K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

EMERSON FX-316 drives

EMERSON FX-316 drives

DESCRIPTION

The motion control solution consists of three essential pieces that form the basic system. The components are an FX Positioning Drive, DX Series Brushless Servo Motor and motor cabling. This basic system can be enhanced with the addition of snap-on application modules or peripheral equipment.

FX Amplifiers and DX Motors

The FX drives are capable of driving motors with torque ratings from 8 to 400 lb-in (pounds per inch) continuous output and speeds to 5000 RPM (revolutions per minute).

DX motors are available in sizes that match each of the FX amplifiers’ power output. Many of the motors are available in metric or English flange and shaft combinations. A holding brake is also available with most DX motors.

Most models are available with two standard styles of electrical connections. The first style has “MS” (Military Specification) connectors; the second style has internal terminal strips. Pre-assembled cables for resolver feedback and stator wiring are available for DX motors ordered with MS style connectors. DX motors without MS style connectors meet IP65 waterproofing standards for operation in a wash-down environment. Pre-assembled cables for resolver feedback are also available for DX motors without MS style connectors.

Resolver Cables

Pre-assembled resolver cables that connect the low voltage resolver and motor thermostat signals from the DX motor to the FX amplifier are available in three standard lengths: 15, 25 and 50 feet (100 feet is the maximum cable length allowed without EMERSON Motion Control factory approval.) There are two styles of resolver cables available for DX motors (RC-XXX and ECF-XXX). The RC-XXX cable is used for motors without MS connectors and the ECF-XXX cable is used for motors with MS connectors

Stator Cables

For DX motors with MS style connectors a stator cable for the three motor phases and ground wires and the optional brake is available in three standard lengths: 15, 25 and 50 feet. For DX motors without MS style connectors, the stator wiring for the three motor phases and ground wires and the optional brake can be ordered from EMERSON Motion Control or can be supplied by the user.

A summary of the available features is shown below.

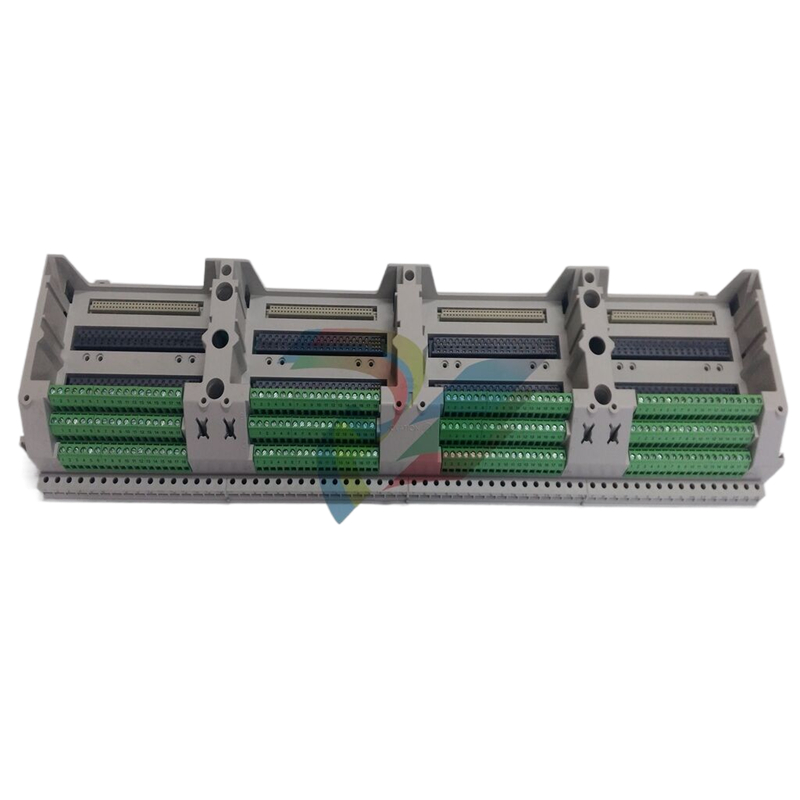

• Expanded I/O: IOM-1 and all application modules. Twelve additional I/O lines (eight input and four output) provide additional I/O capacity.

• Memory Expansion: All application modules except IOM-1. Memory to support complex programming and storage.

• Programs: All application modules except IOM-1. Programs allow you to link Indexes and other functions together for more complex moves.

• Parallel Interface: IOM-1 and PCM-1, 2 and 4. The parallel interface feature allows the use of thumbwheels and T-16 numeric displays for programming and drive information.

• Ratio Control: PCM-15, 16, 17, 18, 19, 22, 23, 24 and IBS-15. Ratio Control permits the FX drive to synchronize motion with an external encoder or another FX drive/PCM module combination. A 25 pin socket is provided for connection to an encoder cable. A through connector allows multiple axes to be synchronized to an external encoder or to each other.

• Suspend/Resume: All application modules except IOM-1. Suspend/ Resume allows you to suspend the motion in progress, move the machine to a position not within that program, perform other operations and then return and complete the remainder of the original program.

• Web Loop Control: PCM-18 only. Loop control is used in web control applications to achieve constant web speed when the take-up roll or unwind roll is center wound by an FX drive.

• Press Feed: PCM-24 only. The PCM-24 provides sophisticated control of a press feed application with minimal operator programming experience. The PCM-24 synchronizes the feed to the press cycle using a master synchronization encoder which tracks the position of a press

• Cam Profiler: PCM-23 only. Electronically simulates a mechanical Cam.

• Flying Cutoff: PCM-14, 15 and 24. Flying cutoff provides accurate length cuts for almost any process.

• Slip Compensation: PCM-14 and 24. Automatically compensates for product slip to maintain precise positioning

Our Main Brands

· - ABB Advant-800xA,Advant OCS,Bailey Infi 90 and Net 90,H&B Freelance 2000,DSQC Robots,IGCT / IGBT

· - GE General Electric Field Control, Genius I/O, QuickPanel, RX3i PacSystem, Series 90, Series 90, Series VersaMax

· - Allen Bradley Allen-Bradley SLC500, MicroLogix, CompactLogix, ControlLogix, PLC-5, Panel View,

· - Bently Nevada 3300 System, 3500 System

· - Honeywell 7800 Series, FSC, IPC, Mxopen, TDC 2000, TDC 3000, Experion PKS(C200,C300)

· - Yokogawa Centum CS - Centum VP, Centum XL - micro XL, FA-M3, ProSafe-PLC

- Ovation, Foxboro, EPRO, Emerson DeltaV, Fuji, Siemens, HIMA, Prosoft, Invensys Triconex, ICS TRIPLEX, Woodward, Bachmann, Schneider

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923