K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

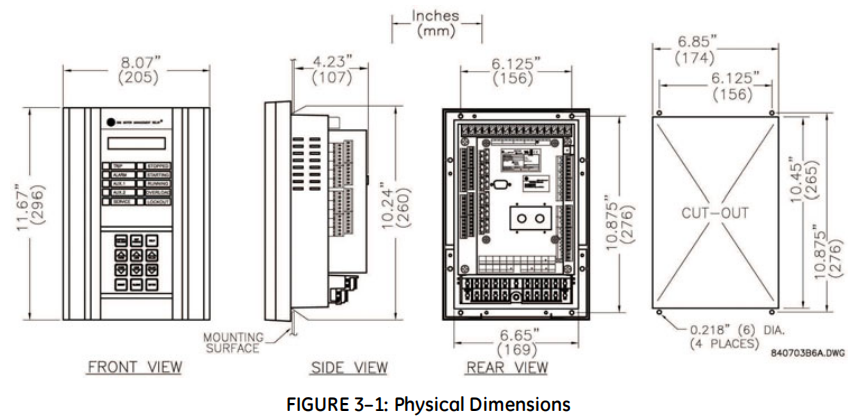

The 369 is contained in a compact plastic housing with the keypad, display, communication port, and indicators/targets on the front panel. The unit should be positioned so the display and keypad are accessible. To mount the relay, make cutout and drill mounting holes as shown below. Mounting hardware (bolts and washers) is provided with the relay. Although the relay is internally shielded to minimize noise pickup and interference, it should be mounted away from high current conductors or sources of strong magnetic fields

InstallationGE-369 Motor Management Relay

In this section, the terminals have been logically grouped together for explanatory purposes. A typical wiring diagram for the 369 is shown above in FIGURE 3–4: Typical Wiring for Motor Forward/Reversing Application on page 3–37 and the terminal arrangement has been detailed in FIGURE 3–3: TERMINAL LAYOUT on page 3–36. For further information on applications not covered here, refer to Chapter : Applications or contact the factory for further information. Hazard may result if the product is not used for intended purposes. This equipment can only be serviced by trained personnel. Do not run signal wires in the same conduit or bundle that carries power mains or high level voltage or currents. 3.3.3 Control Power VERIFY THAT THE CONTROL POWER SUPPLIED TO THE RELAY IS WITHIN THE RANGE COVERED BY THE ORDERED 369 RELAY’S CONTROL POWER. The 369 has a built-in switchmode supply. It can operate with either AC or DC voltage applied to it. The relay reboot time of the 369 is 2 seconds after the control power is applied. For applications where the control power for the 369 is available from the same AC source as that of the motor, it is recommended an uninterrupted power supply be used to power up the relay or, alternatively, use a separate DC source to power up. Extensive filtering and transient protection has been incorporated into the 369 to ensure reliable operation in harsh industrial environments. Transient energy is removed from the relay and conducted to ground via the ground terminal. This terminal must be connected to the cubicle ground bus using a 10 AWG wire or a ground braid. Do not daisy-chain grounds with other relays or devices. Each should have its own connection to the ground bus. The internal supply is protected via a 3.15 A slo-blo fuse that is accessible for replacement. If it must be replaced ensure that it is replaced with a fuse of equal size (see FUSE on page 2–13). 3.3.4 Phase Current (CT) Inputs The 369 requires one CT for each of the three motor phase currents to be input into the relay. There are no internal ground connections for the CT inputs. Refer to Chapter : Applications for information on two CT connections.

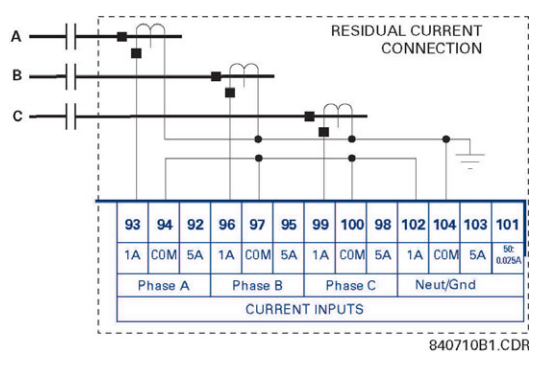

CHAPTER 3: INSTALLATION ELECTRICAL INSTALLATION 369 MOTOR MANAGEMENT RELAY– INSTRUCTION MANUAL 3–39 The phase CTs should be chosen such that the FLA of the motor being protected is no less than 50% of the rated CT primary. Ideally, to ensure maximum accuracy and resolution, the CTs should be chosen such that the FLA is 100% of CT primary or slightly less. The maximum CT primary is 5000 A. The 369 will measure 0.05 to 20 × CT primary rated current. The CTs chosen must be capable of driving the 369 burden (see specifications) during normal and fault conditions to ensure correct operation. See Section 7.4: CT Specification and Selection on page –230 for information on calculating total burden and CT rating. For the correct operation of many protective elements, the phase sequence and CT polarity is critical. Ensure that the convention illustrated in FIGURE 3–4: Typical Wiring for Motor Forward/Reversing Application on page 3–37 is followed. 3.3.5 Ground Current Inputs The 369 has an isolating transformer with separate 1 A, 5 A, and sensitive HGF (50:0.025) ground terminals. Only one ground terminal type can be used at a time. There are no internal ground connections on the ground current inputs. The maximum ground CT primary for the 1 A and 5 A taps is 5000 A. Alternatively the sensitive ground input, 50:0.025. can be used to detect ground current on high resistance grounded systems. The ground CT connection can either be a zero sequence (core balance) installation or a residual connection. Note that only 1 A and 5 A secondary CTs may be used for the residual connection. A typical residual connection is illustrated in below. The zero-sequence connection is shown in the typical wiring diagram. The zero-sequence connection is recommended. Unequal saturation of CTs, CT mismatch, size and location of motor, resistance of the power system, motor core saturation density, etc. may cause false readings in the residually connected ground fault circuit. FIGURE 3–5: Typical Residual Connection

The exact placement of a zero sequence CT to properly detect ground fault current is shown below. If the CT is placed over a shielded cable, capacitive coupling of phase current into the cable shield during motor starts may be detected as ground current unless the shield wire is also passed through the CT window. Twisted pair cabling on the zero sequence CT is recommended. FIGURE 3–6: Zero Sequence CT 3.3.7 Phase Voltage (VT/PT) Inputs The 369 has three channels for AC voltage inputs each with an internal isolating transformer. There are no internal fuses or ground connections on these inputs. The maximum VT ratio is 240:1. These inputs are only enabled when the metering option (M) is ordered. The 369 accepts either open delta or wye connected VTs (see the figure below). The voltage channels are connected wye internally, which means that the jumper shown on the delta connection between the phase B input and the VT neutral terminals must be installed. Polarity and phase sequence for the VTs is critical for correct power and rotation measurement and should be verified before starting the motor. As long as the polarity markings on the primary and secondary windings of the VT are aligned, there is no phase

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923