K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Description

Introducing the ABB IRB 7600 3HAC032140-001 Tethered Manipulators & IRB 7600 3HAC17484-2, the pinnacle of robotic automation technology designed for industries requiring heavy lifting and precise manipulation. As part of ABB's renowned lineup of automation products, the IRB 7600 series boasts cutting-edge features that enhance productivity, efficiency, and operational safety in a variety of applications.

ABB IRB 7600 3HAC032140-001 Tethered Manipulators & IRB 7600 3HAC17484-2 - Advanced Industrial Control Solutions

ABB IRB 7600 3HAC032140-001 Tethered Manipulators & IRB 7600 3HAC17484-2 - Advanced Industrial Control Solutions

Introducing the ABB IRB 7600 3HAC032140-001 Tethered Manipulators & IRB 7600 3HAC17484-2, the pinnacle of robotic automation technology designed for industries requiring heavy lifting and precise manipulation. As part of ABB's renowned lineup of automation products, the IRB 7600 series boasts cutting-edge features that enhance productivity, efficiency, and operational safety in a variety of applications.

Key Technical Features

The ABB IRB 7600 is engineered with exceptional performance characteristics that make it suitable for diverse industrial environments. Key features include:

1. **High Payload Capacity**: The IRB 7600 supports a payload capacity of up to 300 kg, making it ideal for handling heavy components in automotive, aerospace, and manufacturing sectors.

2. **Extended Reach**: With a reach of up to 3.2 meters, these manipulators can easily access far-reaching areas within a workspace, reducing the need for multiple robots and improving operational efficiency.

3. **Precision and Repeatability**: Designed for high precision, the IRB 7600 offers a repeatability of +/- 0.05 mm, ensuring that products are consistently handled with accuracy, which is crucial for quality control.

4. **Robust Construction**: Built with a rigid, robust structure, the IRB 7600 is capable of withstanding the rigors of heavy-duty applications while maintaining high performance and reliability.

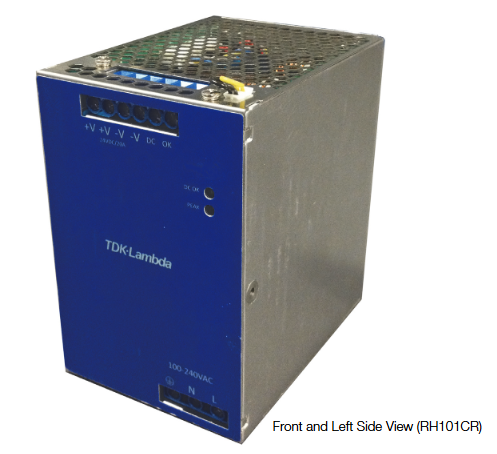

5. **Advanced Control Systems**: With ABB's advanced motion control technology, the IRB 7600 is equipped with sophisticated software that allows for easy programming and integration into existing systems, enhancing operational flexibility.

6. **Tethered Manipulation**: The IRB 7600 models come with tethered manipulation capabilities, which enable seamless communication and control, ensuring optimal performance in synchronized tasks.

Usage Scenarios

The ABB IRB 7600 series is versatile, making it suitable for a range of applications across different industries:

- **Automotive Industry**: Ideal for assembling, welding, and material handling tasks, the IRB 7600 can efficiently manage components like car frames and engines, significantly reducing cycle times and labor costs.

- **Aerospace Manufacturing**: The precision and heavy lifting capabilities of the IRB 7600 make it perfect for handling large and delicate aerospace components, ensuring safety and accuracy in assembly.

- **Heavy Equipment Production**: In industries that manufacture heavy machinery, the IRB 7600 can streamline processes by moving bulky parts with ease, improving throughput and operational efficiency.

- **Metal Fabrication**: The IRB 7600 is also equipped to handle metal parts in fabrication processes, from cutting to assembly, ensuring consistent quality and precision.

- **Logistics and Warehousing**: With its payload capabilities, the IRB 7600 can be utilized in logistics for sorting, stacking, and transporting goods in a warehouse environment.

Comparison with Other Models

When compared to other ABB models, such as the ABB IRB 2600 and the ABB IRB 2400/1403/CR3, the IRB 7600 stands out due to its superior payload capacity and reach. The IRB 2600 offers a maximum payload of 20 kg and a reach of 1.65 meters, making it suitable for lighter tasks compared to the heavy-duty capabilities of the IRB 7600. Similarly, the IRB 2400 series is designed for versatile applications but lacks the extensive payload capacity that the IRB 7600 provides.

In contrast to the ABB UNS1860B-P, which is primarily suited for smaller, precision tasks, the IRB 7600 is tailored for heavy lifting and larger-scale operations, making it a more robust choice for industries with demanding requirements.

Reference to Related Models

The ABB IRB 7600 series complements a wide range of ABB automation products. Some related models include:

1. **ABB IRB 2400/1403/CR3**: Suitable for general-purpose applications with lower payload requirements.

2. **ABB IRB 2600**: Designed for tasks requiring moderate payload and reach.

3. **ABB IRB 6700**: Offers a larger payload and reach for handling heavier components.

4. **ABB IRB 6700**: Ideal for heavy-duty applications with extended reach.

5. **ABB IRB 6700**: Designed for versatile applications with robust payload capabilities.

6. **ABB 07DC91**: A controller that enhances the operational capabilities of ABB robots.

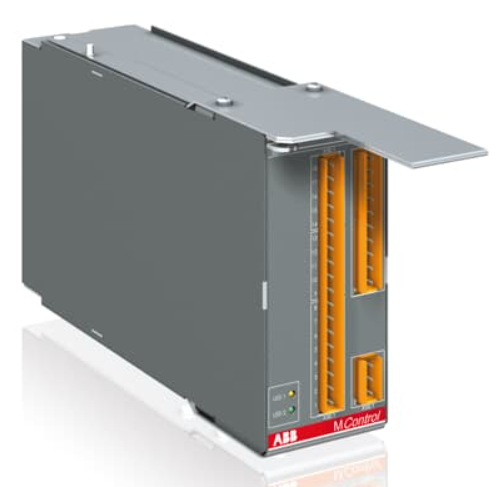

7. **ABB PM864AK01**: A control module that optimizes performance in robotic applications.

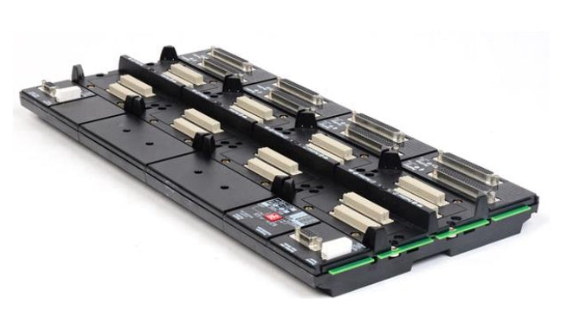

8. **ABB SDCS-PIN-51**: A signal connection device for seamless integration with ABB robots.

9. **ABB GINT5611C**: An interface module that facilitates communication between various ABB products.

10. **ABB ACS880-01-246A-3**: An automation product that enhances energy efficiency in robotic operations.

In conclusion, the ABB IRB 7600 3HAC032140-001 Tethered Manipulators & IRB 7600 3HAC17484-2 is a high-performance robotic solution designed for industries that demand precision, reliability, and heavy lifting capabilities. Its advanced features and versatility make it an ideal choice for a variety of applications, from automotive to aerospace. By integrating ABB's automation products, businesses can enhance their productivity and operational efficiency, ensuring they remain competitive in today's fast-paced industrial landscape.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information