K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

Input 24 VDC; Output 24 VDC/0.5A,

Estimated Shipping Size

Dimensions: 6.0" x 4.0" x 5.0"

(15.2 cm x 10.2 cm x 12.7 cm)

Weight: 0 lbs 12.0 oz (0.3kg )

Tariff Code: 8538907080

Country of Origin: Germany

Ships from Webster NY, USA

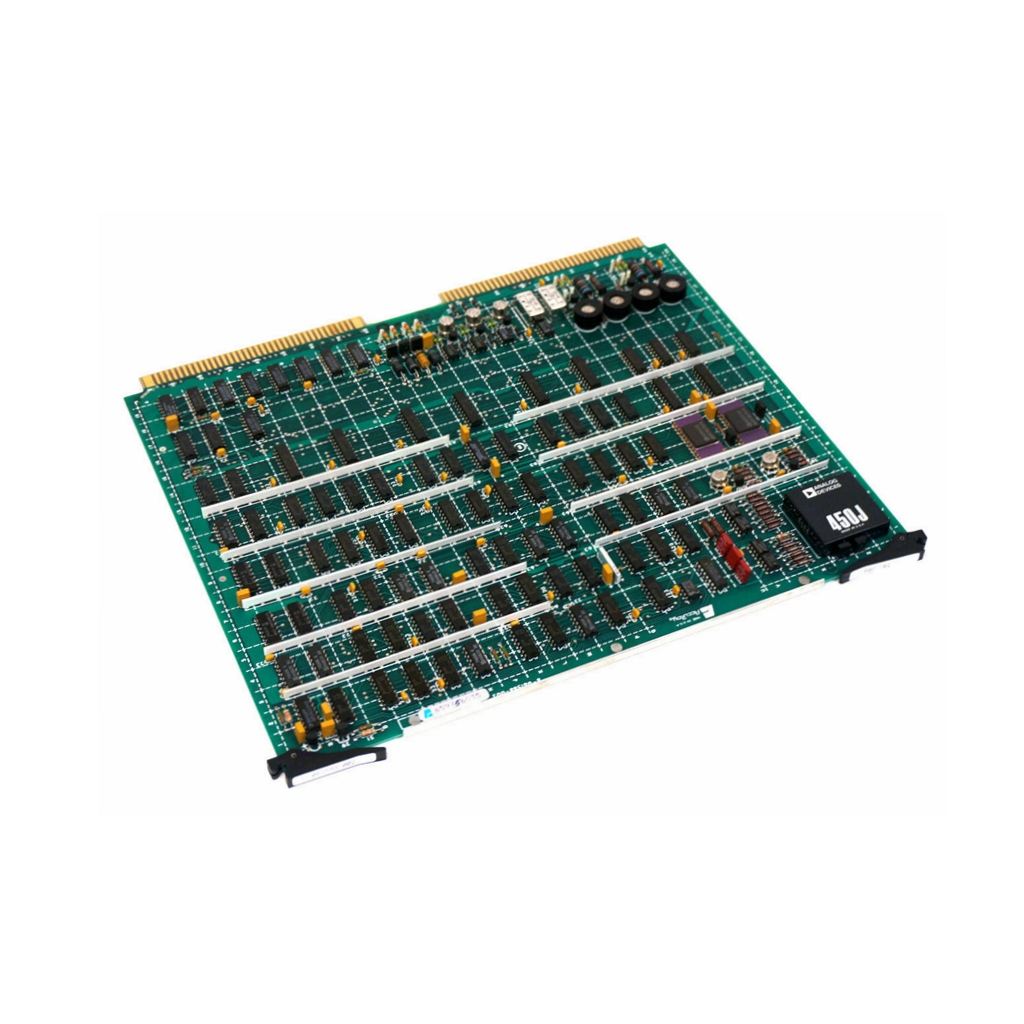

ABB GJR5251400R0202 Advant Controller 31 I/O Unit

Basic Information

Model specification: ABB GJR5251400R0202 Advant Controller 31 I/O Unit is an input/output (I/O) unit designed specifically for ABB's Advant Controller 31 system. It plays a key role in connecting the controller to external devices throughout the automation control system, and the combination of numbers and letters in the model number represents its specific function and configuration information.

Country of origin: This product is originally from Sweden. Sweden is one of ABB's key production sites, where a state-of-the-art manufacturing environment and strict quality control systems ensure high quality.

Physical Characteristics: Although no specific data is provided on dimensions and weight, this type of I/O unit is generally designed to be compact and easy to install in control cabinets. Its size is usually as small and light as possible, taking into account the limited space available in the industrial site, while at the same time ensuring good heat dissipation and electrical isolation.

Availability: There are certain supply channels in the market and some professional automation equipment suppliers will have stocks. Its supply situation may be affected by the production cycle, market demand and other factors, but as ABB's mainstream products, under normal circumstances can be obtained through regular channels.

Functional characteristics

Signal Processing Functions

Multiple signal type compatibility: capable of handling multiple types of input and output signals. For input signals, it can receive digital signals, such as switching signals from limit switches, proximity switches and other devices, which can indicate the positional status of the device, operating status and other information; it can also receive analogue signals, like continuously changing voltage or current signals from temperature sensors and pressure sensors, which can be used to monitor changes in physical quantities at the site. In terms of output, it can output digital signals to control the on-off of relays, contactors and other devices to achieve start-stop control of motors, valves and other actuators; it can also output analogue signals, such as control valves, inverters and other devices for precise opening or frequency control.

High-precision signal conversion: It has high-precision signal conversion capability in the processing of analogue signals. When receiving analogue input signals, it can accurately convert the weak voltage or current signals coming from sensors into digital signals for processing by the controller. For example, for a 0 - 10V analogue input signal, it can accurately quantify it into the corresponding digital value with a conversion accuracy of 12 - 16 bits, which means that changes in on-site physical quantities can be more finely reflected. In the case of analogue outputs, digital signals can also be accurately converted to analogue signals according to the controller's commands, delivering a stable voltage or current and ensuring that the actuator works as intended.

Configuration Flexibility

Customisable I/O channel configuration: Flexible I/O channel configuration options are provided. Users can customise the number and type of digital inputs, digital outputs, analogue inputs and analogue output channels according to the actual application requirements through software configuration or hardware jumpers. For example, in a simple temperature control system, users can configure more analogue input channels for connecting multiple temperature sensors, and at the same time configure an appropriate number of digital output channels to control the start and stop of heating or cooling equipment; while in a complex automated production line control application, I/O channels can be flexibly allocated according to the signal types and number requirements of different devices to achieve efficient control of the entire production line. Compatibility with the system

Compatibility Configuration with System: It has good compatibility with Advant Controller 31 system and can be seamlessly integrated into the whole control system. It can communicate with the controller through the standard communication interface and supports a variety of communication protocols, such as Profibus - DP, CANopen, etc., ensuring fast and accurate data transmission. Moreover, it can easily work with other I/O units, controllers, human-machine interfaces (HMIs) and other devices according to the system architecture and control strategy to build a complete automation solution together.

Operation Reliability

Strong anti-interference ability: In the industrial environment, there are a large number of electromagnetic interference sources, such as electromagnetic radiation generated by motors, frequency converters and other equipment. The I/O unit adopts effective electromagnetic shielding technology and filtering measures to resist these external disturbances and ensure signal integrity and accuracy. For example, its internal circuit layout has been carefully designed to shield sensitive signal lines, while a filter circuit has been set up at the input and output interfaces to effectively filter out high-frequency interfering signals, so that the unit can still work stably in a complex electromagnetic environment.

Fault diagnosis and protection function: It has a fault diagnosis function, which can monitor its own working status and the signal status of I/O channels in real time. When there is a signal abnormality, channel failure, power failure, etc., it can send fault alarm information to the controller in time, and at the same time take corresponding protection measures, such as automatically cutting off the output of the faulty channel to prevent the expansion of the fault. This fault diagnosis and protection mechanism helps to improve the reliability and safety of the whole system and reduce the downtime caused by equipment failure.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923