K-WANG

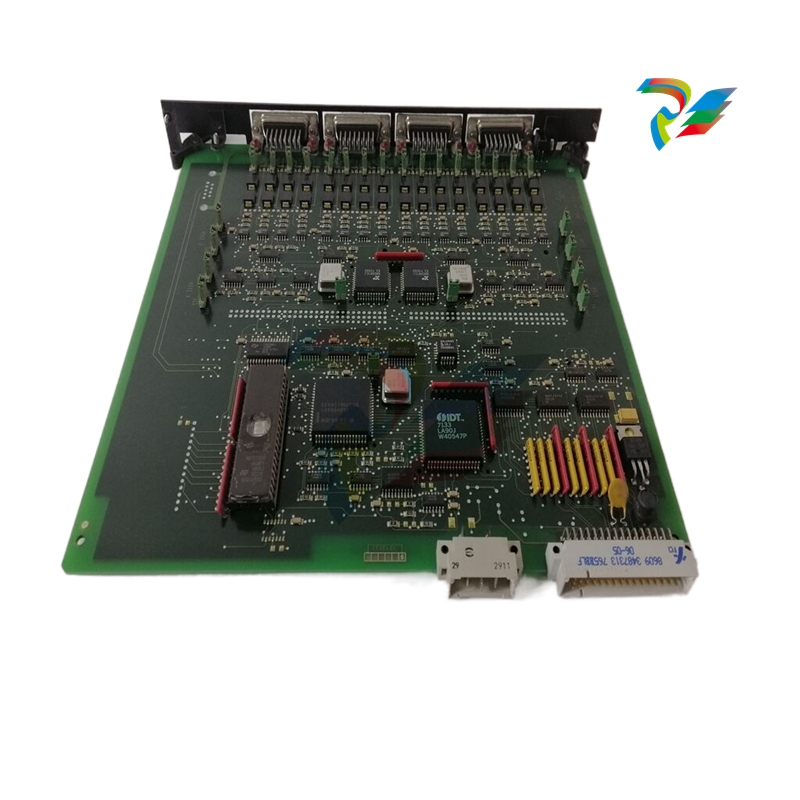

Alstom CK112 - Relay

The Alstom CK112 stands out as a highly reliable and efficient solution within Alstom’s extensive portfolio of automation and control products, specifically engineered for demanding environments such as the power industry, petrochemical plants, and general automation applications. Designed with advanced input/output (I/O) capacity, the CK112 supports high-speed data acquisition and processing, making it ideal for real-time control and monitoring tasks in critical industrial processes.

At its core, the Alstom CK112 offers versatile I/O configurations capable of handling both analog and digital signals with precision. Its robust architecture supports input voltages ranging from 24V to 110V DC, while output channels are designed to drive high-capacity loads with minimal latency. This ensures seamless integration with a wide array of field devices, including sensors, actuators, and control relays. The unit’s durability is enhanced by a ruggedized enclosure rated to withstand extreme temperatures, humidity, and vibration—conditions typical in petrochemical refineries and power generation facilities.

Performance-wise, the CK112 boasts a rapid response time, often clocking below 5 milliseconds for input-to-output signal processing, ensuring operators have near-instantaneous feedback and control. This responsiveness is critical in applications such as turbine control in power plants or safety interlocks in chemical processing units, where milliseconds can prevent costly downtime or hazardous incidents. The device also supports advanced diagnostics and self-monitoring functions, reducing maintenance overhead and increasing operational uptime.

In practical scenarios, the application of CK112 in the power industry is exemplary. It is frequently deployed in generator control systems, where its precise timing and robust signal handling optimize load sharing and fault detection. In petrochemical settings, the CK112’s ability to interface with safety shutdown systems enhances plant reliability and compliance with industry safety standards. For general automation, the CK112 integrates seamlessly into supervisory control and data acquisition (SCADA) networks, providing critical data streams and control outputs that maintain system stability and efficiency.

When compared to other Alstom models, the CK112 offers distinct advantages. While the Alstom SCN666 and Alstom SCN804 excel in communication and synchronization tasks, the CK112’s strength lies in its superior I/O capacity and ruggedness. Unlike the Alstom Micom P141 and Micom P743, which are primarily protection relays, the CK112 focuses on control versatility and precise signal management. Additionally, models such as the Alstom ALSPA MD2000 and Alstom Bitronics M870D provide monitoring and diagnostic capabilities but do not match the CK112’s comprehensive control functionality under harsh industrial conditions.

Alongside the Alstom CK112, complementary products such as the Alstom PIB201A and PIB651A-1500-3.3kV/L modules extend system capabilities by offering specialized power interfaces and voltage regulation essential for complex automation setups. The Alstom VTT Definitive Time Relay and Alstom CHECK SYNCHRONISING units provide critical timing and synchronization support, ensuring that the CK112 operates harmoniously within larger control networks. For mechanical and operational reliability, Alstom Timken/Torrington thrust bearings and Alstom Combustion Engineering Gasket Part # 62-278 add robustness to physical assemblies, indirectly enhancing the performance of automation components like the CK112.

The Alstom CK112 is a cornerstone within Alstom automation products, engineered to meet the stringent demands of modern industrial automation. Its application in the power industry, petrochemical, and general automation sectors underscores its versatility and reliability. By integrating the CK112 with complementary Alstom solutions such as the Alstom MVAA, Alstom RTS-61, and Alstom Carborne control systems, industrial operators can build sophisticated, scalable automation architectures that maximize efficiency, safety, and operational continuity.

In summary, the Alstom CK112 delivers unmatched performance through its high-capacity I/O handling, rapid response times, and industrial-grade durability. It excels in environments where reliability is paramount and rapid control actions are necessary. Whether deployed in power plants, chemical processing units, or automated manufacturing lines, the CK112 enhances system responsiveness and robustness, ensuring that Alstom’s reputation for quality and innovation continues to lead the market in advanced automation solutions.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923