K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

The 4 Amp 16 Point Relay Output module provides 16 Form A relays for controlling

output loads. The maximum output switching capacity of each circuit is 4 Amps. Each

output point is isolated from the other points, and each point has a separate common

power output terminal. Outputs provide a high degree of noise immunity, minimizing

the need to add external snubbers. The relay outputs can control a wide range of

output devices, such as: motor starters, solenoids, and indicators. The user must

supply the AC or DC power to operate the field devices.

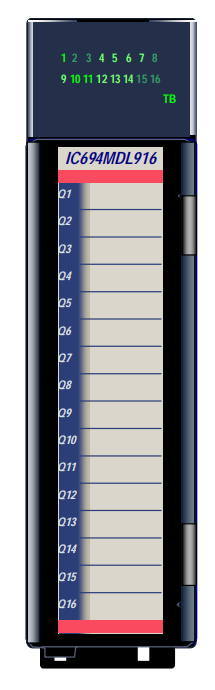

GE IC694MDL916 Output Module, Isolated Relay

The 4 Amp 16 Point Relay Output module provides 16 Form A relays for controlling

output loads. The maximum output switching capacity of each circuit is 4 Amps. Each

output point is isolated from the other points, and each point has a separate common

power output terminal. Outputs provide a high degree of noise immunity, minimizing

the need to add external snubbers. The relay outputs can control a wide range of

output devices, such as: motor starters, solenoids, and indicators. The user must

supply the AC or DC power to operate the field devices.

This module is available as a PACSystems RX3i module (catalog number

IC694MDL916), illustrated at left, or as a Series 90-30 PLC module (catalog number

IC693MDL916). The RX3i version is only compatible with a PACSystems RX3i CPU.

The Series 90-30 version can be installed in any I/O slot in a PACSystems RX3i or

Series 90-30 PLC. See the next page for details of specific CPU version requirements.

Module MDL916 can be used with a Box-style (IC694TBB032), Extended Box-style

(IC694TBB132), Spring-style (IC694TBS032), or Extended Spring-style

(IC694TBS132) Terminal Block. Extended terminal blocks provide the extra shroud

depth typically needed for shielded wires. See the PACSystems RX3i System Manual,

GFK-2314 revision B or later for more information about terminal blocks. Terminal

Blocks are ordered separately.

A DIP switch on back of the module is used to select the outputs’ default mode: Force

Off or Hold Last State. The module must be removed from the backplane to set this

switch.

Individually-numbered LEDs indicate the ON/OFF state of each output. The red/green

TB LED is green when the module’s removable terminal block is locked in place. It is

red when the terminal block is not locked.

Module IC694MDL916 reports Addition of Terminal Block, Loss of Terminal Block,

Hold Last State Configuration Mismatch, and Module Over Temp messages to the

RX3i CPU. Module IC693MDL916 does not report diagnostic status to the CPU.

The red bands on the door card show that MDL916 is a high-voltage module.

Release Information

Release History

Release Comments

IC693MDL916-AA, IC694MDL916-AA Initial Release

Functional Compatibility

Compatible CPU Versions

Module Configuration Software PACSystems

RX3i Series 90-30

IC693MDL916 CPU350 - 10.60, CPU352 - 10.50,

CPU364 – 10.60, CPU374 - 11.03

IC694MDL916

Proficy Machine Edition

version 5.5,

Service Pack 2 or later

Firmware version

3.81

Not compatible

Installation in Hazardous Locations

• EQUIPMENT LABELED WITH REFERENCE TO CLASS I, GROUPS A, B, C & D, DIV. 2 HAZARDOUS

LOCATIONS IS SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C, D OR NON-HAZARDOUS

LOCATIONS ONLY

• WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIVISION 2;

• WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES; AND

• WARNING - EXPLOSION HAZARD - DO NOT CONNECT OR DISCONNECT EQUIPMENT UNLESS POWER

HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE NONHAZARDOUS.

Specifications

Refer to the PACSystems RX3i System Manual, GFK-2314, for product standards and general specifications.

Outputs per Module 16 isolated Form A relay outputs

External Power Supply 0 – 125VDC (5/24/125 VDC nominal)

0 – 250VAC (47 to 63 Hz), 120-240VAC nominal

Isolation

Field to Backplane and

to Frame Ground,

Group to Group

250 VAC continuous; 1500 VAC for 1 minute.

Power Consumption 300mA at 5VDC from backplane maximum (all outputs ON)

Thermal Derating See next page

Output Characteristics

Output Voltage 5 – 125VDC (5/24/125 VDC nominal)

5 – 250VAC (47 to 63 Hz), 120-240VAC nominal

Output Current 10mA per point minimum

4A for 5-250VAC maximum (resistive or general purpose)

4A for 5-30VDC maximum (resistive)

200mA for 125VDC (maximum resistive)

2A pilot duty per output (5 to 30VDC, 5 to 250VAC)

2A lamp load per output (5 to 30VDC, 5 to 250VAC)

Output Voltage Drop 0.3VDC maximum

Output Leakage Current Not Applicable (open contact)

Response Times (On/Off) 10ms maximum (At nominal voltage excluding contact bounce)

Switching Frequency 20 cycles per minute maximum

Protection None. External snubbers may be applied if necessary

Relay Contact Life See chart on the next page

Diagnostic Information Field side terminal block presence detection reported to CPU (for RX3i

only)

* When this module is used with DC power supply IC695PSD040 or PSD140, special precautions should be taken

because dropouts in the source voltage will be seen by this module and may cause relay dropouts.

Thermal Derating

The table below shows the number of outputs that can be on at the same time under the maximum load of 4

Amps per point.

Load Current Limitations

Operating Maximum Current for Load Type Typical Contact Life

Voltage Resistive Lamp or Solenoid * (Number of Operations)

5 to 250 VAC 4 Amps 2 Amps 200,000

5 to 250 VAC 0.1 Amp 0.05 Amp 1,000,000

5 to 250 VAC 1 Amp 0.5 Amp 700,000

5 to 30 VDC 4 Amps 2 Amps 200,000

5 to 30 VDC 1 Amp 0.5 Amp 700,000

5 to 30 VDC 0.1 Amp 0.05 Amp 1,000,000

* Assumes a 7ms L/R time constant (DC inductive load) or Cos φ > 0.4 (AC inductive load)

Setting the Output Defaults

The DIP switch on back of the module determines how the outputs will operate if the CPU is set to Stop Mode or

loses communications with the module. The Outputs Default Mode selection made with the DIP switch must

match the selection made for this feature in the module’s software configuration. If the two do not match, a

warning message is displayed in the fault table.

The module must be removed from the backplane to set this switch. Note that there are two DIP switches on the

module. Only the upper switch is used.

Outputs Default mode DIP Switch

Closed (left) = Hold Last State

Open (right) = Force Off

Not Used

With the Outputs Default Mode switch in the right

(open) position, the outputs will turn off whenever

communication with the CPU is lost.

When the switch is in the left position, the outputs

will hold their last programmed value whenever

communication with the CPU is lost. Backplane

power must be present to Hold Last State.

Otherwise, the module will default outputs

regardless of the DIP switch setting.

Field Wiring: MDL916

Connections Terminals Terminals Connections

Output 1, Normally-Open 1 19 Output 9, Normally-Open

Output 1 Return 2 20 Output 9 Return

Output 2, Normally-Open 3 21 Output 10, Normally-Open

Output 2 Return 4 22 Output 10 Return

Output 3, Normally-Open 5 23 Output 11, Normally-Open

Output 3 Return 6 24 Output 11 Return

Output 4, Normally-Open 7 25 Output 12, Normally-Open

Output 4 Return 8 26 Output 12 Return

Output 5, Normally-Open 9 27 Output 13, Normally-Open

Output 5 Return 10 28 Output 13 Return

Output 6, Normally-Open 11 29 Output 14, Normally-Open

Output 6 Return 12 30 Output 14 Return

No Connection 13 31 No Connection

Output 7, Normally-Open 14 32 Output 15, Normally-Open

Output 7 Return 15 33 Output 15 Return

No Connection 16 34 No Connection

Output 8, Normally-Open 17 35 Output 16, Normally-Open

Output 8 Return 18 36 Output 16 Return

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923