K-WANG

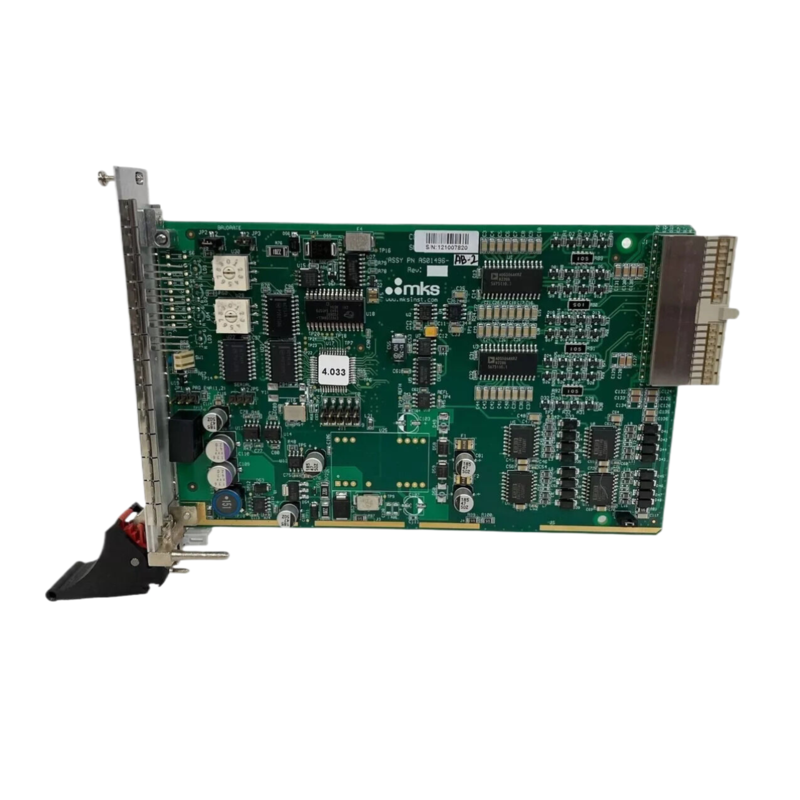

Applied Materials 0010-13650 - AMAT AC BOX, HTESC, P1

The Applied Materials 0010-13650 is a high-performance automation component engineered to meet the rigorous demands of the power industry, petrochemical plants, and general automation environments. Designed with precision and reliability at its core, this model supports seamless integration with complex systems, delivering robust input/output capacity, exceptional durability, and unmatched operational efficiency.

At the heart of the Applied Materials 0010-13650 lies a versatile input/output architecture capable of handling high throughput signals with minimal latency. This ensures that critical data and control commands are processed in real time, a necessity for industries where timing and accuracy directly impact safety and productivity. The unit boasts an input capacity optimized to support multiple simultaneous signal streams, while its output channels maintain high fidelity and noise immunity, making it ideal for automated control loops in harsh industrial settings.

Durability is another key feature of the 0010-13650. Constructed with industrial-grade materials and designed to withstand extreme temperature variations, vibration, and exposure to corrosive agents commonly found in petrochemical and power generation facilities, this model delivers consistent performance over extended operational cycles. The resilience of the Applied Materials 0010-13650 translates into reduced downtime and lower maintenance costs, critical factors for maintaining uptime in mission-critical automation processes.

Performance metrics for the 0010-13650 include rapid response times, high signal integrity, and compatibility with a broad range of control systems and communication protocols. This adaptability ensures that it can be integrated effortlessly into existing infrastructures or newly designed automation lines without extensive customization.

In practical applications, the Applied Materials 0010-13650 excels in scenarios such as controlling power distribution networks, monitoring and regulating chemical processing units, and automating general manufacturing lines where precision and reliability are paramount. For instance, in the power industry, the 0010-13650 provides real-time feedback and control for substations and generation plants, enabling operators to optimize load balancing and prevent outages. In petrochemical plants, it manages complex sensor arrays and actuator controls that maintain safety and efficiency during volatile chemical reactions. Within general automation contexts, its robust I/O capabilities support assembly line robotics and process monitoring systems, ensuring smooth, uninterrupted production.

When compared to other Applied Materials automation products, the 0010-13650 stands out due to its superior input/output scalability and enhanced durability features. While models like the Applied Materials 0010-20138 and Applied Materials 0010-09341 offer reliable automation solutions, the 0010-13650 provides a broader operational temperature range and higher resistance to environmental stressors. Additionally, the Applied Materials 0190-09459 and Applied Materials 0041-12156 models serve complementary roles in signal processing and interface management; however, the 0010-13650 integrates these functionalities into a single, more streamlined package, reducing complexity and improving system coherence.

Alongside the Applied Materials 0010-13650, we also offer the Applied Materials 0190-34929-000 and Applied Materials 0090-03867, which enhance system diagnostics and enable advanced communication protocols, respectively. The Applied Materials 0242-70220 and Applied Materials 0190-09454 are ideal for expanding input channel capacity and improving signal conditioning, making them excellent partners in complex automation setups. For high-precision applications, the Applied Materials 0040-08376 and Applied Materials 0010-70001 provide enhanced sensor interfacing and modular scalability. Additionally, the Applied Materials 0010-23684 REV 003 and Applied Materials 0010-77825 offer specialized control functions that complement the core capabilities of the 0010-13650.

The application of 0010-13650 in power industry, petrochemical, and general automation is further bolstered by its compatibility with a wide array of industrial standards and protocols, ensuring it can be deployed without extensive reconfiguration. This makes it an attractive choice for upgrading legacy systems or implementing new automation frameworks where reliability and performance are non-negotiable.

In summary, the Applied Materials 0010-13650 is a top-tier automation product that delivers exceptional input/output capacity, rugged durability, and flexible performance tailored for demanding industrial environments. Its unique advantages over other Applied Materials models, combined with seamless integration capabilities, make it a cornerstone solution for power industry operations, petrochemical processing, and general automation tasks. For those seeking robust and reliable automation products, the 0010-13650 represents a strategic investment in operational excellence and long-term system stability.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923