K-WANG

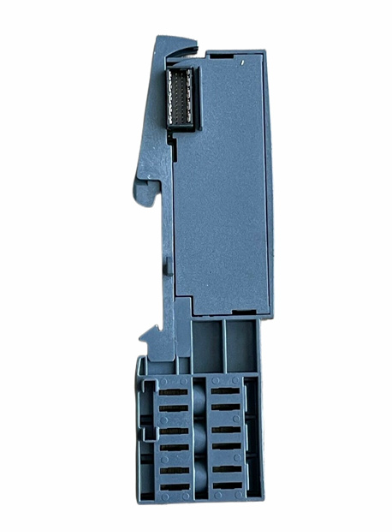

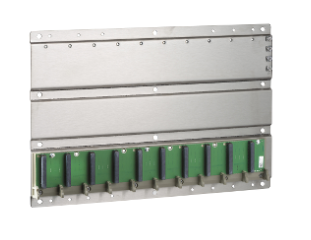

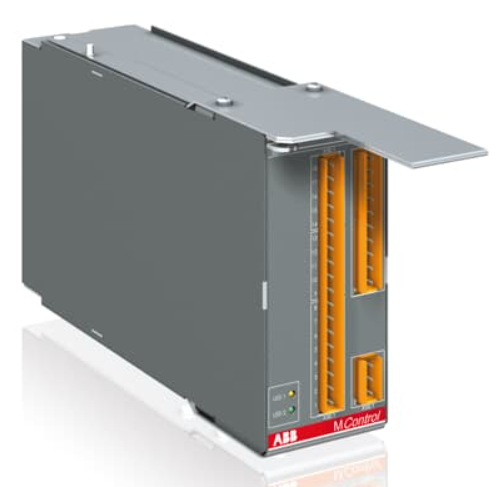

ABB T-1521Z - Terminal Module

The ABB T-1521Z is a high-performance automation controller designed to meet the rigorous demands of the power industry, petrochemical sector, and general automation applications. Renowned for its robust input/output (I/O) capacity, exceptional durability, and superior performance metrics, the T-1521Z stands out as a reliable solution for complex industrial processes requiring precise control and seamless integration.

At its core, the ABB T-1521Z features an extensive I/O interface capable of managing a wide array of analog and digital signals. This flexibility allows it to handle diverse sensor inputs and actuator commands essential for real-time monitoring and control. The controller supports high-speed data processing with minimal latency, ensuring timely execution of automation tasks. Engineered for harsh environments, the T-1521Z boasts a rugged construction designed to withstand extreme temperatures, vibrations, and electromagnetic interference, making it ideal for continuous operation in demanding settings such as power plants and petrochemical facilities.

Performance-wise, the ABB T-1521Z delivers precise control algorithms and supports advanced communication protocols, including industrial Ethernet and fieldbus technologies. This connectivity enables seamless integration with supervisory control and data acquisition (SCADA) systems and distributed control systems (DCS), facilitating centralized monitoring and management of industrial processes. The controller also incorporates built-in diagnostic tools and fault tolerance mechanisms, reducing downtime and enhancing operational reliability.

In real-world applications, the ABB T-1521Z excels in scenarios where complex process automation is critical. In the power industry, it is commonly deployed for turbine control, generator management, and grid automation, ensuring optimal efficiency and safety. Within petrochemical plants, the T-1521Z manages process variables such as temperature, pressure, and flow rates with high accuracy, contributing to product quality and environmental compliance. For general automation, its versatility supports manufacturing lines, packaging systems, and material handling operations, where precision and responsiveness are paramount.

When compared to other ABB automation products, the T-1521Z offers distinctive advantages in terms of scalability and integration. For instance, while the ABB PM866 is a powerful process control unit suited for specific loop control applications, the T-1521Z provides broader I/O capabilities and enhanced communication options, making it more adaptable to complex system architectures. Similarly, unlike the ABB DSQC313, which is primarily focused on robotics drive control, the T-1521Z covers a wider range of automation tasks, from process control to discrete manufacturing.

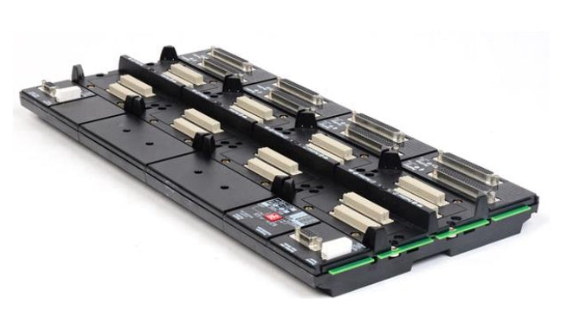

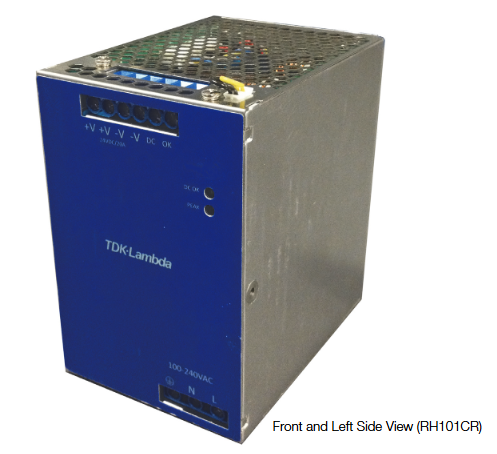

Alongside the ABB T-1521Z, ABB offers complementary models such as the ABB PFEA112-20 3BSE030369R0020, which serves as a reliable operator interface, and the ABB CP-E 24/1.25 power supply module that ensures stable and efficient energy delivery to automation components. The ABB DI651 input module extends the digital input capacity for large-scale systems, while the ABB 3ASC25H705/-7 provides specialized control functions in high-demand environments. For advanced monitoring and protection, the ABB RET670 1MRK004816-AC relay protection system complements the T-1521Z by safeguarding critical infrastructure.

Other ABB components like the ABB DSCS131 57310001-LM automation interface and the ABB DSDP170 57160001-ADF processing unit integrate smoothly with the T-1521Z, creating a cohesive and scalable automation ecosystem. The ABB LWN2660-6E 3BHL000986P7002 communication module further enhances system connectivity, facilitating data exchange across distributed control networks. Additionally, the ABB FAZ-C6/1 circuit breaker and ABB 07KR51 220VDC power modules provide essential electrical protection and power management, supporting uninterrupted operation of T-1521Z-based systems.

The application of the ABB T-1521Z in power industry, petrochemical, and general automation environments is supported by its robust design, extensive functionality, and seamless compatibility with other ABB automation products. Whether controlling critical power generation equipment or managing complex chemical processing lines, the T-1521Z delivers reliable, high-precision automation that drives operational efficiency and safety.

By integrating the ABB T-1521Z with complementary devices like the ABB GMKP2800-32IBY monitoring system and the ABB AI801 analog input module, users can build tailored automation solutions that meet specific industry requirements. This holistic approach to industrial automation underscores ABB’s commitment to providing scalable, durable, and cutting-edge automation technology for a wide range of applications.

In summary, the ABB T-1521Z stands as a cornerstone product within ABB’s extensive portfolio of automation solutions. Its superior I/O capacity, rugged durability, and advanced communication capabilities make it an indispensable asset for industries demanding reliable and precise control. Supported by a suite of complementary ABB devices, the T-1521Z enables seamless integration and optimized performance, reinforcing ABB’s leadership in the automation sector. Keywords such as "ABB T-1521Z", "ABB automation products", and "application of T

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|