K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

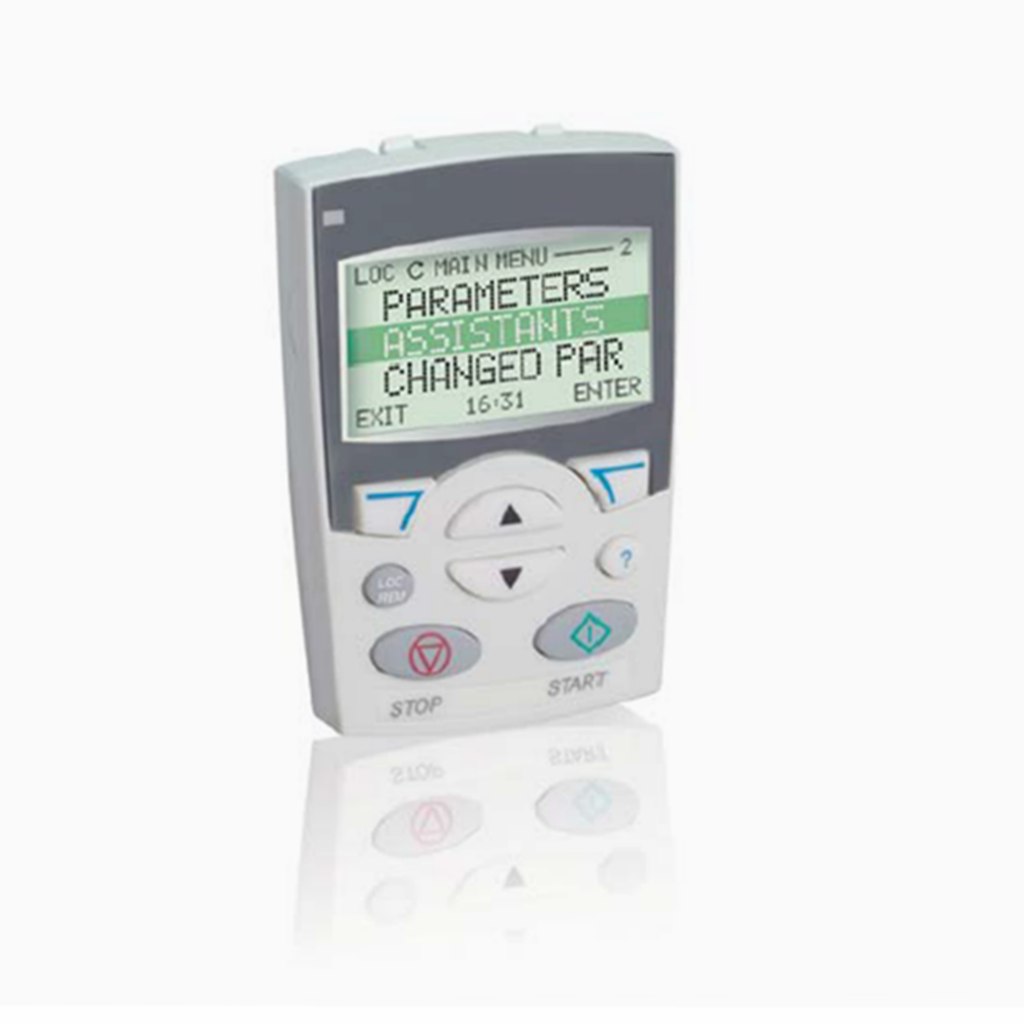

ABB POT 73 Membrane Keyboard POT 73 H&B Contronic

Technical parameters

Interface type: Standard interfaces, such as USB or RS-232, are usually used to facilitate the connection with the host computer or other control devices of the H&B Contronic system. The use of standard interfaces also makes it easy to replace the keypad in the event of a malfunction or to connect it to other compatible devices.

Key Life: The life of a keypad can reach millions of presses, depending on the material and design of the keypad. For example, some of the major function keys may have a life expectancy of more than 5 million keystrokes, which ensures the reliability of the keyboard over long periods of frequent use.

Working environment parameters: able to work in a wide range of temperature (e.g. - 10 ℃ - +50 ℃) and humidity (e.g. 10% - 90% relative humidity), to adapt to different industrial environments and working conditions.

Application Scenarios

Industrial automation control: In industrial automation control system, it is used for parameter setting, control command input and operation status query of various automation equipments. For example, in an automated production line, the keyboard can be used to program a PLC (Programmable Logic Controller), set the working path of a robot, or adjust the speed of a conveyor belt.

Process control system: In process control systems such as chemical, electric power, water treatment, etc., the operator can use the keyboard to enter the set values of process parameters, such as temperature, pressure, flow rate and other control parameters, and at the same time, can also view real-time operating data and alarm information of the system to adjust the system operating status in time, to ensure the safety and stability of the production process.

Equipment monitoring and maintenance: In the equipment monitoring room or maintenance site, technicians can log into the equipment monitoring system through the keyboard to view the equipment's historical data, fault records and other information, and can use the keyboard to enter maintenance commands, such as equipment restart, calibration, and other operations, to facilitate the maintenance and management of equipment.

Learning objectives

Upon completion of this course the participants will be able to:

- Plan an appropriate architecture for a system 800xA with Advant Master

- Install the AC450 Connect software

- Navigate in the system and create new objects / aspects

- Configure and maintain the communication between 800xA and Advant controllers

- Configure and modify graphic displays, faceplates and graphic elements

- Manage and configure alarm and events

- Configure historical data collection and trends

- Configure time synchronization

- Create and customize a workplace

- Configure user accounts and describe how access rights work

- Save and restore data.

APPLICATIONS

• Simulation

• Instrumentation

• Industrial control

• Process control and monitoring

• Factory automation

• Intelligent networked PLC controllers

• Automated test

• Data acquisition

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923