K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Estimated Shipping Size

Dimensions: 10.0" x 4.0" x 6.0"

(25.4 cm x 10.2 cm x 15.2 cm)

Weight: 1 lbs 9.0 oz (0.7kg )

Tariff Code: 9032900000

Country of Origin: United States

Ships from Webster NY, USA

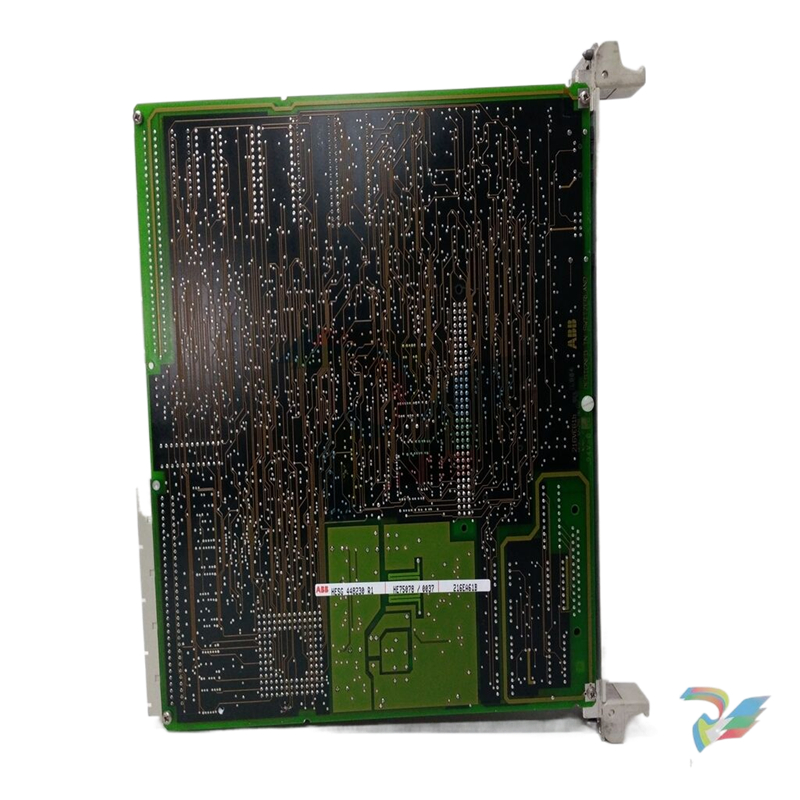

ABB GJR5253000R0200 07KT97 Central Unit

Product Overview

Model details: ABB GJR5253000R0200 07KT97 is a central unit product. ‘GJR’ may represent a product family, followed by a numerical number to distinguish between different configurations or versions of the product. ‘07KT97’ may be a specific code for this product, used for accurate identification in ABB's catalogue or control system.

Central position: As a central unit, it plays a key pivotal role in industrial automation systems or other complex control scenarios, similar to a command centre, coordinating the operation of various subsystems and devices.

Performance characteristics

Powerful processing capabilities

Data processing speed: This central unit is likely to have high-speed data processing capabilities, able to quickly receive, parse and process signals from multiple devices. For example, in a large-scale industrial automation scenario, it may be able to process thousands of data points per second, including information on temperature, pressure, flow rate, etc., collected by sensors, thus ensuring that the system can respond to changes in real time.

Multi-tasking capability: It can perform multiple tasks simultaneously, such as running control algorithms, performing data logging, and monitoring communication status. This makes it possible to effectively coordinate the work of different devices in complex industrial environments, such as controlling multiple motors, valves and robots in a production line at the same time.

Communication Functions

Types of communication interfaces: It is expected to be equipped with a variety of communication interfaces, such as an Ethernet interface for high-speed data transmission and remote monitoring, and an RS-232 or RS-485 interface for connecting to conventional industrial equipment. These interfaces enable communication with different types of sensors, actuators and other control systems.

Communication protocol support: It supports common industrial communication protocols, such as Modbus, Profibus - DP, etc. Through these protocols, it can communicate with different types of sensors, actuators and other control systems. Through these protocols, it can work seamlessly with different brands of equipment, enhancing the compatibility and scalability of the system. For example, in a factory environment with mixed equipment, it can communicate with a Siemens PLC via Profibus - DP protocol, and at the same time exchange data with sensors of other brands using Modbus protocol.

Reliability and Stability

Hardware Reliability: High-quality electronic components are used and undergo rigorous quality testing to ensure that failures are minimised in long-term operation. For example, its circuit boards may feature multi-layer wiring and high-quality chips that can withstand a certain level of electromagnetic interference, temperature variations and mechanical vibration.

Redundant design (possible): To cope with the failure of critical components, a redundant design may have been adopted. For example, a power supply module may have a backup power supply, or a critical communication line may have a backup channel so that when one part fails, the other can be automatically switched over to ensure continuous system operation.

Expandability and Flexibility

Module Expansion Function: It is expandable and able to increase functions by adding expansion modules. For example, input/output modules can be added to increase the number of I/O points of the system to adapt to the changing needs of industrial production, such as new production lines or new monitoring points.

Software Configurability: The software aspect should be highly flexible, allowing the user to customise its functionality through the programming software. For example, users can write control logic according to different production processes, set alarm thresholds, and configure the format and period of data logging.

OTHER INFORMATION

• 60 amps size

• 500 volt DC ratings

• 160 and 300 volt DC normal closed ratings for dynamic braking

• Low energy auxiliary contacts available (17V, 5mA)

• Mechanically interlocked version available for reversing applications

• Small compact design

• 2 pole (2 N.O.) and 3 pole (2 N.O. & 1 N.C.) available

• Additional auxiliary contact blocks available

• Auxiliary contacts available to meet elevator standards

• Fast, snap-on DIN rail mounting

• Double break contact design

• Captive terminal screws

• Touch-safe design: all connection terminals are protected against accidental touch

• Terminals supplied open for ease of wiring

• Operates over an extended voltage range of 85% to 110% of rated control voltage

• N.C. dynamic braking pole is easily added to two pole contactors

• Screwdriver guide holes

• Snap-on front mounted accessories

• UL and CSA approved

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923