K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Notice To prevent electrostatic discharge (ESD) from damaging the module, ground yourself using a grounding strap or by holding a grounded object, such as your computer chassis. 1. Touch the antistatic package to a metal part of the computer chassis. 2. Remove the module from the package and inspect it for loose components or other signs of damage.

NI-PXIe-6571-32-Channel Digital Pattern Instrument

4. When the installer completes, select Restart in the dialog box that prompts you to restart, shut down, or restart later. Digital Pattern Editor Use the Digital Pattern Editor to view, create, modify, and debug pin and channel maps, specifications, levels, timing, pattern, source waveform, and capture waveform files. You can also use the Digital Pattern Editor to configure the state of the digital pattern instrument. The Digital Pattern Editor is installed when you install NI-Digital Pattern Driver. For more information, refer to the Digital Pattern Help. Documentation for the Digital Pattern Instrument, NI-Digital Pattern Driver, and Digital Pattern Editor is available from the Start menu by navigating to NI Digital Pattern Documentation in the National Instruments folder. The primary help file is digipat.chm, and all other help files in the folder are embedded in digipat.chm.

NI-Digital Pattern Driver NI-Digital Pattern Driver LabVIEW API Use the NI-Digital VIs and properties in LabVIEW to configure and control the digital pattern instrument. The NI-Digital Pattern Driver LabVIEW API is installed by default when you run the installer. For more information, refer to the Digital Pattern Help. NI-Digital Pattern Driver .NET API You can optionally install and use the NI-Digital Pattern Driver .NET API to configure and control the digital pattern instrument. For more information, refer to the Digital Pattern Help. Documentation for the Digital Pattern Instrument, NI-Digital Pattern Driver, and Digital Pattern Editor is available from the Start menu by navigating to NI Digital Pattern Documentation in the National Instruments folder. The primary help file is digipat.chm, and all other help files in the folder are embedded in digipat.chm. NI-Digital Pattern Driver C API You can use the NI-Digital Pattern Driver C API dynamically linked library to configure and control the digital pattern instrument. Add a reference to C:Program Files (x86)IVI

Associated Drivers NI-DCPower The NI-DCPower driver is required to use NI-DCPower modules within the Digital Pattern Editor. For more information about using NI-DCPower modules within the Digital Pattern Editor, refer to the Digital Pattern Help. Visit ni.com/downloads to download NI-DCPower. NI-Sync The NI-Sync driver is required to support operations using the PXIe-6674T timing and synchronization module, such as combining comparison results across digital pattern instruments. For more information about using the PXIe-6674T with digital pattern instruments, refer to the Digital Pattern Help. Visit ni.com/downloads to download NI-Sync.

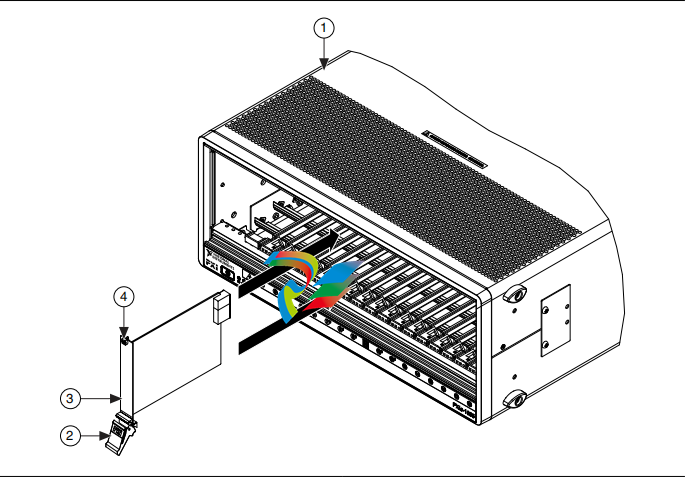

Installing the PXIe-6571 Note The PXIe-6571 requires an 82 W power and cooling capable chassis. Using the PXIe-6571 in a chassis with lower power or cooling capabilities will result in an error. 1. Ensure the AC power source is connected to the chassis before installing the module. The AC power cord grounds the chassis and protects it from electrical damage while you install the module. 2. Power off the chassis. 3. Inspect the slot pins on the chassis backplane for any bends or damage prior to installation. Do not install a module if the backplane is damaged. 4. Remove the black plastic covers from all the captive screws on the module front panel. 5. Identify the slot you will use in the chassis. If you plan to use the optional PXIe-6674T Timing and Synchronization Module, reserve the PXI Express System Timing Slot for its placement in the chassis. The following figure shows the symbols that indicate the slot types.

Table 3. Active LED Status Indicator Color Indications Off Instrument is not waiting for a trigger, not bursting a pattern, and not experiencing an error. During PPMU operations, the Active LED remains off. Amber Instrument awaiting Start trigger. Green Instrument received Start trigger and is bursting a pattern. Red Instrument error condition. Possible error conditions: • The instrument has detected an unlocked condition on a PLL that might result in incorrect data. To clear this error condition, reset the instrument programmatically or through Measurement & Automation Explorer (MAX). • The instrument has been disabled because it exceeded its overall power limit. To re-enable the instrument, reset it programmatically or through MAX. • The instrument has been disabled because it exceeded its overall temperature limit. To re-enable the instrument, cool the instrument to an acceptable range and resolve the environmental condition that caused the shutdown. Reset the instrument programmatically or through MAX, or power cycle the instrument.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923