K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

All Panel 800 Version 6 are developed to satisfy the demands of human-machine communication. Built-in functions such as displaying and controlling text, dynamic indication, time channels, alarm and recipe handling are included.

ABB-PP877/3BSE069272R2Touch Screen

During Installation • The operator panel is designed for stationary installation on a planar surface, where the following conditions are fulfilled: – no high explosive risks – no strong magnetic fields – no direct sunlight – no large, sudden temperature changes • Install the operator panel according to the accompanying installation instructions. • Ground the operator panel according to the accompanying installation instructions. • Only qualified personnel may install the operator panel. • Separate the high voltage, signal and supply cables. • Make sure that the voltage and polarity of the power source is correct before connecting the operator panel to the power outlet. • Peripheral equipment must be appropriate for the application and location. • In a Zone 2 environment, this equipment shall be installed in an enclosure that provides a degree of protection not less than IP 54 or greater than IP 65 in accordance with IEC/EN 600079-0. The IP rating of the equipment is limited to the IP rating of the enclosure it is to be installed into. • In a Zone 22 environment, this equipment shall be installed in an enclosure that provides a degree of protection not less than IP 64 or greater than IP 65 in accordance with IEC/EN 600079-0. The IP rating of the equipment is limited to the IP rating of the enclosure it is to be installed into.

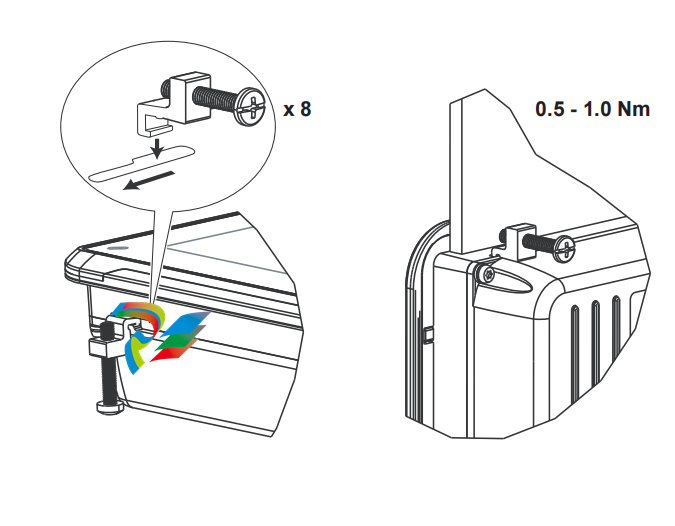

Installation Process The following is needed: • A Phillips/slot screwdriver 1. Unpack and check the delivery. If damage is found, notify the supplier. 2. Place the operator panel on a stable surface during installation. Dropping the operator panel or letting it fall may cause damage. 3. To cut a correct opening for the operator panel, use the cut out dimensions in the outline drawing. For more information, see sections Operator Panel Drawings and Technical Data. 4. Secure the operator panel in position using all the fastening holes and the provided brackets and screws:

5. Connect the cables in the specified order, according to the drawing and steps below. • The operator panel must be brought to ambient temperature before it is started up. If condensation forms, ensure that the operator panel is dry before connecting it to the power outlet. • Ensure that the operator panel and the controller system have the same electrical grounding (reference voltage level), otherwise errors in communication may occur. • Ensure that the voltage and polarity of the power source is correct. • Separate high voltage cables from signal and supply cables. • Shielded communication cables are recommended.

In some industrial units for Ethernet, the RJ45 contact’s shield is connected to the chassis via a capacitor, see 1 in drawing above. The operator panel’s Ethernet shield is directly connected to the chassis, see 2 in drawing above. 1. Check whether the other Ethernet unit has its shield directly grounded or grounded via a capacitor. In many cases, connecting the shielded Ethernet cabling to the chassis at both ends is inappropriate. Hum or grounding loops can occur. Unshielded cabling may even result in fewer communication errors. A good solution may be to use a shielded Ethernet cable, but to connect the shield at one end only. One option is to break the shield, see 3 in drawing above.

To Achieve Better EMC Protection • Use shielded cables for RS232 communication. • Use twisted pair and shielded cabling for RS422 and RS485. • Use the cabling intended for the bus type; Ethernet, Profibus, CC-Link, CAN, Device Net etc. • Install and connect according to applicable specifications for the relevant bus standard. • Use shielded cabling for Ethernet, preferably with foil and a braided shield. • D-sub covers should be shielded, and the shield should be connected to the cover 360° where the cable enters. • Connect the shield at both ends. Shielded cable Not same potential Ground plane 1 Ground plane 2 Ground plate Ground plate in another building 0.1 μF/250 V With longer distances, there is a risk that the ground potential may be different. In that case, the shield should only be connected at one end. A good alternative is to connect the other end of the shield to the ground via a 0.1 µF/250 V plastic capacitor. Both ends are then connected to the ground in terms of HF, but only connected to the ground at one end in terms of LF, thus avoiding the 50/60 Hz grounding loops.

Metal cabinet Metal cabinet Terminal or connector Terminal or connector EMC cable gland Plastic cable gland Shielded cable Cable clamp in steel Shielded cable

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923