K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Description

**ABB AI825: The Pinnacle of Automation Excellence**

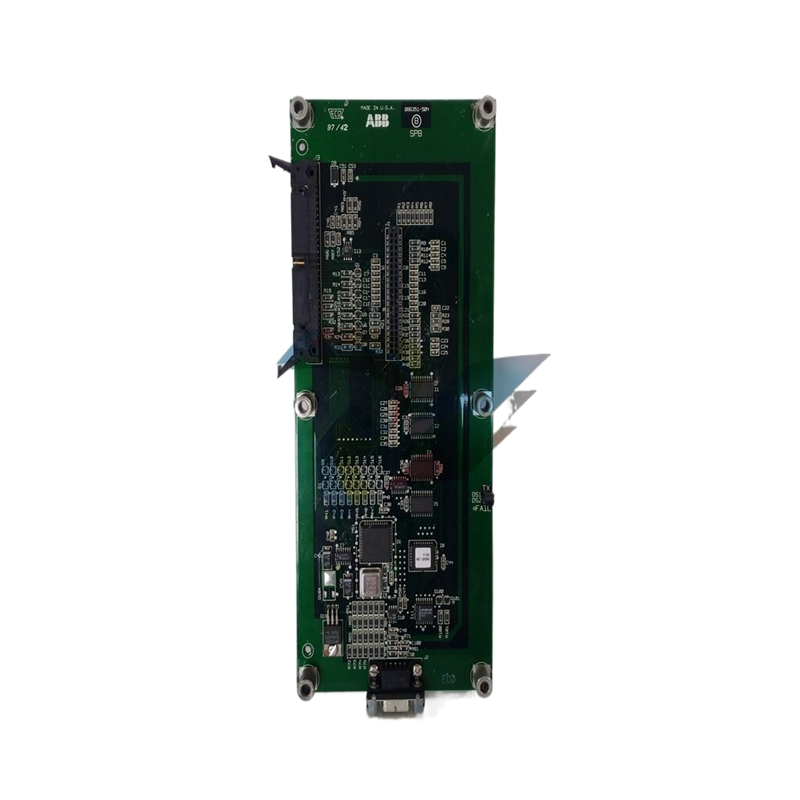

ABB AI825 - | 3BSE036456R1 | 4 Channel Analog Input Module

ABB AI825 - | 3BSE036456R1 | 4 Channel Analog Input Module

**ABB AI825: The Pinnacle of Automation Excellence**

The ABB AI825 is an advanced automation solution designed specifically for demanding applications in the power industry, petrochemical sector, and general automation environments. Renowned for its robust performance, the AI825 integrates seamlessly into existing systems, enhancing operational efficiency and reliability.

**Key Technical Features**

The ABB AI825 boasts an impressive input/output capacity, supporting a wide range of configurations to suit various operational needs. With a high-speed processor and extensive memory, this model ensures fast data processing and real-time monitoring, making it ideal for critical applications. The durability of the AI825 is another key feature, as it is engineered to withstand harsh environmental conditions typical in industrial settings, including high temperatures, moisture, and electromagnetic interference. Performance metrics indicate that the AI825 can handle complex algorithms and large datasets with remarkable efficiency, providing accurate results that enhance decision-making processes.

**Real-World Usage Scenarios**

In the power industry, the ABB AI825 excels in optimizing grid management and renewable energy integration. Its ability to process real-time data allows utilities to make informed decisions regarding load distribution and energy consumption. In petrochemical applications, the AI825 can effectively monitor and control processes, ensuring safety and compliance while maximizing production efficiency. Furthermore, in general automation, this model is integral for automating repetitive tasks, thereby reducing human error and increasing overall productivity.

**Comparison with Other ABB Models**

When compared to other models within the ABB family, such as the ABB ACS880-01-206A-3 frequency converter and ABB IRB 7600 Series robots, the AI825 stands out due to its specialized functionality in data processing and automation management. While the ACS880 focuses on drive control, the AI825 provides a broader automation framework, making it a versatile choice for various industries. Additionally, the ABB SDCS-PIN-48-SD/3BSE004939R1012 pulse transformer board complements the AI825 by offering enhanced signal processing capabilities, ensuring that data integrity is maintained across all operational levels.

**Complementary ABB Models**

The robustness of the ABB AI825 is further enhanced when used in conjunction with other ABB automation products. For instance, integrating the ABB 3HAC022279-007 gearbox can improve mechanical performance, while the ABB 07AI91 controller offers additional control capabilities for complex systems. The ABB PM856AK01 processor unit enhances computational power, allowing the AI825 to manage larger datasets efficiently. The ABB DSDC110B control unit works in harmony with the AI825, providing a comprehensive automation solution that is both reliable and efficient.

Moreover, the ABB YB56103-BD/1 PC board can serve as a powerful interface for data communication, while the ABB 3HAC026660-003 module can expand the I/O capabilities of the AI825, making it suitable for more intricate control systems. For applications requiring detailed monitoring, the ABB 3BHE039905R0101 can be utilized alongside the AI825 to provide enhanced diagnostic capabilities. The ABB GJR2392500R1210 output module can be used to facilitate signal transmission, ensuring that the AI825 communicates effectively with other components in a control system.

**Conclusion**

In conclusion, the ABB AI825 is a powerful automation tool that excels in various industrial applications, particularly in the power industry, petrochemical sector, and general automation. Its unique technical features, coupled with its ability to integrate with other ABB automation products, make it an essential component for businesses aiming to enhance efficiency and reliability. With the ABB AI825, organizations can leverage advanced technology to streamline operations and achieve their automation goals.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923