K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Estimated Shipping Size

Dimensions: 10.0" x 4.0" x 5.0"

(25.4 cm x 10.2 cm x 12.7 cm)

Weight: 1 lbs 16.0 oz (0.9kg )

Tariff Code: 8537109060

Country of Origin: Sweden

Ships from Webster NY, USA

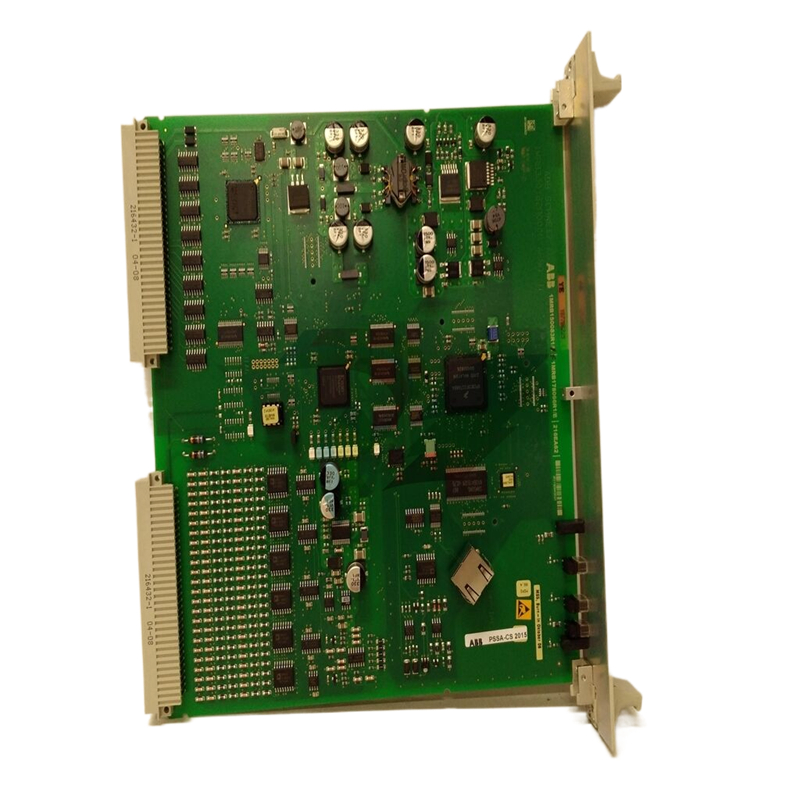

ABB GJR5253000R0260 07KT97 Central Unit

Basic information

Model identification: ABB GJR5253000R0260 07KT97 is a central unit product. This model number is a specific identification in the ABB product system, which helps to identify and classify the product accurately.

Series and use: It is assumed from the naming that it belongs to ABB's industrial control equipment series, as the central unit, it is the core part of the whole control system, similar to the brain of the human body, responsible for coordinating and managing the operation of all kinds of industrial equipment and sub-systems.

Performance characteristics

Computing and control functions

Highly efficient data processing: The central unit has powerful computing power and can quickly process large amounts of data from different devices. For example, in an automated production line, it can simultaneously receive temperature, pressure, position and other data sent by multiple sensors, analyse them in real time, and accurately make control decisions according to preset algorithms and logic, such as controlling the speed of motors and the opening of valves.

Precise control strategy: It supports a variety of complex control strategies, such as PID (Proportional-Integral-Differential) control, fuzzy control and so on. Taking PID control as an example, it can accurately adjust the process variables so that the output of the system can quickly and stably reach the set value, effectively improving the control accuracy and stability of industrial processes.

Communication Performance

A variety of communication interfaces: It is equipped with a wealth of communication interfaces, including but not limited to Ethernet interface, RS-485 interface, CAN bus interface and so on. The Ethernet interface can be used for high-speed data transmission and remote monitoring, connecting the system to the factory LAN or the Internet, which is convenient for operators to monitor and manage the whole system from remote terminals; the RS-485 interface is suitable for connecting multiple distributed devices, such as sensors and actuators, to build a reliable fieldbus network; the CAN bus interface is widely used in the field of automobile manufacturing and other fields, used for the communication between modules within the vehicle electronic system. CAN bus interface is widely used in automotive manufacturing and other fields for communication between various modules within the vehicle electronic system.

Communication protocol support: It supports a variety of industrial communication protocols, such as Modbus, Profibus, Ethernet/IP, etc. These protocols enable the central unit to communicate with other devices, such as sensors and actuators, to build a reliable fieldbus network. These protocols enable the central unit to communicate seamlessly with equipment produced by different manufacturers, achieving system openness and compatibility. For example, in an industrial environment with mixed equipment, it can communicate with Siemens PLCs (Programmable Logic Controllers) via the Profibus protocol, and at the same time with Schneider inverters via the Modbus protocol, effectively integrating the resources of different brands of equipment.

Reliability and Stability

Redundant design: To ensure continuous and stable operation in harsh industrial environments, the central unit may have a redundant design. For example, there may be dual power supply redundancy backup in the power supply module, so that when one power supply fails, the other power supply can immediately take over to ensure normal power supply to the equipment; there may also be redundancy design in the processor and key communication modules to prevent a single point of failure leading to system paralysis.

Hardware quality and protection: High-quality electronic components are used, which are strictly screened and tested for high reliability and durability. The shell design has good electromagnetic shielding performance, which can effectively prevent external electromagnetic interference on the internal circuitry; at the same time, it also has a certain degree of dust-proof, waterproof and shock-resistant ability to adapt to a variety of complex industrial site environment.

Expandability and Flexibility

Module expansion capability: good scalability, allowing users to add a variety of functional modules according to actual needs. For example, when it is necessary to add new input and output points, it can be achieved by adding I/O expansion modules; if you want to integrate new communication protocols or functions, you can insert the corresponding communication modules or function expansion cards. This modular design allows the system to flexibly adapt to changes in production processes and upgrade requirements.

Flexibility of software programming: It supports a variety of programming languages and programming methods, such as ladder diagrams, instruction lists, structured text and so on. Users can choose the appropriate programming method according to their programming habits and specific control tasks. For example, for simple logic control tasks, using ladder diagram programming can be more intuitive and convenient; while for complex mathematical operations and data processing tasks, structured text programming is more advantageous. This flexibility allows users to quickly and efficiently develop control programmes that meet practical needs.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923