K-WANG

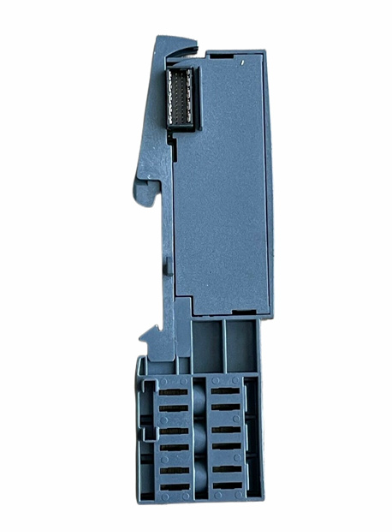

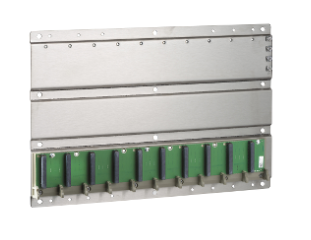

EMERSON Ovation - 1C31113G05 Analog Input Module for 5VDC/0-20mA Signal

The EMERSON Ovation system stands as a premier solution in the landscape of industrial automation, specifically engineered to meet the rigorous demands of the power industry, petrochemical sectors, and general automation applications. Renowned for its robust architecture and advanced control capabilities, the EMERSON Ovation platform delivers unmatched reliability and performance, making it a preferred choice for complex process control environments.

At its core, the EMERSON Ovation system boasts a highly scalable input/output capacity, supporting thousands of I/O points across diverse modules. This flexibility allows it to seamlessly integrate with a wide array of field devices, including analog and digital sensors, actuators, and transmitters. The system’s architecture is designed for high availability, featuring fault-tolerant controllers and redundant communication paths that ensure continuous operation even under adverse conditions. Performance-wise, the Ovation system excels with deterministic control cycles measured in milliseconds, enabling precise and timely process adjustments critical in power generation and petrochemical processing.

Durability and environmental resilience are another hallmark of the EMERSON Ovation. The hardware modules are engineered to withstand harsh industrial environments, including extreme temperatures, electromagnetic interference, and vibration, ensuring long-term operational stability. This ruggedness is complemented by advanced diagnostics and predictive maintenance tools, which minimize downtime through proactive system health monitoring.

In real-world applications, the EMERSON Ovation system shines in power industry scenarios such as thermal, hydroelectric, and nuclear power plants, where precise control of turbines, boilers, and safety systems is paramount. Its ability to handle complex logic and interlocks makes it ideal for petrochemical plants, where safety and regulatory compliance are critical. For general automation, Ovation’s modularity and extensive protocol support facilitate integration into existing infrastructures, supporting everything from batch processing to continuous manufacturing lines.

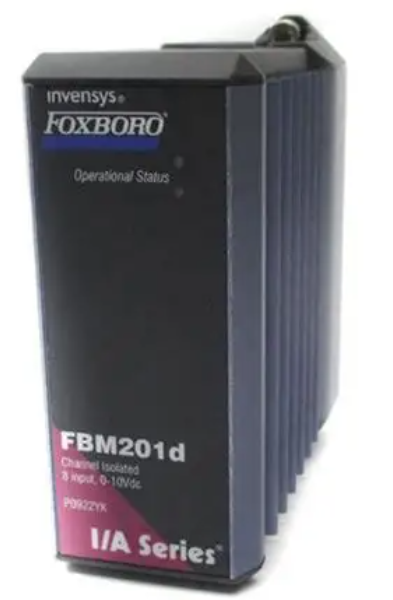

When compared to other EMERSON automation products, the Ovation system stands out for its comprehensive control capabilities combined with superior scalability and fault tolerance. For example, while the EMERSON DeltaV CE4003S2B6 Analog Input Module excels in analog signal acquisition within the DeltaV distributed control system, Ovation’s integrated control environment provides a broader scope of control and monitoring tailored for power and petrochemical plants. Similarly, modules like the EMERSON KJ4001X1-BE1 and KJ2003X1-BA2 offer specialized interface solutions but do not match Ovation’s system-wide robustness and application-specific optimizations.

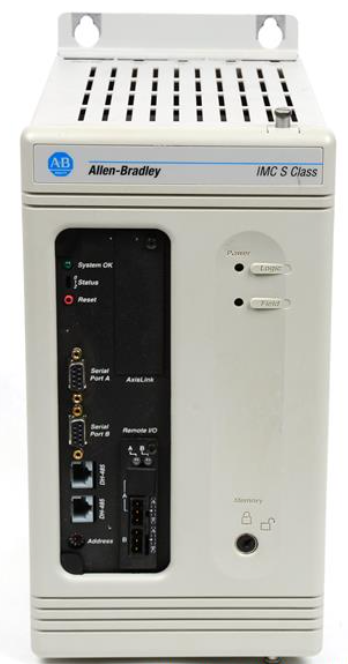

Alongside the EMERSON Ovation, complementary products such as the EMERSON 5A26479G03 and 5A26479G02 modules provide additional I/O capacity and redundancy options, enhancing system flexibility. The EMERSON VE3007 MX Controller and VE4007 offer high-performance processing units that integrate seamlessly with Ovation for distributed control applications. For sensor integration, the EMERSON PR6424/000-121 Eddy Current Sensor and PR6423/003-031 provide precise vibration and speed monitoring critical to maintaining machinery health within Ovation-controlled plants. The EMERSON KJ3221X1-EA1 12P2534X022 Proximity Sensor and PR6424/006-010 Proximity Sensor extend the system’s real-time detection capabilities. Furthermore, the EMERSON MMS6822 and EPRO PR6423/002-001 CON041 Vibration Transmitter are essential for predictive maintenance, ensuring the Ovation system operates at peak efficiency.

The application of Ovation in the power industry is highlighted by its unparalleled ability to manage complex turbine control, boiler management, and safety shutdown systems, all while maintaining stringent compliance with industry standards. In petrochemical plants, Ovation’s real-time data processing and alarm management facilitate safe and efficient chemical reactions and material handling. For general automation, its modular design and open communication protocols enable seamless integration with existing plant infrastructure and third-party devices, driving operational excellence and scalability.

In essence, the EMERSON Ovation system represents a fusion of cutting-edge technology and industrial-grade durability, delivering a comprehensive automation solution tailored to the demanding requirements of power generation, petrochemical processing, and general automation sectors. Its extensive integration capabilities, combined with complementary EMERSON automation products such as the DeltaV Analog Input modules, VE series controllers, and advanced sensor technologies, position Ovation as a cornerstone platform for modern industrial control systems. Whether upgrading legacy systems or designing new plants, the Ovation system ensures operational reliability, enhanced safety, and optimized performance across critical industrial applications.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|