K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

• Improved reliability – TMR controller redundancy provides 2

out of 3 voting to improve reliability and eliminate single-point

communication failures within the control.

GE FANUC Mark* V to Mark* VIe Migration

Overview

GE is proud to provide controls you can trust from experts you

can trust. You can now add significant new performance

enhancements to your Mark V control. GE offers a Mark VIe upgrade

package with many new features and algorithms for new turbine

functions, such as advanced dry low NOx

systems and operational

flexibility (OpFlex*) enhancements. The upgrade includes a

complete modernization of operator stations and networks to

current technology

I/O expandability – flexible and modular architecture allows for

future growth of capabilities and applications.

• Built with cyber security best practices – Achilles™

Communications Certification Level 1 Mark VIe Controllers

feature hardened network switches and HMIs within a segmented

network.

eTechnology Benefits

The Mark VIe provides performance, operability and reliability for

today’s connected plant.

• Increased computational power – advanced technology

Mark VIe processors provide access to sophisticated software

enhancement modules to improve turbine performance, reliability,

and operability.

• Intuitive features – GE’s powerful ToolboxST* software, with

modern drag-and-drop type editors, industry leading trender with

video type forward-reverse-freeze capability, and code-compare

tools.

• Increased operational productivity – user-friendly HMI

graphics, alarm/event management, and trending leading to

improved operator recognition and resolution of system faults.

• Maintenance efficiency improvements – reduced engineering

time due to a single integrated software tool for configuring

networks, processors, and I/O boards, along with editing

application software, managing block libraries, and displaying

system diagnostics.

• Latest GE software libraries – Leverages years of GE OEM

experience to ensure safety-related software updates are

delivered while also retaining the majority of the existing control

system customization.

Hardware Features

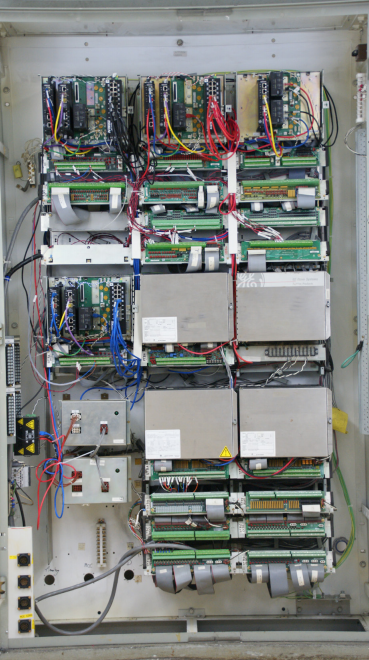

The Mark V to VIe migration consists of a streamlined hardware

configuration to provide the performance capabilities and reliability

to meet the requirements of your operation.

• Reduced downtime – a migration can be done in as few as 9 days

with 5 outage days using the existing cabinet footprint, with no

impact to field wiring or turbine devices. Coordinated installation

between the customer and GE reduces migration time and

provides on-site education during installation.

• Ethernet backbone – provides expandability as well as

protection against control system component obsolescence.

In other words, obsolescence is now handled “componentby-component” rather than “system-by-system.” Modernized

communication conforms to modern IEEE 802.3 standards.

• Lifecycle maintainability – the new Mark VIe boards and the

existing Mark V components not replaced during the migration

process assume the lifecycle and support of the Mark VIe control

system.

Operator Interface

The HMI for the Mark VIe uses a Windows™ operating system. With

this HMI, your existing operator and maintenance stations will have

the latest HMI/SCADA Cimplicity* graphics system featuring easy

screen navigation, alarm/event management and trending tools. In

addition, Windows™ 7 HMIs use the latest versions of ControlST*

and ToolBoxST which will augment your existing Modbus and TCP-IP

GSM links to plant controls.

OpFlex Software Enhancement Modules

GE’s OpFlex software enhancement modules add significant new

performance enhancements to your Mark VIe turbine control to

improve reliability, provide system diagnostics, help to prevent

trips, and improve operator productivity. There are four packages

featuring 20 modules which complement the power of the Mark VIe

control system.

Cyber Security

Upgrading to the Mark VIe control system allows you to take

advantage of GE’s cyber security solutions, helping reduce your risk.

Our cyber security solution provides defense-in-depth protection.

The SecurityST* Mark VIe Solution and Commissioning Services is

Achilles™ Practice Certified – Bronze, indicating the solution has

undergone strict cyber security best practices demonstrating to

customers that systems are developed and implemented securely.

The Security ST appliance and Cyber Asset Protection Subscription

are designed to support the plant operation’s compliance to cyber

security standards and guidelines including NERC CIP, NEI 08-09

and ISA99/IEC 62443.

Controls LifeCare* Partnership

This comprehensive subscription helps to maintain the health

of turbine and plant control, generator control and static starter

systems. Subscribers benefit from GE expertise and a true

partnership in the maintenance and servicing of control systems

with a simple, packaged approach. Controls LifeCare is available in

one-, five- and ten-year agreements and is applicable for both new

and existing units.

Mechanical Solutions Options

GE’s electromechanical solutions are a critical piece of a control

system migration or full panel retrofit. Integration considerations

need to be made based on the age of control system and the

interface with the software and electromechanical components.

GE has the expertise and OEM knowledge to evaluate these needs

to ensure assets remain reliable. Our solutions have the potential to

improve performance, online capability, provide redundancy and fit

within the current operations envelope.

Critical components that need to be evaluated include transducers

and transmitters, fuel valves and fuel skids, and speed sensing.

GE also provides solutions for Trip Manifold Assemblies (TMAs),

Hydraulic Power Units (HPUs), and other assets that are important

to operations. Our experience includes steam, hydro, and gas

turbines as well as balance of plant. We have the application

knowledge to make sure that your assets are upgraded correctly.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923