K-WANG

GE DL-1200/RTU - Remote Terminal Unit for Industrial Automation

The GE DL-1200/RTU stands out as a robust and highly versatile remote terminal unit (RTU) designed to meet the demanding requirements of modern automation systems across various industries. Engineered with advanced technology and proven reliability, the DL-1200/RTU offers exceptional input/output capacity, durability, and performance metrics that make it an indispensable component in power, petrochemical, and general automation applications.

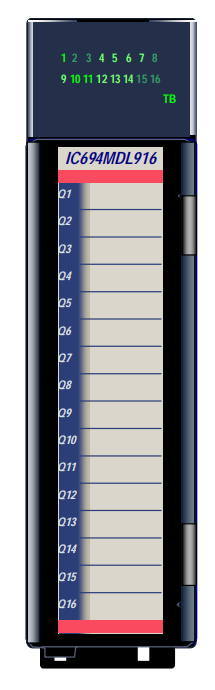

One of the key technical features of the GE DL-1200/RTU is its extensive I/O capability, supporting a wide range of analog and digital signals that facilitate seamless data acquisition and control in complex automation environments. Its rugged construction ensures high durability, capable of operating reliably in harsh conditions such as extreme temperatures, vibration, and electrical noise common in industrial settings. The RTU's high-speed processing enables real-time data communication, essential for critical applications like grid management, remote monitoring of petrochemical processes, and automation in heavy industries. Additionally, the DL-1200/RTU boasts a modular design that simplifies installation and maintenance, reducing downtime and operational costs.

In real-world scenarios, the GE DL-1200/RTU excels in power industry settings, where it manages remote substations, monitors grid stability, and facilitates SCADA integration with high precision. Its robustness ensures continuous operation in remote locations with limited maintenance access. Within petrochemical plants, it efficiently oversees complex control systems, ensuring safety and operational efficiency under challenging environments. In general automation, it supports factory floor automation, building management systems, and infrastructure monitoring, demonstrating its flexibility and adaptability across sectors.

Compared to other models within the GE automation product family, the DL-1200/RTU offers notable advantages. For instance, while models like GE IC200MDL240 or GE IS200WEORG1ACDB provide similar control functionalities, the DL-1200/RTU's higher I/O capacity and enhanced environmental resilience give it an edge in large-scale, demanding applications. Its compatibility with a broad range of communication protocols ensures integration with existing systems, making it a future-proof choice. Furthermore, when compared to models like GE IC660TBA024 or GE IC695HSC304, the DL-1200/RTU’s streamlined architecture simplifies deployment and scaling in complex automation networks.

Alongside the GE DL-1200/RTU, we also offer complementary models such as the GE IS200WEORG1ACDB and GE IC3600SIXJ1A1A, which provide specialized control and interface functions that enhance overall system performance. For instance, the GE IS200EDCFG1AED and GE IS210AEAAH1BKE are ideal for signal conversion and interface management, ensuring seamless integration across different automation layers. The GE IC200ALG620 and GE IC200MDL734D expand the control portfolio, supporting advanced automation tasks with high reliability. Other models like the GE DS200DCFBG1BGB and GE IC600CB527M address specific control and communication needs, providing a comprehensive suite of solutions tailored to diverse operational scenarios.

The application of DL-1200/RTU in power industry, petrochemical, and general automation underscores its versatility and reliability as a core component of GE’s automation products. Its ability to handle large I/O volumes, operate reliably in adverse conditions, and integrate effortlessly with other control and communication modules make it an ideal choice for expanding automation infrastructure. Whether managing remote substations, overseeing chemical processing, or automating manufacturing processes, the GE DL-1200/RTU delivers superior performance and peace of mind.

In summary, the GE DL-1200/RTU exemplifies the pinnacle of GE automation products, combining high I/O capacity, durability, and flexible integration. Its unmatched performance in critical industrial environments, along with the support of a broad ecosystem of compatible models, ensures that it remains a preferred solution for automation professionals seeking reliable, scalable, and efficient remote terminal units.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923