucial in high-throughput environments. In contrast, while the IRB 2600 is efficient, it does not match the IRB460 in speed.

- **Reach**: With a reach of 2400 mm, the IRB460 provides greater flexibility compared to the IRB 2400, which has a shorter reach, thus limiting its application in certain scenarios.

- **Control System**: While the IRB 2400 and IRB 2600 also utilize the IRC5 controller, the IRB460's optimized algorithms enhance motion control, yielding improved operational efficiency.

Overall, the ABB IRB460 DSQC663 stands out for its robust capabilities, making it the preferred choice for industries seeking to maximize productivity and efficiency.

**Reference to Related Models**

For those looking to expand their automation capabilities, the ABB IRB460 DSQC663 can be complemented by various other ABB automation products:

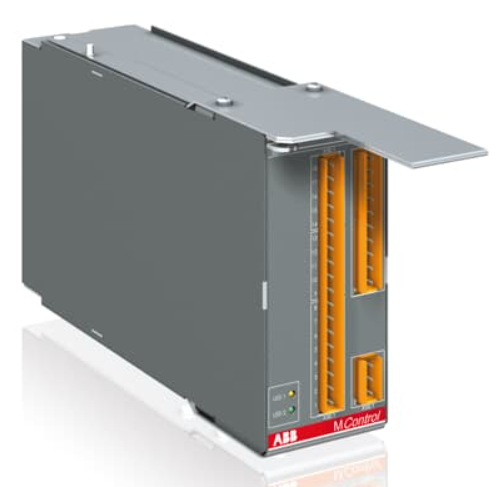

1. **ABB UNS1860B-P**: A versatile controller designed for managing complex automation tasks.

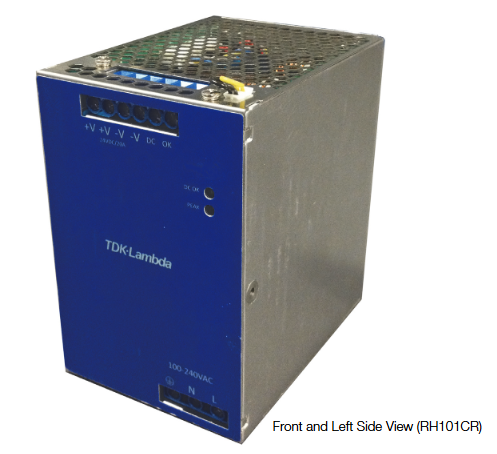

2. **ABB PPE100A 3BHE037824R0101**: A reliable power supply unit for robotics applications.

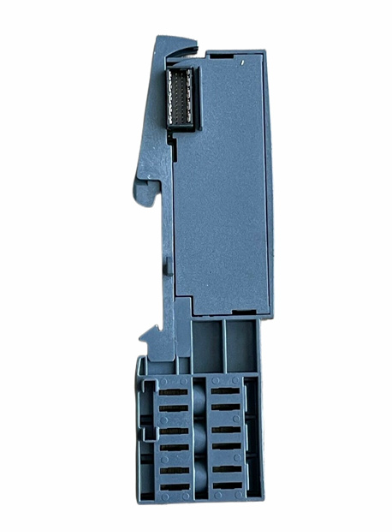

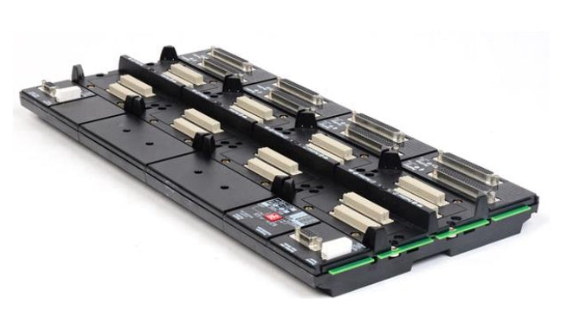

3. **ABB TU852 S800 I/O**: A module for seamless integration of sensors and actuators.

4. **ABB PM511V16 3BSE011181R1**: A powerful motion control module that enhances the performance of robotic systems.

5. **ABB DSQC352B**: An advanced interface for connecting multiple devices in an automation setup.

6. **ABB ACS880-01-246A-3 3ABD00035954-D**: A flexible drive solution that complements the IRB460 for optimal energy efficiency.

7. **ABB IRB140 Series**: An agile robot ideal for low-payload applications.

8. **ABB TB820-1 3BSE008556R1**: A terminal block that enhances the electrical connectivity of robotic systems.

9. **ABB SDCS-PIN-51 | 3BSE004940R1**: A controller designed for industrial automation.

10. **ABB HESG447308R0002 | 70EA02A**: An essential component for ensuring operational reliability in automation systems.

**Conclusion**

The ABB IRB460 DSQC663 is a powerful and versatile robotic solution designed to meet the evolving demands of modern industries. With its high payload capacity, advanced control system, and compact design, it enhances productivity while maintaining precision. Whether in automotive manufacturing, electronics assembly, or material handling, the IRB460 proves to be an invaluable asset. When combined with an array of ABB automation products, it ensures a comprehensive automation solution that addresses the diverse needs of today's industrial landscape. Choose ABB IRB460 DSQC663 for a future where efficiency, reliability, and innovation converge.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information