K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

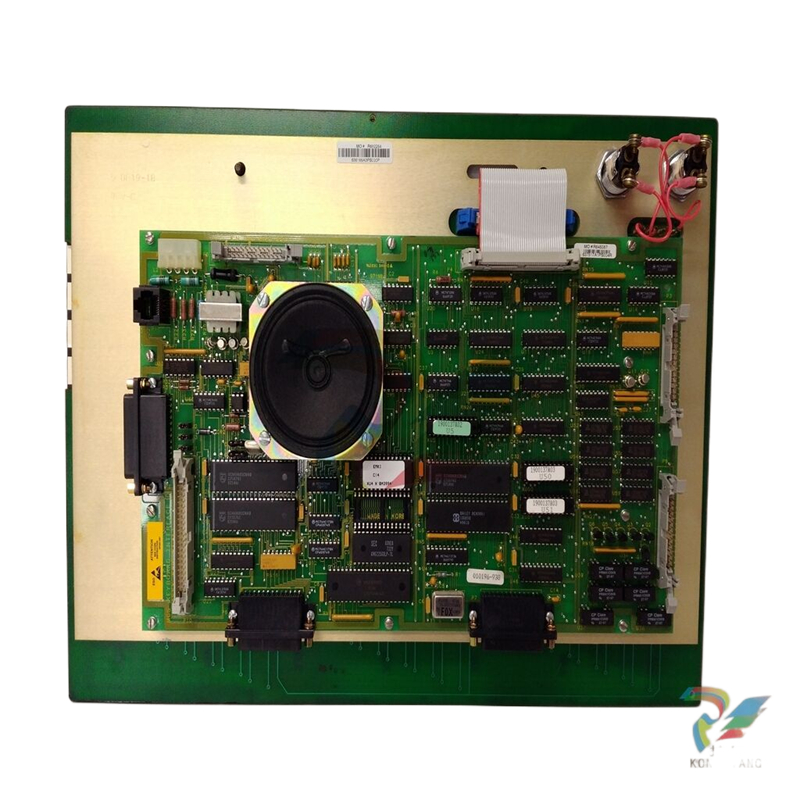

ABB P-HC-DOC-0001000 Network TU Module

Functional Characteristics

Network connection and communication: This module is mainly used to build and expand the network architecture and achieve stable communication between devices. It can support a variety of network protocols and communication interfaces, so that different types of equipment can easily access the network to ensure the accurate transmission and interaction of data in the network, so as to achieve the efficient operation of the entire system.

Signal Conversion and Processing: With signal conversion function, it can convert signals of different formats or levels so that they can be transmitted in the network. At the same time, the necessary processing of the transmitted data, such as data encoding, decoding, checking, etc., to improve the reliability and integrity of the data and reduce data transmission errors.

System Integration and Expansion: As an important part of the system, it can be seamlessly integrated with other ABB devices and modules, such as controllers, I/O modules, etc., to build a complete automation control system together. By adding this network terminal unit module, you can easily expand the network coverage of the system and the number of connected devices, to meet the needs of industrial automation applications of different sizes and complexity.

Technical Parameters

Network protocol support: support common industrial network protocols, such as Profibus, Modbus, Ethernet/IP, etc., according to the actual application scenarios and equipment compatibility requirements to select the appropriate protocol to ensure good communication with other devices.

Communication interface type: Usually equipped with a variety of communication interfaces, such as Ethernet interface (RJ45), serial interface (RS-232, RS-485), etc., in order to adapt to the connection needs of different devices. Different interfaces have different transmission rates and communication distance limitations, and can be configured and used according to specific circumstances.

Working voltage and power consumption: the working voltage is generally a specific DC voltage, such as +12V or +24V, etc., the specific voltage value depends on the model and design of the module. The power consumption is low, which can reduce the energy cost of the system under the premise of ensuring normal operation.

Application Areas

Industrial automation control system: In various industrial production processes, such as automotive manufacturing, chemical, pharmaceutical, food and beverage industries, used to connect the production line of various devices, such as sensors, actuators, controllers, etc., to achieve the automation of the production process of monitoring and controlling, improve production efficiency, product quality and equipment reliability.

Energy Management System: In the field of power, oil, natural gas and other energy, it can be used to build energy monitoring and management network, connecting energy metering equipment, monitoring equipment, smart meters, etc., to achieve real-time monitoring of energy consumption, data analysis and optimisation of management, to help enterprises to reduce energy costs and improve the efficiency of energy use.

Intelligent Building and Facility Management: In intelligent buildings, it is used to connect and control various equipments and systems in the building, such as air-conditioning system, lighting system, security system, lift control system, etc., so as to realise the intelligent management and control of the building, and to improve the comfort, safety and energy use efficiency.

Learning objectives

Upon completion of this course the participants will be able to:

- Plan an appropriate architecture for a system 800xA with Advant Master

- Install the AC450 Connect software

- Navigate in the system and create new objects / aspects

- Configure and maintain the communication between 800xA and Advant controllers

- Configure and modify graphic displays, faceplates and graphic elements

- Manage and configure alarm and events

- Configure historical data collection and trends

- Configure time synchronization

- Create and customize a workplace

- Configure user accounts and describe how access rights work

- Save and restore data.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923