K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Diagnosis control shows the status of the CI840 and node specific errors and warnings. Module specific diagnosis are displayed in the Diagnosis control for each I/O module.

ABB CI840 I/O module.

Figure 23. CI840 - Diagnosis - General Tab

Device state area

This text field shows the actual state of the FCI. Either the state is Operational or

the text field is left blank.

Device diagnostics area

The device specific errors that are detected for the CI840 are:

• Station warning

At least one error is detected within the entire CI840 station (including

I/O modules etc.).

• Redundancy warning

Decreased availability due to error on redundant part in the entire CI840

station.

In system with only single CI840 this warning could be raised if the system is

not correctly configured for single mode.

• Redundant power A failure

For the CI840 or an optical modem.

• Redundant power B failure

For the CI840 or an optical modem.

• CI840 in position A is primary

CI840 in position A is primary in a redundant pair also set if used as single.

• CI840 in position B is primary

CI840 in position B is primary in a redundant pair.

• CI840 error on unit in position A

CI840 in position A is erroneous.

• CI840 error on unit in position B

CI840 in position B is erroneous.

• Redundant cable A failed

The Profibus cable to CI840 in position A is unconnected or broken.

• Redundant cable B failed

The Profibus cable to CI840 in position B is unconnected or broken.

Station address warning

There is a mismatch between the actual address on the CI840 and the one

configured in the system or if the address is set above 62. The warning will be

cleared when the system is restarted with the right configuration or if the switch on

the CI840 is changed back to the configured address.

Configuration

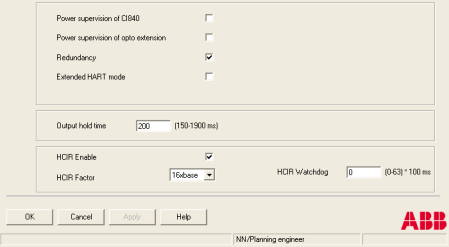

For configuration of the module, select the “Configuration” menu item. It shows the

user parameters for the FCI e.g. Output Hold Time.

This control is not available if the unit is used towards AC 800M. The

configuration data is then set via Control Builder Professional

Figure 24. CI840 - Configuration for AC870P

Sequence of Events

The Sequence of Events checkbox determines the status of the SOE feature in the

supported I/O modules:

• If this checkbox is checked, the SOE drop-down menu in the Channel

Parameters tab of the supported I/O modules is activated. The user can then

select the SOE status for each channel.

• If this checkbox is unchecked, the SOE is disabled for the supported modules,

and the SOE drop-down menu in the Channel Parameters tab of the supported

modules is not activated.

SOE is supported in DI825. DI830. DI831. and DI885 modules.

Power supervision of FCI

Mark the check box if the voltage supply to the FCI shall be supervised. Only if

redundant power supply.

• Power supervision of opto extension

Mark the check box if the voltage supply to the cluster shall be supervised.

Only if redundant power supply.

• Redundancy

Mark the check box if the CI840 shall be configured as a redundant module.

• Extended HART mode

Normal mode shall always be used if HART data is < 56 bytes. Mark the check

box if the HART data is > 56 bytes but < 215 bytes. If Extended HART mode

is chosen less I/O modules can be used. See Memory Maps for more details.

• Output hold time

After a fail over, a timer is started in the new primary CI840. This CI840

requires configuration and data from the Profibus Master within the output

hold time, which is defined in the Output hold time text field. If no data is

received within the defined time, the channels on the output modules are set to

the predefined value (OSP value).

• HCIR Enable

Hot Configuration In Run active

• HCIR Factor

Hot Configuration In Run Factor

• HCIR Watchdog

Hot configuration In Run Worst Case Bus Cycle Base

Configuration Control of DI825/DI830/DI831/DI885 with CI840 for SOE

To use the modules DI825/DI830/DI831/DI885 for SOE, open the

ServiceEntries.xml file, and set the value of the ‘EnableSOE’ attribute to 1.

The location of ServiceEntries.xml is

default.

Table 3 describes the different configuration control options for the SOE supported

modules DI825. DI830/DI831 and DI885. used with CI840 for AC870P.

It is assumed that the EnableSOE attribute is set to 1 globally.

Table 3. Configuration control of SOE supported modules used with CI840. for

AC870P

Status of ‘Sequence of

Events’ checkbox in

CI840 Configuration

Control

Displayed status in the

‘SOE’ drop-down menu in

DI825/DI830/DI835/DI885

Configuration Control

Whether the displayed

SOE status in DI8xx

can be changed

Unchecked, by default,

after inserting the CI840

for the first time

SOE disable No

Checked after an

unchecked status

SOE disable Yes

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923