K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

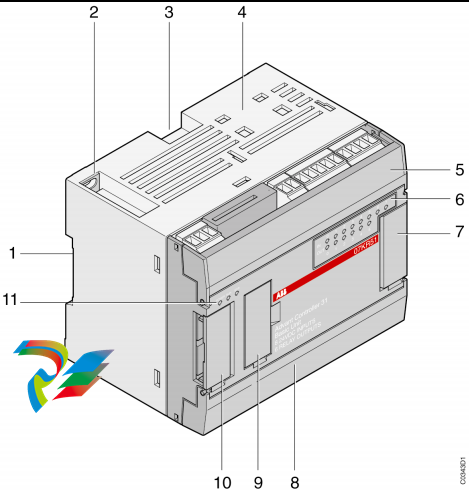

This publication describes the installation, operation, and maintenance of the Honeywell HC900 Process Controller. This publication includes the following sections.

Honeywell Digital Input, 24VDC (32 channel)900G32-0101

Chapter Title Page Content

Introduction 1 Model numbers, how to verify component compatibility, function description of

components, feature summary.

Components and

Architecture

17 Functional features and physical characteristics of the system and of each major

component of the HC900 Process Controller. Networking components and

methods of interconnection.

Pre-Installation

Planning

44 Pre-planning considerations and procedural guidelines for planning an installation.

Rack Installation 65 Procedures for installing the major components of the system: controller rack, I/O

expansion racks, and communication interconnections.

I/O Module

Installation and

Wiring

78 Procedures for installing I/O modules in the controller rack and I/O expansion

racks, and for wiring field devices to the terminal block associated with each

I/O module.

Communications

Installation

127 Guidelines for installing RS-232, RS-485 to USB cable, RS-485, and Ethernet

cabling and associated components.

Operating

Characteristics

155 Characteristics of the HC900 Process Controller as they relate to configuration of

a control strategy, and to operation of an installed and running system.

Redundant

Operating

Characteristics

165 Characteristics of redundant operation.

Diagnostics and

Troubleshooting

173 Mechanisms that detect and react to faults in the operation of HC900 Process

Controller hardware and/or software components.

Analog Calibration 191 Hardware configuration required for calibrating AI and AO modules from the

configuration software.

Removal and

Replacement

Procedures

196 Guidelines for replacing system components; includes Cautions and Warnings as

applicable.

Specifications 206 Details of HC900 Process Controller design and functioning.

Appendix -

Installation of

Remote

Termination Panels

(RTPs)

217 The Remote Termination Panel (RTP) provides an easy way to connect the

HC900 controller to the field wiring. The RTP integrates some of the typical

externally connected components, reducing wiring and setup time. It also

minimizes the need for multiple wires under a single screw connection by

expanding the connectivity of the shared terminals of the I/O modules.

Model Selection Guide

Legacy System

Description Model number SIL Compatible*

Racks

4 I/O Slot Rack 900R04 – 0001 No

8 I/O Slot Rack 900R08 – 0101 No

12 I/O Slot Rack 900R12 – 0101 No

8 Slot Rack -Red. Power 900R08R – 0101 No

12 Slot Rack - Red. Power 900R12R – 0101 No

Redundant CPU Rack 900RR0 – 0001 No

Controllers

Controller C50 CPU 900C52 – 02XX-00 No

Controller C30 CPU 900C32 – 02XX-00 No

Controller C70 CPU 900C72 – 01XX-00 No

Controller C70R CPU 900C72R – 01XX-44 No

Redundancy switch module 900RSM – 0001 No

I/O Scanner - 2 Port (1 per I/O rack) 900C73R – 01XX-44 No

I/O Scanner (for remote rack) 900C53 – 02XX-00 No

Redundant Power Status Module 900PSM – 0001 No

Power Supplies

120/240VAC, 60W 900P01 – 0001 No

120/240VAC, 28W 900P02 – 0001 No

+24VDC 900P24 – 0001 NA

I/O Modules

Analog Input (8 channel) 900A01 – 0102 No

High Level Analog Input (16 channel) 900A16 – 0001 No

Analog Output, 0 to 20mA, (4 channel) 900B01 – 0201 No

Analog Output, 0 to 20mA, (8 channel) 900B08 – 0001 No

Analog Output, 0 to 20mA, (16 channel) 900B16 – 0001 No

Digital Input, Contact type, (16 channel) 900G01 – 0102 No

Digital Input, 24VDC (16 channel) 900G02 – 0102 No

Digital Input, 24VDC (32 channel) 900G32 – 0001 No

Digital Input, 120/240 VAC, (16 channel) 900G03 – 0102 No

Digital Input, 120/240VAC, 125VDC (16ch-Iso) 900G04 – 0001 No

Digital Output, Relays ( 8 channel) 900H01 – 0102 No

Digital Output, 24VDC (16 channel) 900H02 – 0102 No

Digital Output, 24VDC (32 channel) 900H32 – 0001 No

Digital Output, 120/240 VAC (8 channel) 900H03 – 0102 No

Pulse/Frequency/Quadrature 900K01 – 0101 N

Description Model number SIL Compatible*

I/O Components

Low VoltageTerminal Block (Euro style) 900TEK – 0001 No

Low VoltageTerminal Block (Barrier Style) 900TBK – 0001 No

High VoltageTerminal Block (Euro style) 900TER – 0001 No

High Voltage Terminal Block (Barrier Style) 900TBR – 0001 No

High Density Terminal Block 900TCK – 0001 No

I/O Components

Analog Input Remote Terminal Panel (RTP) 900RTA – L001 NA

Relay Output Remote Terminal Panel (RTP) 900RTR – H001 NA

DI, DO, AO Remote Terminal Panel (RTP) 900RTS – 0001 NA

Low Voltage RTP Cable (1.0M, 3.28ft.) 900RTC – L010 NA

Low Voltage RTP Cable (2.5M, 8.2ft.) 900RTC – L025 NA

Low Voltage RTP Cable (5.0M, 16.4ft.) 900RTC – L050 NA

High Voltage RTP Cable (1.0M, 3.28ft.) 900RTC – H010 NA

High Voltage RTP Cable (2.5M, 8.2ft.) 900RTC – H025 NA

High Voltage RTP Cable (5.0M, 16.4ft.) 900RTC – H050 NA

High Density RTP Cable (1.0M, 3.28ft.) 900RTC – 3210 NA

High Density RTP Cable (2.5M, 8.2ft.) 900RTC – 3225 NA

High Density RTP Cable (5M, 16.4ft.) 900RTC-3250 NA

Filler Block Terminal Cover 900TNF – 0001 NA

Shield Terminal Strip (package of 2) 900TSS – 0001 NA

Terminal board jumpers (10, two pos jumpers) 900J02 – 0001 No

Terminal board jumpers (10, ten pos.jumpers) 900J10 – 0001 No

Manuals

Full Document set on CD 900ME1 – 00XX-XX NA

Software

HC Designer Config. Software CD 900W01 – 00XX-XX NA

HC Utilities Software/Documentation CD 900W02 – 00XX-XX NA

Kits & Accessories

Redundant Power, Rack Extension Kit 900RPE – 0001 NA

Spare I/O Label Kit 51452262 – 501 NA

Replacement Battery Kit 51500638 – 501 NA

Ethernet Cable (10 feet) 51451432 – 010 NA

Ethernet Cable (20 feet) 51451432 – 020 NA

Ethernet Cross-over Cable (20 feet) 51451996 – 020 NA

Null Modem Cable 51404755 – 501 NA

Null Modem Cable used with 900C70R 50004820 – 501 NA

250 ohm Shunt Resistor Kit ( (8/pkg.) 51205995 – 501 NA

Ethernet Switching Hub (8 Ports) 50008930 – 001 NA

24 VDC Power Supply 51452041 – 501 NA

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923