K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

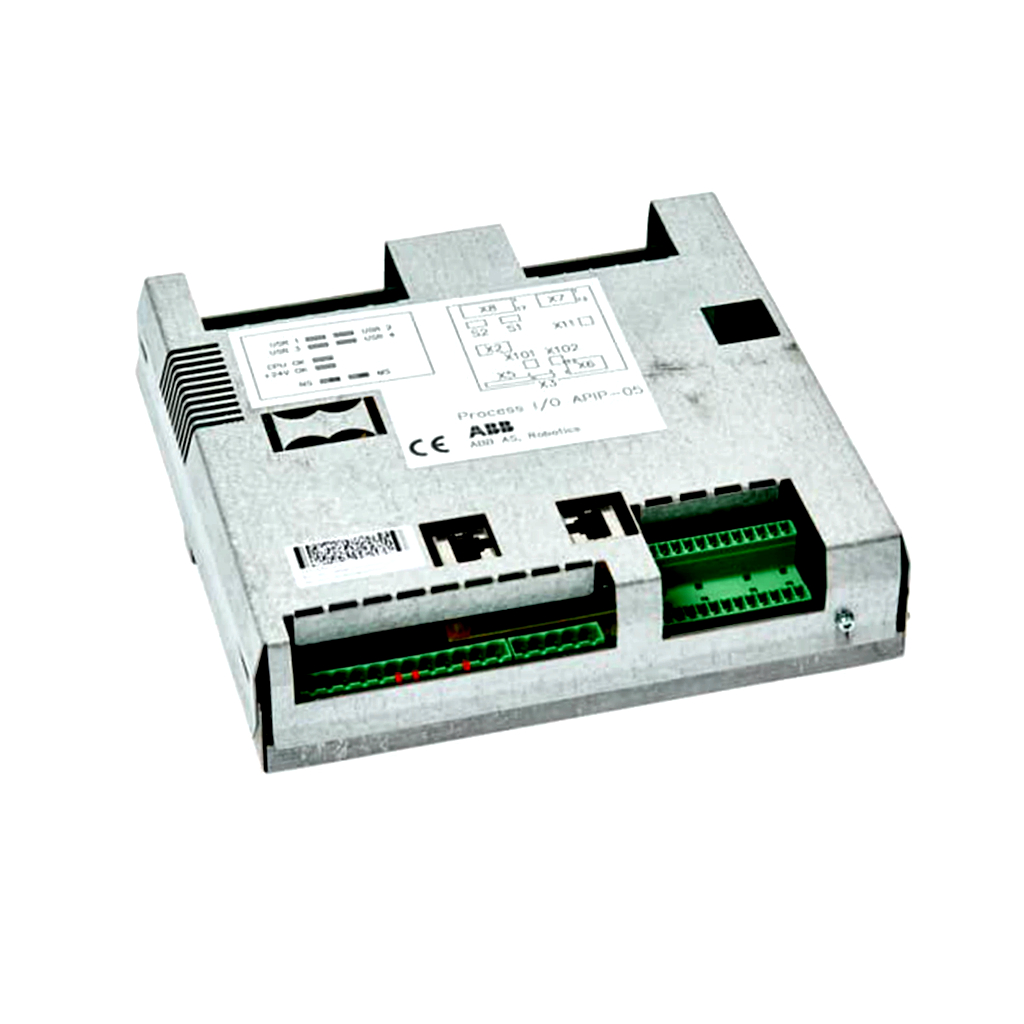

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS, ABB Procontic, ABB Procontic CS31

Estimated Shipping Size

Dimensions: 6.0" x 3.3" x 3.8"

(15.2 cm x 8.3 cm x 9.5 cm)

Weight: 0 lbs 10.5 oz (0.3kg )

Country of Origin: France

Ships from Webster NY, USA

ABB 1SBP260109R1001 XO08R2 Relay Output Extension Module

Technical parameters

Input and output parameters: The module has 8 digital output signal channels, which can extend the output of ABB relay. The output signals are usually dry contact signals, which can withstand a certain load current and voltage, generally each output can carry a current of about 2A/3A, and the voltage range is 24VDC or 120-230VAC 50/60Hz, etc. The module has a good electrical isolation between the inputs and outputs.

Electrical isolation characteristics: the input and output of the module have good electrical isolation performance, the isolation voltage can be up to thousands of volts, which can effectively prevent the spread of electrical interference and faults to ensure the safety and stability of the system.

Working power requirements: usually need to provide a stable external power supply, the working voltage is generally 24VDC or 220VAC and other common industrial power supply voltage, power consumption is relatively low, generally between a few watts to a dozen watts.

Functional features

Signal Expansion Function: The output signals of ABB relay can be expanded to as many as 8 digital output signals, so as to realise more control functions in the electrical control system, and to meet the demand of controlling multiple electrical devices at the same time.

Strong compatibility: the module can be seamlessly integrated with other ABB industrial automation products, such as ABB's Advant controller, Procontic series, etc., which is convenient for users to expand and upgrade the system.

Multiple Protection Functions: The module has a variety of built-in protection functions, such as over-current protection, over-voltage protection and under-voltage protection, etc., which can effectively protect the equipment and system from over-current, over-voltage and under-voltage faults and other damages.

Easy to configure and control: It supports a variety of programming languages and communication protocols, such as common Profibus, Modbus, TCP/IP, etc., which is convenient for users to configure and control. Through simple programming and setting, users can easily achieve control and monitoring of various electrical devices.

Application Areas

Industrial automation production line: In various industrial automation production lines such as automobile manufacturing, electronic product manufacturing, food and beverage production, etc., it can be used to control the start-stop and operation state switching of all kinds of production equipments, such as controlling the operation of conveyor belts, the action of robots, and the switching of cutting tools of processing equipments.

Process control system: in the chemical industry, petroleum, electric power and other process industries, can be used to control the switching output of various process control equipment, such as controlling the opening and closing of valves, pump start and stop, the heating device on and off, etc., to achieve accurate control and monitoring of the production process.

Intelligent building automation system: In the HVAC system, lighting system and security system of intelligent buildings, it can be used to control the start and stop of air-conditioning units, wind speed adjustment of fan coils, switching of lighting fixtures and access control system, etc., so as to realise the intelligent control and management of building equipment and improve the energy efficiency and comfort of the building.

FEATURES

• Process Station with integrated fieldbus capability

• 4 high-speed fieldbus lines

• Supports different fieldbus types, even simultaneously: PROFIBUS-DP, up to 12 MBd Modbus CAN Foundation Fieldbus H1 (with LD800 HSE)

• Easy engineering: fully integrated in Control Builder F

• One unified database for field devices shared by the control level and the Human System Interface (HSI)

• Module recognition with factory and operational parameters

• Comprehensive diagnostics for proactive maintenance

• Compact, rugged design

• Front panel connectors

• DIN Rail (C-rail) or wall mounting for easy installation

• Ambient temperature 0-60 °C (32-140 °F) with temperature monitoring

• EMC certification according to EN50082

• Certification: CE, NAMUR, CSA, UL, EN61000-6-2.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923