K-WANG

EMERSON PR6426/010-110 CON021/916-240 Eddy Current Sensor - Precision Measurement for Industrial Control Systems

The EMERSON PR6426/010-110 CON021/916-240 Eddy Current Sensor represents a pinnacle in precision and reliability within the field of non-contact vibration and displacement measurement. Engineered to meet the demanding requirements of the power industry, petrochemical plants, and general automation environments, this sensor delivers outstanding performance through advanced eddy current technology. Its robust design and superior input/output capabilities ensure accurate data acquisition even in the harshest industrial conditions.

Key technical features of the EMERSON PR6426/010-110 CON021/916-240 Eddy Current Sensor include a wide input range compatible with various probe types, enabling precise measurement of shaft vibration and position. The sensor supports high-frequency operation up to several kilohertz, providing real-time monitoring critical for predictive maintenance and machine protection systems. Its rugged construction is designed to withstand extreme temperatures, moisture, and electromagnetic interference, ensuring durability and consistent performance over extended periods. The sensor’s output signal is optimized for seamless integration with EMERSON automation products, facilitating reliable communication with control systems such as the DeltaV series and other process control platforms.

In real-world applications, the PR6426/010-110 CON021/916-240 excels in environments where continuous monitoring of rotating equipment is vital. In the power industry, it is frequently deployed for turbine shaft vibration analysis, helping to detect early signs of imbalance or misalignment that could lead to costly downtime. Within the petrochemical sector, this sensor plays a crucial role in monitoring pumps, compressors, and motors, where precise vibration data is essential to avoid catastrophic failures. Furthermore, its application in general automation extends to manufacturing plants and other industrial settings where machine condition monitoring is a priority to optimize operational efficiency and reduce maintenance costs.

When compared to other EMERSON models such as the PR6424/010-140 CON021 or the PR6423/004-031 CON021, the PR6426/010-110 CON021/916-240 stands out with enhanced frequency response and improved signal-to-noise ratio, making it ideal for more sensitive applications requiring higher resolution data. Unlike the PR6423/01C-010 CON021 Eddy Current Sensor, which is optimized for lower frequency ranges, the PR6426 variant supports a broader spectrum, offering greater versatility across diverse industrial needs. Additionally, the PR6426 model’s integration capabilities surpass those of the CON041 PR6424/000-121 Eddy Current Sensor by providing more robust output options, thereby simplifying system architecture in complex automation networks.

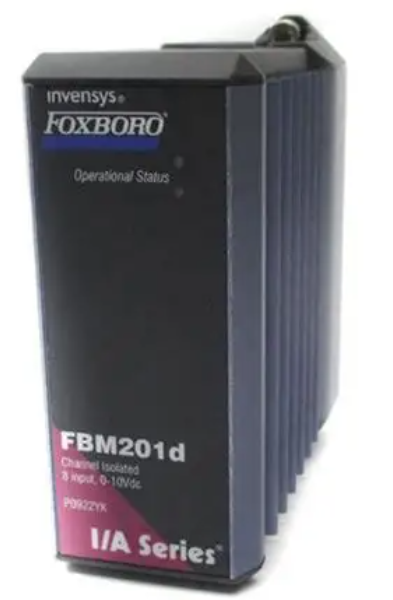

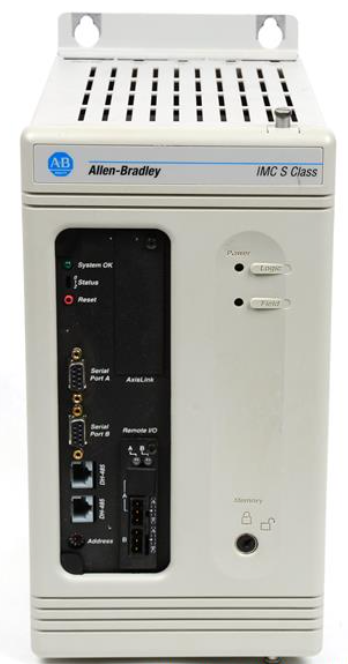

Alongside the EMERSON PR6426/010-110 CON021/916-240 Eddy Current Sensor, we also offer complementary solutions such as the EMERSON MMS6410 and MMS6100 vibration monitors, which provide comprehensive data analysis and alarming functions. The EMERSON Epro PR6423/002-040 CON041 and PR6423/003-031-CN sensors serve as alternatives for applications requiring different measurement ranges or environmental resistance. For control and interface purposes, the EMERSON KJ3208X1-BA1 and DeltaV VE4006P2 KJ3241X1BA1 Redundant Serial Interface Card allow seamless integration of sensor output into advanced control systems. Additionally, models like the EMERSON PR6424/012-000+CON011 and PR6424/004-010 CON021 Eddy Current Sensors provide scalable options within the same product family, ensuring tailored solutions for specific monitoring needs.

The application of the PR6426/010-110 CON021/916-240 Eddy Current Sensor in power industry, petrochemical, and general automation settings leverages EMERSON’s heritage of delivering reliable and innovative automation products. Its ability to provide accurate, real-time data under challenging conditions makes it an indispensable tool for engineers focused on maximizing equipment uptime and operational safety. The sensor’s compatibility with other EMERSON automation products enhances system robustness, enabling predictive maintenance strategies and reducing unplanned outages.

In summary, the EMERSON PR6426/010-110 CON021/916-240 Eddy Current Sensor is a high-performance, durable solution designed for critical industrial applications. Its superior technical capabilities, broad frequency response, and integration flexibility distinguish it from other models within the EMERSON portfolio, such as the PR6423/13R-040 CON021 Eddy Current Sensor and the CON041 PR6424/000-121. By choosing this sensor, industries gain a reliable partner in monitoring rotating machinery health, ultimately supporting safer and more efficient operations across power generation, petrochemical processing, and general automation sectors.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|