K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

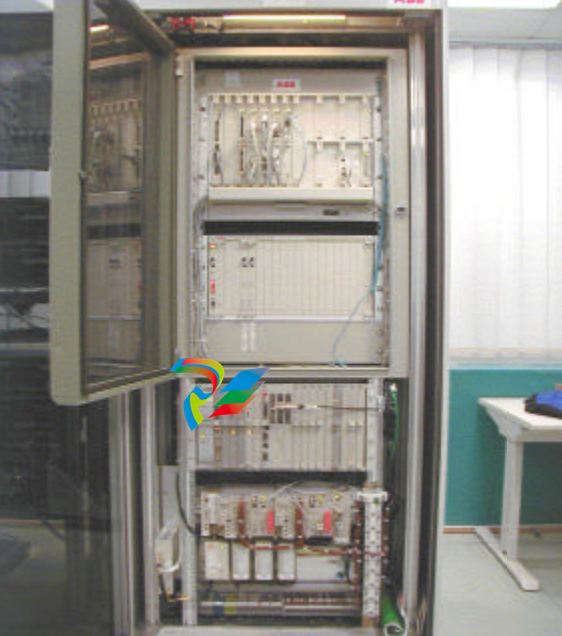

The central control station has been fully equipped with ABB Advant OCS control hardware.

ABB-CI546-Conveyor Control

The central control station has been fully equipped with ABB Advant OCS control hardware. A fast and secure transmission protocol couples to the AC450 Advant controllers in the central station the many decentralised components of other manufacturers that control the mining machines and conveyor lines. Serial interfaces such as MODBUS could not be used because of the large amount of data to be transmitted. The standardised Ethernet infrastructure proved to be the only applicable network solution. The Transmission Control Protocol / Internet Protocol (TCP/IP) was chosen for transmission. That protocol has been used so far mainly in LAN and WAN but is getting applied more and more for transmission purposes as well.

The Central Control Station at Jaenschwalde, Germany ABB, Open-pit mining, Cottbus/Germany 4 2.1 Communication Infrastructure Four OTN (Open Transport Network) loops serve as data connections between the central control station and the individual technological lines. Loop 1 pit Loop 2 overland connection of the F60 overburden bridge Loop 3 Cottbus North Loop 4 pre-cut Thanks to those redundant optical-fibre loops and the OTN nodes it is possible to transmit the signals of the individual bus systems and video signals to the central control station.

The Central Control Station at Jaenschwalde, Germany ABB, Open-pit mining, Cottbus/Germany 5 2.2 Communication Infrastructure of the Central Control Station As regards connections of control station components, it is necessary to distinguish the equipment bus and the process network (PLAN) from the local area network (LAN). The equipment bus is an MB300 master bus system which has been made redundant with a view to higher availability. Participants are connected via two star couplers (for redundancy), executed in 19-inch technology. Participants are the active components of the “Advant” control system, such as operator stations, information management stations and computers. The exchange of information between all subordinate units is made on Ethernet basis via TCP/IP by twisted-pair cable (category 5). Those units, such as servers and client PCs are divided into sub-networks according to tasks and security aspects. 3. Conveyor Control The CI546 multi-vendor interface of ABB supports TCP/IP and UDP and has therefore been chosen for coupling the entire coal and pre-cut conveyor system with the AC450. The drive stations of the coal conveyor line are equipped with A800 controllers, those of the pre-cut conveyor line with remote-field controllers (RFC). The connection with the A800 head-station control is made by a WIN 3.11 IPC integrated into the system that on its part exchanges data with the PLC system via a dual-port RAM.

Zentralleitstand im Tagebau Jänschwalde ABB - Fördertechnik, Cottbus/Germany 7 The gateway PC behaves like a fully transparent protocol converter. The Ethernet network is connected to the gateway CPC by the OTN communication network. The distances to be bridged are up to 12 kilometres. For the pre-cut conveyor line 2000 integer words are passed on in the reception protocol and 600 integer words in the transmission protocol. The total cycle time from initiating the command in the operator station to the response is on average 800 milliseconds. Later in the year 2000 the A800 drive control systems will be replaced by RFC, starting with drive station 36. The control concept of the coal conveyor system will then be adapted step by step to the one of the pre-cut conveyor system. The hardware configuration of the TCP/IP coupling is shown below:

5. Diagnostics Workplace A diagnostics workplace provided in the new central control station serves for operative diagnostic checks by means of monitoring the behaviour of individual electrical components. This is an important help for preventive maintenance. The tools, specifically selected for each machine type, include · Advant Function Chart Builder Diagnosis of ABB Advant AC 450 · Network Control Center (NCC) Diagnosis of the OTN system · DIGSI Diagnosis of protective devices on medium-voltage switchgear · PC-Worx Diagnosis of Interbus S · SIMOVIS Diagnosis of inverters · VIBRONET Vibration monitoring · ELCAD View Navigation in the equipment documentation (single-line diagrams) The information supplied by the ABB control system in the form of · alarm lists · event logs · system lists · system status reports · status records is also used for diagnostic purposes. The diagnostics workplace is the integrating platform for all those tools and unites all software modules and communication interfaces required for maintenance and trouble-shooting. The workplace is open for remote access over the network. 5.1 Equipment The diagnostics workplace is equipped with a powerful industrial PC working on the terminal-server edition of Windows NT 4.0 and a Citrix Metaframe. The monitor and the keyboard are set up on one desk. An RS232 switch is used for making the necessary RS232 connections. Up to 32 such connections are possible. The selection of the RS232 connection required for a specific diagnostic tools is made by the software. Print-outs can be made on the printer installed in the central control station. 5.2 Software A menu system is used to facilitate the start-up of individual programmes and help orientation. The different applications can be chosen and started by an index. Additional activities that may become necessary, such as software-based switching of an RS232 channel, are performed automatically. The client software of the Metaframe system (ICA protocol) and the TCP/IP network connection make the workplace accessible for remote control.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923