K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

Eight 24 VDC Inputs, six relay outputs, power supply 120/230V input,

Estimated Shipping Size

Dimensions: 5.0" x 4.0" x 5.0"

(12.7 cm x 10.2 cm x 12.7 cm)

Weight: 1 lbs 14.1 oz (0.9kg )

Tariff Code: 8537109060

Country of Origin: France

Ships from Webster NY, USA

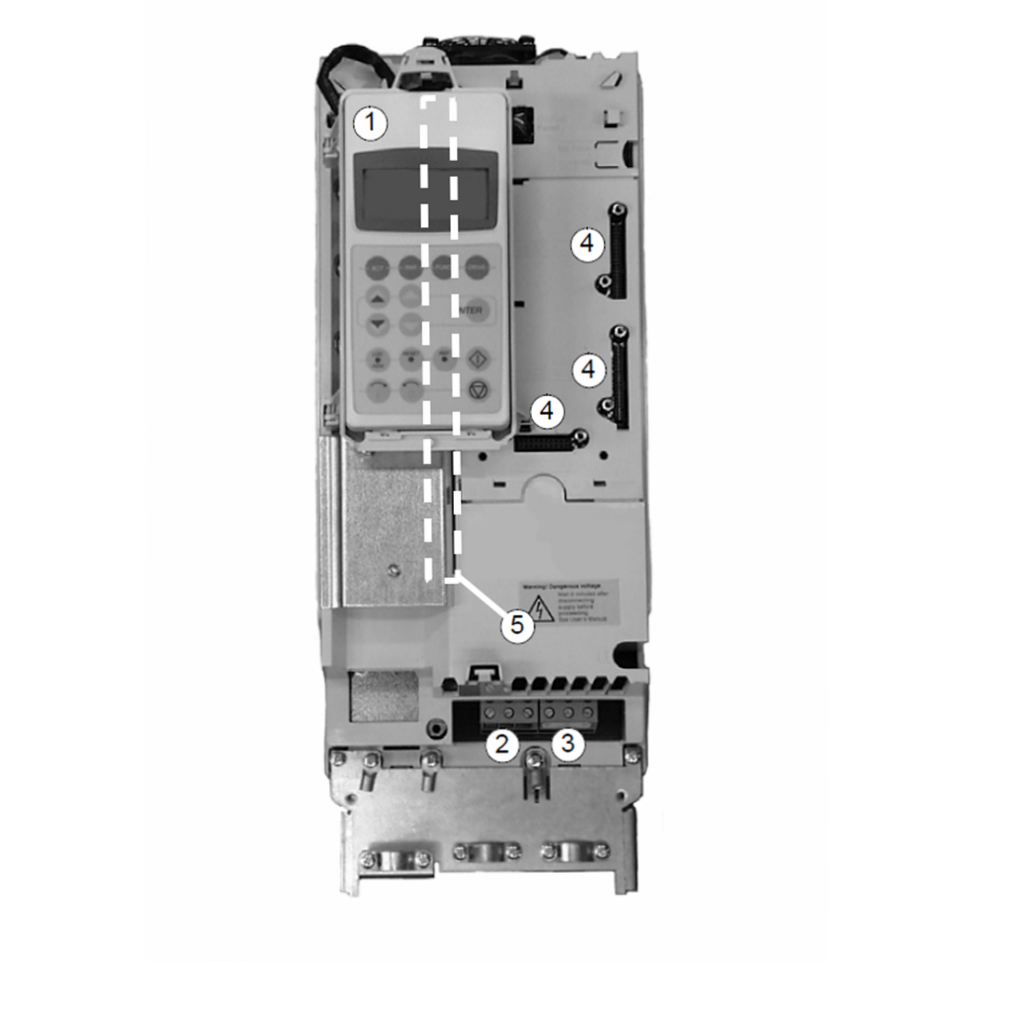

ABB 1SBP260011R1001 Controller 31 Basic Unit

Basic Information

Product Overview:ABB 1SBP260011R1001 Controller 31 Basic Unit is a key component in the ABB automation control system. As a basic unit, it provides the core control function for the whole control system, can receive and process various input signals and output control commands to drive external devices, and is the basis for realising industrial automation processes.

Physical Characteristics: It usually adopts a compact design and is easy to be installed in the control cabinet. The casing is usually made of sturdy metal material with good electromagnetic shielding, which can effectively prevent the influence of external electromagnetic interference on the internal circuitry. Its installation may be rail mounted for easy layout and fixing in the control cabinet.

Functional Characteristics

Processing power

Processor performance: The built-in high-performance processor is capable of quickly executing complex control logic and arithmetic. It can process a large number of input signals and generate accurate output commands in a short period of time to meet the strict requirements of real-time and accuracy in industrial sites. For example, in an automated production line, it can respond quickly to sensor signals, such as position sensors, temperature sensors, etc., so as to accurately control the operating status of equipment.

Multi-tasking capability: Supports multi-tasking, allowing multiple control programmes to be run or multiple control tasks to be performed at the same time. This feature makes it possible to simultaneously take into account the control needs of different devices, such as controlling the speed of multiple motors and the opening of multiple valves at the same time, as well as reasonably allocating system resources to ensure that each task is independent of each other and can run stably. For example, in a chemical production process, it can simultaneously control the temperature regulation of the reactor, the feeding speed of the material and the speed of the stirrer.

Input and output functions

Abundant I/O interfaces: Equipped with various types of input/output (I/O) interfaces, including digital input (DI), digital output (DO), analogue input (AI) and analogue output (AO). The digital input interface can receive digital signals from switches, pushbuttons, proximity switches and other devices for detecting the state of the device (e.g. start/stop, on/off, etc.); the digital output interface is capable of outputting digital signals for controlling relays, indicators, solenoid valves, etc.; and the analogue input interface can receive analogue signals (e.g. 0 - 10V DC, 4 - 20m) from temperature sensors, pressure sensors, flow sensors and other devices. The analogue input interface can receive analogue signals from temperature sensors, pressure sensors, flow sensors and other devices (e.g. 0 - 10V DC, 4 - 20mA, etc.), which can be used to collect a variety of physical parameters in the industrial process; and the analogue output interface is able to output analogue signals for the control of devices that require continuous adjustment, such as frequency converters and control valves.

I/O Expansion Capability: I/O expansion interface is provided to allow users to flexibly add I/O expansion modules to increase the number of input/output points according to the complexity of the actual application scenario and the number of devices. This allows the system to be easily adapted to industrial automation projects of different scales, ranging from small single-machine equipment control to large-scale integrated control of production lines. For example, when more motors need to be controlled or more sensors need to be monitored, this can be easily accommodated by adding I/O expansion modules.

Communication Functions

Communication interface support: A variety of communication interfaces are available, such as Ethernet interface (RJ45), serial interface (RS-232, RS-485), etc. The Ethernet interface supports high-speed data transmission. The Ethernet interface supports high-speed data transmission and can be used for remote monitoring, communication with the host computer system and connection to the plant's local area network for centralised data management and remote control. Serial interface can be used to connect specific field devices or other devices with serial communication function for close communication, and in some strong electromagnetic interference environment, serial communication has better anti-interference ability.

Communication protocol compatibility: It supports a variety of industrial communication protocols, such as Modbus, Profibus, TCP/IP and so on. This makes it possible to communicate and exchange data with equipment produced by different manufacturers, which is convenient for users to integrate various brands of sensors, actuators and other automation equipment when building automation systems, and achieve a high degree of system integration and cooperative work. For example, in a factory automation system with both ABB and Siemens equipment, seamless communication can be achieved through these common protocols.

Technical Parameters

Electrical parameters

Operating voltage range: Typically has a wide operating voltage range, e.g. it can support common industrial supply voltages such as 18 - 30V DC or 85 - 264V AC, and can operate within a certain voltage fluctuation range (e.g. ±10% - ±15%). This ensures stable operation under different industrial site power conditions and reduces the risk of failure due to power fluctuations.

Power Consumption: Power consumption levels vary according to specific workloads and operating conditions, but are generally within reasonable limits to prevent the device from generating too much heat during long periods of operation, which could affect its stability and service life. Specific power consumption values can be found in the product manual for detailed descriptions.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923