K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

Brand

Description

Introducing the ABB FENA-21: Elevating Automation with Precision and Versatility

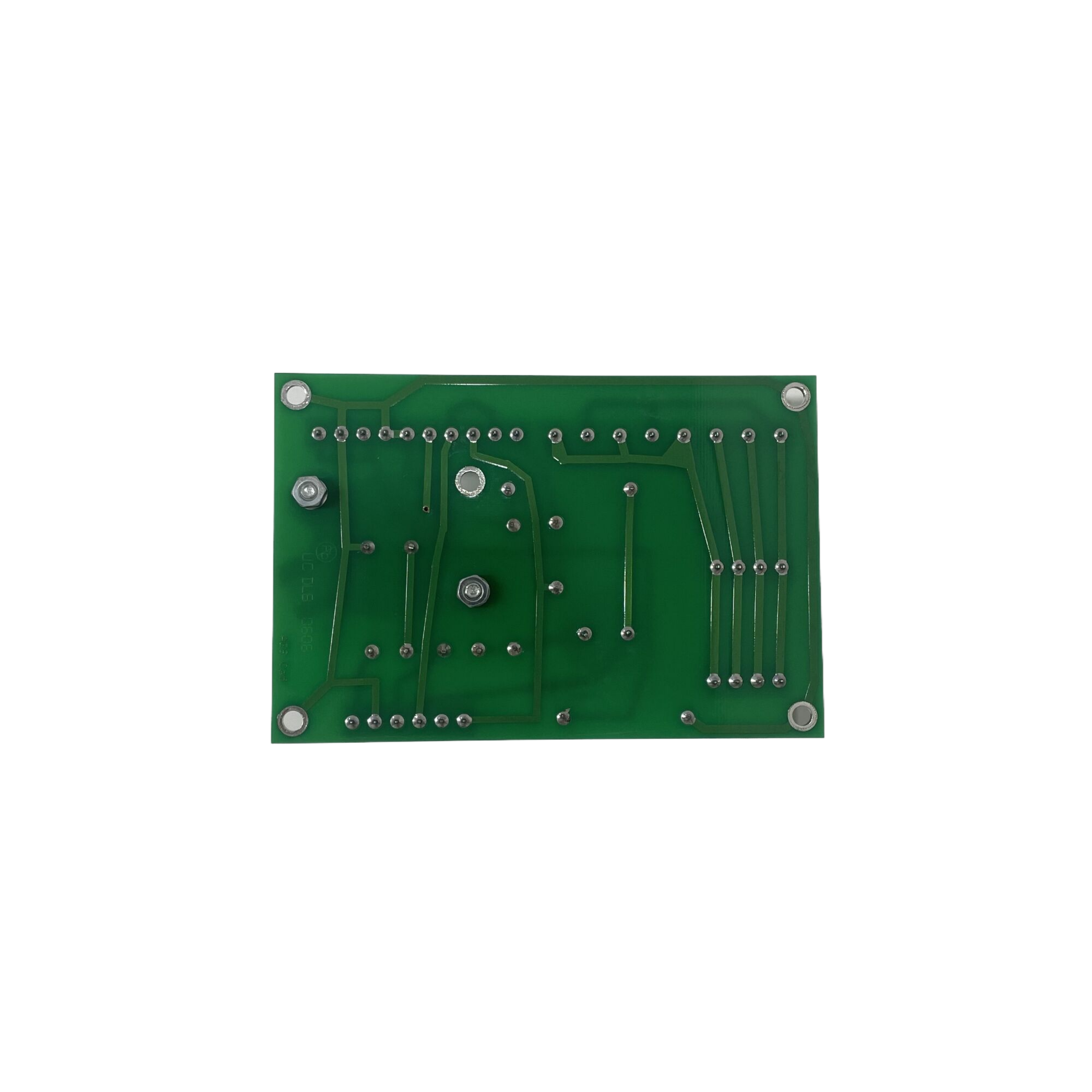

ABB FENA-21 - Operator Interface: Advanced Control Solution for Industrial Applications

ABB FENA-21 - Operator Interface: Advanced Control Solution for Industrial Applications

Introducing the ABB FENA-21: Elevating Automation with Precision and Versatility

In the ever-evolving landscape of industrial automation, the ABB FENA-21 stands out as a pivotal solution for enhancing operational efficiency and reliability. As one of ABB's premier automation products, the FENA-21 combines cutting-edge technology with robust features to meet the diverse needs of modern industries. This product description will delve into the key technical features of the FENA-21, explore its usage scenarios, compare it with other models, and reference related ABB products that complement its capabilities.

Key Technical Features

At the heart of the ABB FENA-21 is its advanced functionality designed for seamless integration into various automation systems. Key features of the FENA-21 include:

1. **High Performance**: The FENA-21 delivers exceptional processing power, ensuring rapid data handling and real-time performance. This is crucial for applications where speed and accuracy are paramount.

2. **Versatile Connectivity**: With multiple communication protocols, including Ethernet/IP, Modbus TCP, and CANopen, the FENA-21 allows for flexible integration into existing networks, facilitating communication between various components of an automation system.

3. **Robust Design**: Engineered to withstand harsh industrial environments, the FENA-21 features a rugged housing that is resistant to dust, moisture, and temperature fluctuations, making it ideal for a wide range of applications.

4. **Scalability**: The FENA-21 is designed with scalability in mind, allowing users to expand their automation systems easily. This is particularly valuable for businesses looking to grow their operations without overhauling their existing infrastructure.

5. **User-Friendly Interface**: The intuitive user interface simplifies configuration and monitoring, making it accessible for operators at all skill levels. This ease of use reduces training time and accelerates deployment.

Usage Scenarios

The ABB FENA-21 is brilliantly suited for a variety of applications across different industries. Its versatility makes it an excellent choice for:

1. **Manufacturing**: In production lines, the FENA-21 can be used to optimize machinery performance, monitor process variables, and ensure quality control through real-time data analytics.

2. **Energy Management**: The FENA-21 can monitor and control energy consumption in facilities, contributing to sustainability efforts while reducing operational costs.

3. **Water Treatment**: In water and wastewater treatment plants, the FENA-21 aids in process automation, ensuring compliance with regulatory standards and enhancing operational efficiency.

4. **Logistics and Warehousing**: The FENA-21 can streamline logistics operations by automating inventory management and tracking systems, leading to improved accuracy and reduced labor costs.

5. **Building Automation**: The FENA-21 is perfect for managing HVAC systems, lighting, and security applications in commercial buildings, contributing to enhanced comfort and energy savings.

Comparison with Other Models

When comparing the ABB FENA-21 to other models in the ABB product lineup, such as the ABB TU841 and ABB PM511V16, several distinctions arise.

- **ABB TU841**: The TU841 is primarily focused on I/O modules within the S800 platform, providing essential connectivity for field devices. While it excels in I/O management, it lacks the advanced data processing capabilities that the FENA-21 offers, making the FENA-21 more suitable for complex automation tasks.

- **ABB PM511V16**: This model is designed for power monitoring and control, providing vital insights into energy usage. However, the FENA-21's versatility in handling various protocols and its broader applications give it an edge in multi-faceted automation environments.

- **ABB SDCS-PIN-51**: This model is tailored for specific control applications, but the FENA-21 outperforms it with its user-friendly interface and superior scalability, allowing it to adapt to changing operational needs.

By offering enhanced processing power, robust design, and versatile connectivity, the ABB FENA-21 positions itself as a superior choice for businesses looking to optimize their automation systems.

Related Models

For those interested in expanding their ABB automation products portfolio, consider the following related models:

1. **ABB UNS1860B-P**: A reliable model for control systems, offering excellent integration capabilities.

2. **ABB PPE100A**: Designed for protection and monitoring applications, ensuring system reliability.

3. **ABB TU852**: A versatile I/O module that complements the capabilities of the FENA-21.

4. **ABB 3HAC16035-1**: Offers advanced control functionalities for demanding applications.

5. **ABB YPM106E**: Ideal for robot control, providing high-level automation features.

6. **ABB 07DC91**: A dependable controller that can be integrated into various automation systems.

7. **ABB GINT5611C**: A model focused on industrial network communication, enhancing connectivity.

8. **ABB 3HAC022436-001**: Tailored for specific control tasks, ensuring efficient operation.

9. **ABB IRB 2600**: A robust industrial robot that works harmoniously with the FENA-21 in manufacturing environments.

10. **ABB ACS880-01-246A-3**: A variable frequency drive that complements the FENA-21 in energy management applications.

Conclusion

In summary, the ABB FENA-21 is a powerful and versatile addition to the ABB automation products lineup. Its high-performance capabilities, extensive connectivity options, and robust design make it an ideal choice for a wide range of industrial applications. Whether you're involved in manufacturing, energy management, water treatment, or building automation, the FENA-21 provides the reliability and efficiency needed to stay competitive in today’s fast-paced market.

Choose the ABB FENA-21 and experience how it can transform your operations, enhance productivity, and pave the way for future advancements in automation technology.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information