K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

ABB machinery drives are designed to meet the production

and performance needs of machine builders, system

integrators, panel builders and end users in a broad range

of applications. ACS850 drives are ideal for applications like

cranes, extruders, conveyors, winders, pumps, fans and

mixers in industries such as material handling, plastic and

rubber, food and beverage, textile and metals.

ABB ACS850 machinery drives

ABB machinery drives are designed to meet the production

and performance needs of machine builders, system

integrators, panel builders and end users in a broad range

of applications. ACS850 drives are ideal for applications like

cranes, extruders, conveyors, winders, pumps, fans and

mixers in industries such as material handling, plastic and

rubber, food and beverage, textile and metals.

The drives can be configured to meet the precise needs

of industries and order-based configuration is an integral

part of the offering. Covering a wide power and voltage

range with standard and optional features, the drives are

readily programmable, making their adaptation to different

applications easy.

Wide range of options

ACS850 drives offer a wide range of built-in options such

as different I/O and communications. A wide selection of

external accessories is also available. The flexibility and

programmability of the drives make them suitable for many

applications in different industries.

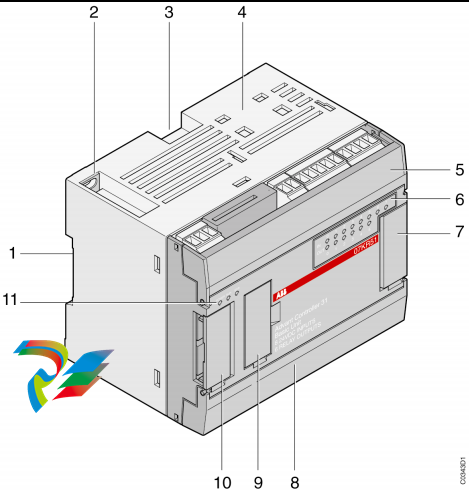

Introduction to ACS850

Robust design

The current ratings of ABB machinery drives are designed for

applications that have a high overload requirement. At the

heart of the drive is the motor control platform, direct torque

control (DTC) that provides accurate motor torque and speed

control even without feedback. The drive is designed for a

long working life and as such, parts like fans and capacitors

are selected to maximize their lifetime. This, together with

the extensive protection features and design details such

as coated boards, results in excellent reliability for the

demanding industrial market.

Optimized cabinet assembly

ACS850 drives are designed to be built into a customer’s

own cabinet, using minimal cabinet space while ensuring that

cabinet assembly is as easy as possible. The drives can be

mounted side-by-side and cabinet assembly documentation

is included. The documentation gives examples of different

cabinet configurations, examples of drawings and hints on

the selection of auxiliary equipment

Feature Advantage Benefi t

Modular and compact design

Compact size, side-by-side

mounting

Smallest frame size is only 93 mm (4 in) wide.

More drives can be placed in the same cabinet.

Optimum installation layout and efficient cabinet space

usage.

Space and cost savings.

Modular design Many standard features and a wide range of options

allow different system configurations.

Fits many application needs.

Offers flexibility in system design.

User interface and programming

Intuitive human-machine interface Large alphanumeric display showing different assistants

and macros.

Faster and more accurate drive configuration.

Optimal drive settings as assistants offer interactive help.

Drive programming and

configuration

Can replace relays and small PLCs with function block

programming.

Lower investment cost.

Higher flexibility in system design.

Memory unit for easy drive

management

Complete drive configuration and settings are stored in

a separate memory unit.

Power or control unit can be replaced without

parameter setting.

Drive functionality can be easily configured, modified or

updated with the memory unit.

Offers quick and easy after-sales service.

Designed for reliability

Robust main circuit design Enhanced reliability.

Coated boards and long lifetime components.

Cooling supervision (depending on frame size).

Less process interruptions.

Lower maintenance costs.

Extensive protection Advanced thermal protection of the drive

semiconductors and motor.

Higher process uptime.

Early warning of any production interruptions.

Maintenance assistant Indicates preventive maintenance needs of drive, motor

or machine.

Helps with maintenance schedules and cost control of

maintenance.

Diagnostic assistant Helps in locating failures or reasons for performance

changes and suggests remedies.

Reduced process downtime.

Optimized use

Energy saving calculator Monitors used and saved energy, displayed in kWh,

currency (€ or $) or volume of CO2 emission.

Easy to check the return on investment.

Load analyzer Shows the load profile of the drive. Easy process analysis.

Energy optimizer Maximizes efficiency by optimizing the motor flux. Improves motor performance therefore making the

process more efficient.

Control and performance

Compatible with these AC motors:

- induction

- permanent magnet

- synchronous reluctance

Same drive can be used to control different motor types. Savings in investment costs.

Standard drive-to-drive link,

configurable as Modbus link

Galvanic isolated connection for master-follower

communication or Modbus.

Lower investment costs.

More reliable, disturbance-free isolation.

Different communication options Supports most common communication protocols. Can be applied to several existing processes.

Integrated safe torque off function

(up to SIL 3)

High SIL class means high reliability of the safety

function.

Can also be used to implement Emergency Stop

without contactors.

Cost-effective and certified solution for safe machine

maintenance.

Fulfils IEC 61508, EN 62061 and EN ISO 13849-1

standards.

Extensive configurable

standard I/Os

Optimized accessibility. Lower cost.

Fewer parts and installation work needed for cabinet

assembly.

Optional I/O extensions Plug-in analog and digital I/O extensions. Extends drives’ scope, performance and applications

opportunities.

Direct torque control Accurate, dynamic and static speed and torque control.

Excellent process control even without pulse encoder.

High overload and high starting torque.

Less noise during motor operation.

Output frequency up to 500 Hz.

Enhanced motor identification at standstill.

Improves product quality, productivity and reliability.

Lower investment cost.

Less maintenance.

Suitable for use where audible noise is an issue.

Applicable in high speed applications.

Better process control due to more accurate identifi cation.

Motor identification without decoupling the load

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923