K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

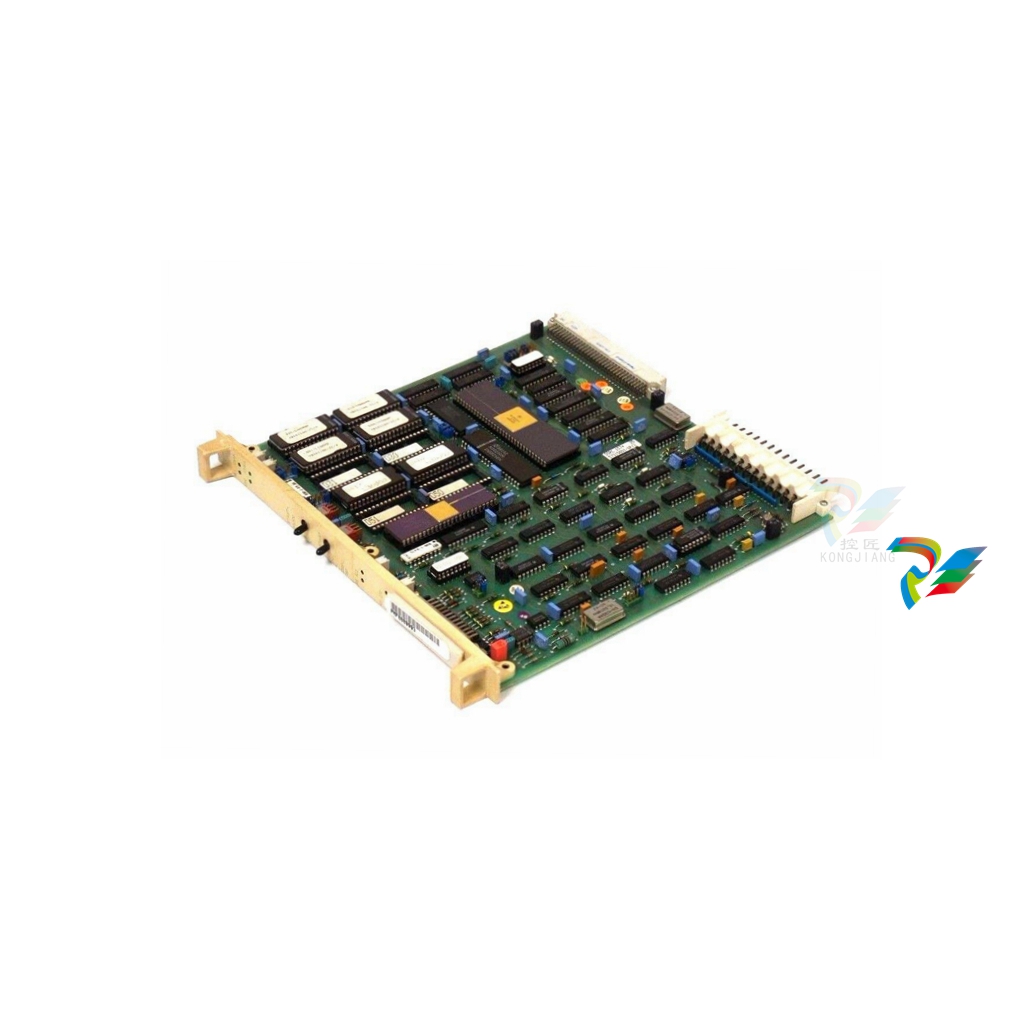

ABB POT 01 Operator Keypad POT 01 H&B Contronic

Basic introduction

ABB POT 01 Operator Keypad POT 01 H&B Contronic is an operator keypad designed for H&B Contronic systems. It is used to facilitate operator input into the system and is an important component for human-computer interaction.

Functional features

Convenience of operation

Compact and rational layout: The keypad layout is compact and integrates the key buttons required for system operation in a limited space. It usually contains numeric keys (0 - 9) for numeric value input, and function keys such as confirm, cancel, page up/down, left/right movement, etc. The layout of these keys is ergonomic, which makes it easy for the operator to find and operate them quickly and reduces the operation time.

Good tactile feeling of the keys: The design of the keys takes into account the tactile experience, with appropriate elasticity and feedback strength. When pressing the keys, the operator can clearly feel the response of the keys to ensure the accuracy of the operation. This sense of touch is comfortable for the user in both frequent operation and occasional use.

System compatibility

Seamless integration with the system: The keypad is customized for the H&B Contronic system, enabling seamless integration with the system. It accurately transmits commands entered by the operator via keystrokes to the system and follows the system's communication protocols to ensure that the commands are executed correctly. For example, when a parameter adjustment command for a device is entered, the system receives and processes the command as expected.

Adaptation to multiple system functions: It is possible to adapt the operation of the H&B Contronic system to a wide range of functions. Whether it is simple control of the device (e.g. start, stop) or complex parameterization and data entry, the keypad can be used. It acts as a universal input tool, providing easy access to the system's various operations.

Durability and Reliability

Ruggedized construction: Ruggedized materials are used to manufacture the housing and keypad to withstand the physical impact and wear and tear of an industrial environment. In industrial sites, equipment may be subjected to collisions, vibrations, dust and liquids, and the keypad is able to work stably for a long time in such environments. For example, its housing can effectively prevent a certain degree of collision damage to the internal circuitry, and the keys are not easily damaged by frequent pressing.

Stable signal transmission: It is highly stable in signal transmission. It is connected to the system through reliable interfaces and communication lines, which can effectively avoid signal loss, interference or incorrect transmission. Even in industrial environments with strong electromagnetic interference, such as workshops with a large number of motors, inverters and other equipment, it can still ensure accurate signal transmission, so that the operating instructions can reach the system reliably.

Technical Parameters

Key information

Number of buttons: generally contains more than ten to twenty buttons, the specific number depends on the functional design. In addition to the basic numeric and function keys, there may be some customized function keys to meet specific system operating requirements.

Key type: Mechanical keys or membrane keys. Mechanical keys have a better tactile feel and a longer service life, making them suitable for frequent operation; membrane keys are more compact, preventing dust and liquids from entering and providing a better seal.

Interface type

Interface: Standard industrial interfaces, such as RS-232, USB or RS-485, are usually used. These interfaces are convenient to connect with the system host or other control devices, and have good versatility and compatibility, support for hot-swap operation, easy installation and maintenance of equipment.

Communication rate: The data transmission rate of the interface can meet the real-time operation requirements of the system, generally between 9600bps - 115200bps, to ensure that the commands of key operation can be transmitted to the system in a timely and accurate manner.

Working environment parameters

Temperature range: it can work normally in a wide temperature range, such as - 10℃ - +50℃, so that it can adapt to different industrial site temperature conditions, whether in the cold outdoor equipment control environment or in the warm indoor workshop environment.

Humidity range: the relative humidity range is generally between 10% - 90% (non-condensing), can work stably under a certain humidity conditions, to avoid damage to electronic components or performance degradation caused by humidity problems.

Application Scenarios

Industrial automated production line

Equipment control and parameter input: In the automated production line, it is used to control the running status of the equipment, such as starting and stopping a certain part of the production line equipment, and also used to input the running parameters of the equipment. For example, in the food packaging production line, the keypad can be used to control the start and stop of the packaging machine, and also to input parameters such as packaging speed and packaging quantity.

Troubleshooting and Maintenance: When equipment failure occurs, the operator can query the fault code through the keypad, enter the maintenance instructions or restore the initial settings of the equipment, which is convenient for quick troubleshooting and restoring the normal operation of the production line.

Process control system

Parameter Adjustment and Monitoring Aid: It is used as an auxiliary tool for parameter adjustment and system monitoring in process control system of chemical industry, electric power, water treatment and so on. The operator can input the set values of process parameters, such as temperature, pressure, flow rate and other control parameters through the keypad, and at the same time, he can also view the real-time operation data and alarm information of the system for timely adjustment and processing.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923