K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

ABB H&B Contronic RK 01 Module RK 01 H&B Contronic

Functional Features

Signal processing function: It can collect and process signals from a variety of industrial sites, including analog and digital signals. It can receive analog input signals from various types of sensors, such as temperature, pressure, flow and other sensor signals, and convert them into digital signals for use in the control system. For digital signals, such as switching signals, pulse signals, etc., can be accurately identified and processed, can be used for equipment status monitoring and counting and other functions.

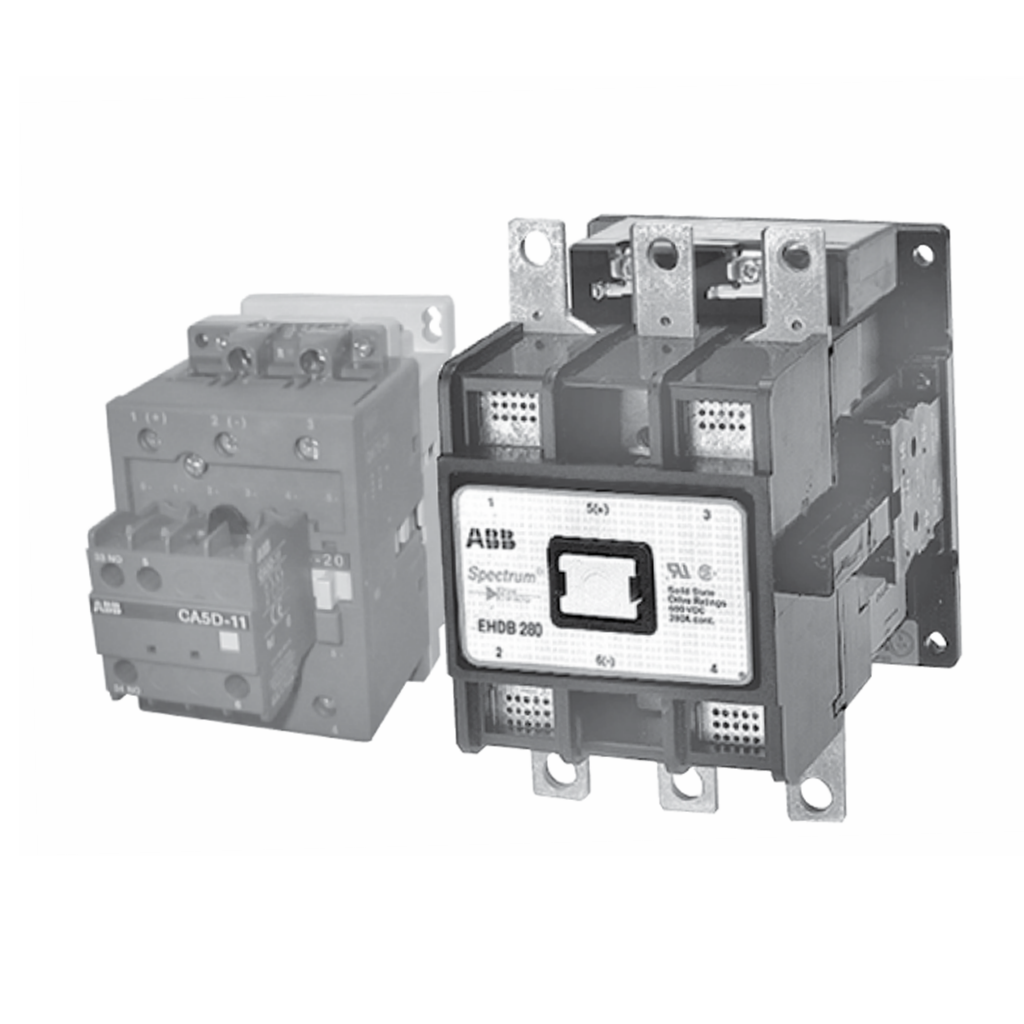

Control function: with certain output control capability, it can output digital signals or analog signals to control external devices, such as relays, contactors, regulating valves, inverters, etc., so as to realize the control of motors, valves, fans and other devices in the process of industrial production, and to ensure the normal operation of the production process.

Communication function: support communication with other devices, may use common industrial communication protocols, such as Profibus-DP, Modbus, etc., to facilitate data exchange and collaborative work with PLC, host computer, human-machine interface and other devices, to achieve centralized monitoring and management of the entire automation system.

Technical Parameters

Power supply voltage: 24V DC is usually used to supply power, which can work stably within a certain voltage fluctuation range to ensure the normal operation of the module.

Signal input and output range: analog input signal range may include 0-10V voltage signal, 4-20mA current signal, etc.; analog output signal range is generally 0-10V or 4-20mA; the number of digital input and output channels depends on the specific model, which can meet the needs of different application scenarios.

Communication interface: It is equipped with corresponding communication interface, such as RJ45 interface for Ethernet communication or DB9 interface for serial communication, etc. It supports various communication protocols, and the communication rate varies according to the protocols adopted and specific application scenarios.

Application Areas

Industrial automated production line: widely used in automated production lines in automotive manufacturing, machining, food and beverage, pharmaceutical and other industries, it can realize the monitoring and control of production equipment, such as the control and status monitoring of motors, conveyor belts, packaging machines, and other equipment on the production line, to ensure that the production line operates efficiently and stably.

Energy Management System: In power plants, substations, solar power stations, wind farms and other energy facilities, it can be used to collect and process various parameters in the process of energy production and transmission, such as voltage, current, power, etc., and to realize the control and management of power generation equipment, transmission equipment, etc., to improve the efficiency of energy utilization and the stability of the system.

Intelligent building automation system: in the HVAC system, lighting system, water supply and drainage system, etc. of intelligent buildings, it can be used to control and monitor the operation status and environmental parameters of the

APPLICATIONS

• Simulation

• Instrumentation

• Industrial control

• Process control and monitoring

• Factory automation

• Intelligent networked PLC controllers

• Automated test

• Data acquisition

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923