K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

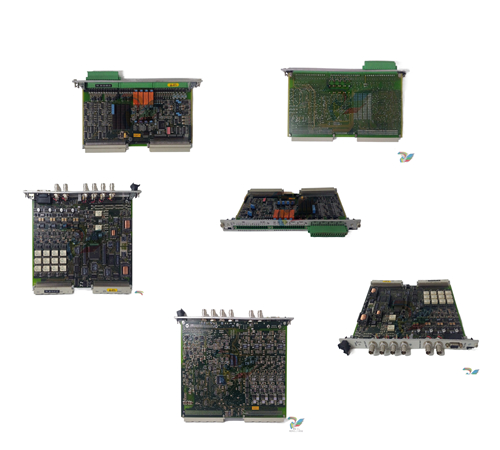

ABB PGM07 Rack PGM 07 H&B Contronic

Basic Information

Dimensions: approx. 445px x 127.49999999999999px x 825px, weight approx. 0.3kg.

Place of origin: Sweden.

Warranty period: usually 1 year.

Performance Characteristics

High-precision Signal Acquisition: It is capable of high-precision acquisition of analog signals, accurately converting various analog physical quantities on the site into digital signals for processing and analysis by the control system, which ensures the accurate measurement and control of parameters in the industrial process.

Multi-channel input: generally has multiple analog input channels, can receive analog signals from multiple sensors at the same time, such as temperature, pressure, flow, level and other sensor signals, to achieve simultaneous acquisition of a number of different physical quantities, to facilitate centralized monitoring and management.

Wide signal range: It can receive a variety of types and ranges of analog input signals, and the common input signal ranges include voltage signals (e.g., 0-10V, -10V-+10V) and current signals (e.g., 4-20mA), which are compatible with a variety of industrial standard sensors.

Strong anti-interference ability: Effective anti-interference measures, such as shielding, filtering and other technologies, can work stably in harsh electromagnetic environments to ensure the accuracy and reliability of the collected analog signals.

Application Fields

Industrial automation production line: It is used to monitor the operation status of production equipment, such as the current and temperature of the motor and the speed of the conveyor belt, etc. By collecting these analog signals, it can discover the abnormal situation of the equipment in time and ensure the normal operation of the production line.

Process control system: in chemical, electric power, water treatment and other industries, real-time monitoring and control of key parameters in the process, such as temperature, pressure, liquid level, flow rate, etc., to ensure the safety, stability and efficiency of the production process.

Energy management system: collects energy-related analog signals, such as power generation, power consumption, flow rate, etc., realizes real-time monitoring and management of energy, and provides data support for reasonable distribution of energy and energy saving.

Main features

· 24 digital inputs with LED displays

· 16 digital transistor outputs with LED displays

· 8 digital inputs/outputs with LED displays

· 8 individually configurable analog inputs 0...10 V, 0...5 V, ±10 V, ±5 V, 0...20 mA, 4...20 mA, differential inputs, Pt100 (2-wire or 3-wire), the analog inputs are also individually configurable as digital inputs

· 4 individually configurable analog outputs ±10 V, 0...20 mA, 4...20 mA

· 2 counters for counting frequencies up to 50 kHz, configurable in 7 different operating modes · 1 CS31 system bus interface for system expansion

· 1 interface for connecting communication modules (e.g. 07 KP 90)

· 2 serial interfaces COM1, COM2

– as MODBUS interfaces and

– for programming and test functions

· Real-time clock

· LEDs for displaying operating conditions and error messages

· Detachable screw-type terminal blocks

· Fastening by screws or by snapping the device onto a DIN rail

· The lithium battery 07 LE 90 can be put into the battery compartment in order to

– store and backup the user program in the RAM

– store and backup data which is additionally contained in the RAM, e.g. the status of flags

– backup the time and date (real-time clock)

· RUN/STOP switch for starting and aborting the program execution

· Extensive diagnosis functions

– self-diagnosis of the basic unit

– diagnosis of the CS31 system bus and the connected modules

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923