K-WANG

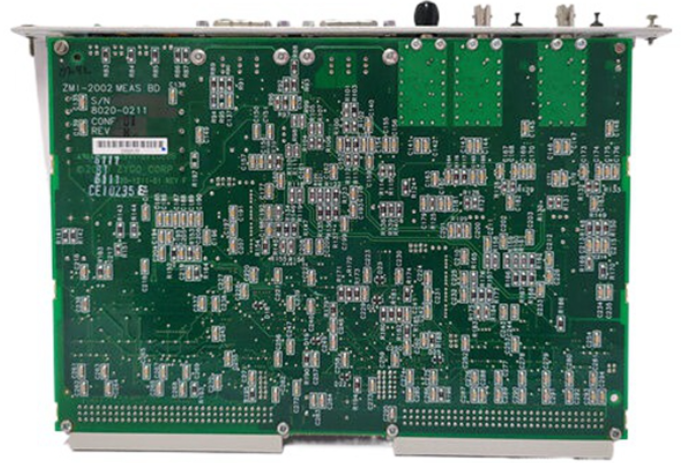

GEC Alstom KCC8302 - Thyristor Rectifier Stack Power Module 20X-1310CRL 30Z-2116 a

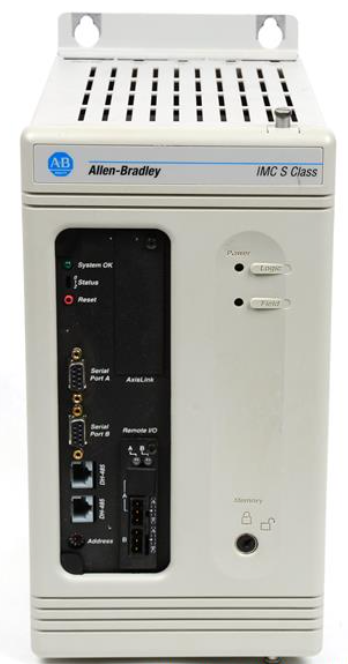

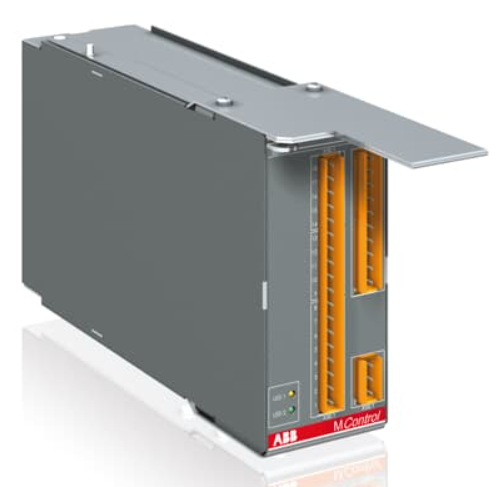

The GEC Alstom KCC8302 is a robust and highly efficient automation controller designed specifically to meet the demanding requirements of the power industry, petrochemical sector, and general automation applications. Engineered with precision, the KCC8302 stands out due to its advanced input/output (I/O) capacity, exceptional durability, and superior performance metrics, making it an indispensable component in complex industrial environments.

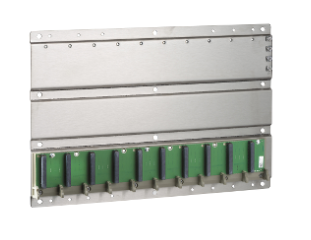

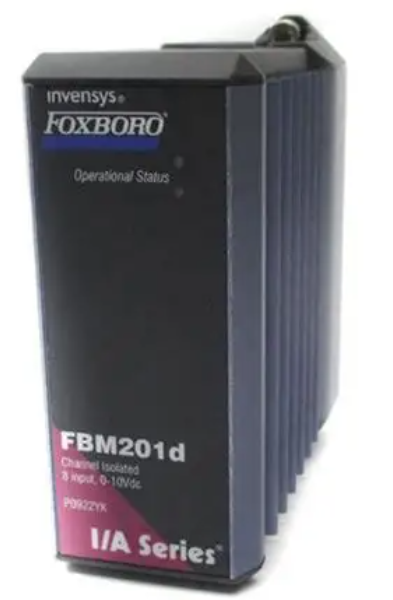

At the core of the GEC Alstom KCC8302 is a versatile I/O interface capable of managing a wide array of digital and analog signals. This module supports high-density I/O configurations, ensuring seamless integration with existing control systems and enabling real-time data acquisition with minimal latency. Its input/output capacity is meticulously optimized to handle multiple simultaneous processes, accommodating up to several hundred I/O points depending on system configuration, which provides scalability for expanding automation needs.

Durability is a hallmark of the KCC8302. Designed to function reliably in harsh industrial conditions, it features ruggedized components that withstand extreme temperatures, vibrations, and electrical noise commonly encountered in power plants and petrochemical facilities. The module’s performance metrics include rapid processing speeds and low power consumption, which contribute to enhanced system efficiency and reduced operational costs. Additionally, it supports fault-tolerant operation, ensuring continuous system availability and minimizing downtime in critical applications.

In real-world usage, the GEC Alstom KCC8302 excels in scenarios requiring precise control and monitoring. In the power industry, it is often deployed for managing turbine control systems, generator protection schemes, and substation automation tasks. Its ability to process high volumes of data in real-time makes it ideal for maintaining grid stability and optimizing power generation. Within petrochemical plants, the KCC8302 facilitates complex process automation, including temperature regulation, pressure monitoring, and safety interlocks, thereby enhancing operational safety and efficiency. For general automation, it offers flexible customization options that allow manufacturers to streamline production lines, improve quality control, and reduce human error.

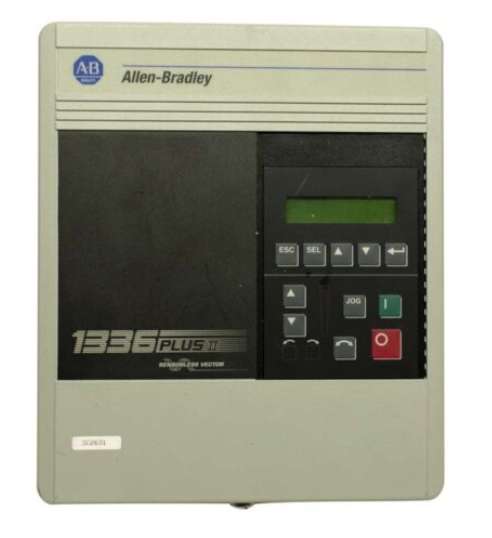

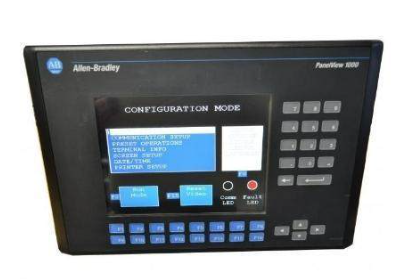

When compared with other GEC Alstom automation products, the KCC8302 presents several unique advantages. Unlike the GEC Alstom MPF1700G356, which is primarily focused on power conversion control, the KCC8302 delivers broader I/O versatility and enhanced processing capabilities. Compared to the GEC Alstom Adjustment Module Keyboard Alspa MV1000, which serves as a user interface for manual control adjustments, the KCC8302 functions as a core automation controller enabling comprehensive system integration. Its rugged design surpasses models like the GEC Alstom Plug-in card Input/Output module SA46623.B, which is optimized for lighter I/O tasks but lacks the scalability and durability required for heavy-duty applications.

Alongside the GEC Alstom KCC8302, complementary products such as the GEC Alstom MV507A2D1A and the GEC Alstom MV504A2D1 offer enhanced modularity for expanded control architectures, while the GEC Alstom Micom P40 agile P541211 B1M0300J provides advanced protection relay functions that integrate seamlessly with the KCC8302 for comprehensive system protection. The GEC Alstom 029146624 unit is another valuable addition for auxiliary control tasks, and the GEC Alstom PB135 module supports additional input/output expansion where needed. For interface and control station needs, the GEC Alstom Joystick Controller Station and the GEC Alstom JOYSTICK Controller Station provide ergonomic operator control solutions that complement the automation backbone established by the KCC8302. Additionally, the GEC Alstom Alspa MV530A4C1A and the GEC Alstom MVTW03D1AA0751B modules extend the system’s communication and protocol handling capabilities, ensuring seamless integration with legacy and modern equipment alike.

The application of KCC8302 in power industry, petrochemical, and general automation environments is further enhanced by its compatibility with GEC Alstom’s extensive ecosystem of control and monitoring devices. This synergy enables end-users to deploy fully integrated automation solutions that maximize operational uptime, improve safety, and deliver precise process control. The KCC8302’s adaptability and ruggedness make it a preferred choice for engineers and system integrators seeking reliable automation products that meet stringent industrial standards.

In summary, the GEC Alstom KCC8302 stands as a cornerstone in industrial automation, delivering unmatched input/output capacity, durability, and performance for critical applications. Its strengths in the power industry, petrochemical plants, and general automation underscore its versatility and resilience. By combining the KCC8302 with other esteemed GEC Alstom automation products such as the MPF1700G356, Adjustment Module Keyboard Alspa MV1000, Plug-in card Input/Output module SA46623.B, and Micom P40 agile, users gain a comprehensive and future-proof automation platform that drives efficiency, safety, and operational

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|