K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

Redundant Coax

Estimated Shipping Size

Dimensions: 5.0" x 4.0" x 6.0"

(12.7 cm x 10.2 cm x 15.2 cm)

Weight: 0 lbs 15.0 oz (0.4kg )

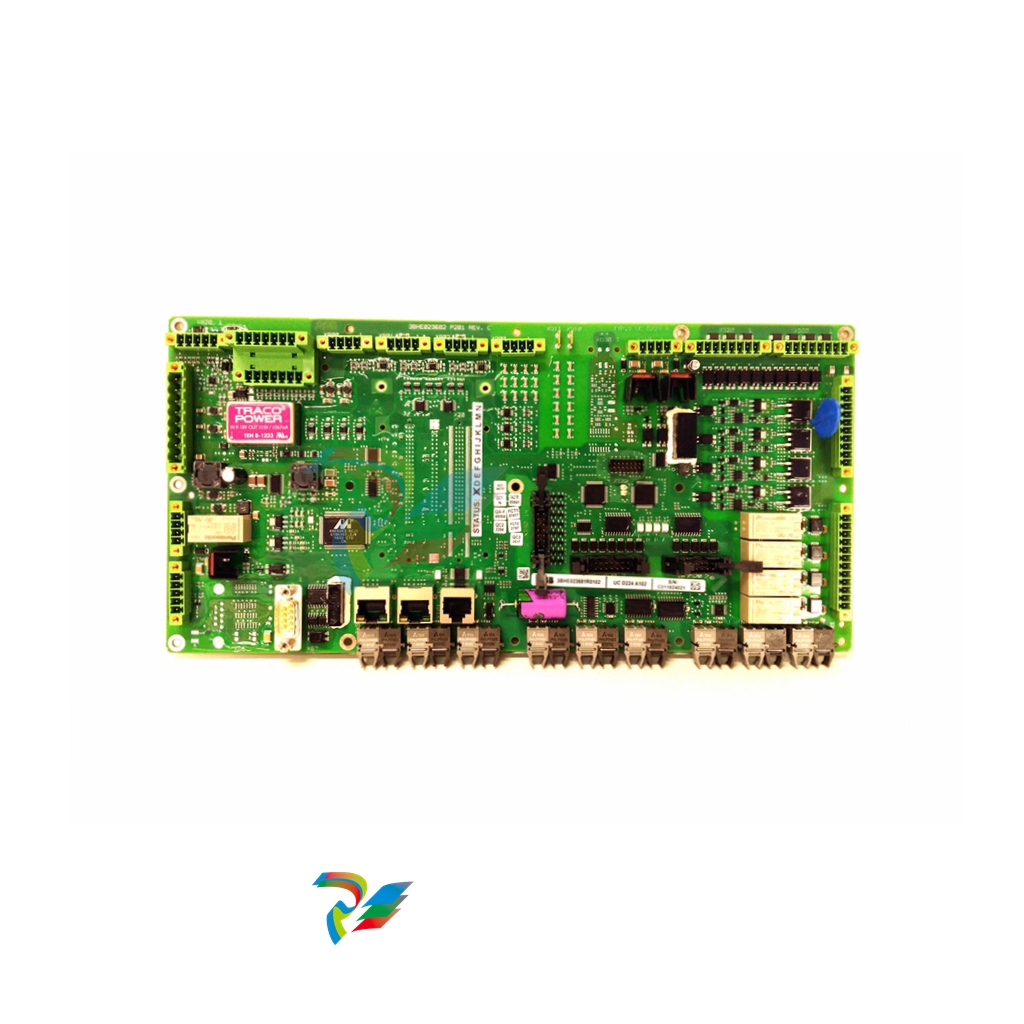

ABB GATS110112R0011 PDnet Coupler Module

Basic information

Model No.: GATS110112R0011, this model number is the unique identification of this specific PDnet Coupler Module in ABB's product range, which is used to accurately distinguish between different product configurations, versions and other details.

System: Typically compatible with industrial automation control systems such as ABB's Advant Controller 31, it is a key component of the system's network architecture, enabling efficient data communication and signal coupling between different devices or subsystems within the system.

Functionality

Network coupling function: As a coupler in the PDnet network, its core function is to realise the effective connection and transmission of signals in the network. It can integrate and convert signals from multiple devices or nodes to ensure accurate and error-free data transmission in the network, thus establishing a complete and stable industrial automation network architecture and achieving seamless interconnection between devices.

Communication protocol support: It supports a variety of common data communication protocols and signal types, and can be perfectly interfaced with various types of PLCs, controllers, remote I/O modules and other devices of ABB to achieve high-speed and stable data exchange. This compatibility makes it able to meet the complex and diverse equipment communication needs of industrial sites and ensure the coordinated operation of the entire system.

Signal isolation and enhancement: With excellent electrical isolation performance, it can effectively prevent electrical interference and signal distortion between different devices, greatly improving the stability and reliability of the system. At the same time, the module can also be appropriate signal enhancement and conditioning, to ensure that the signal in long-distance transmission or complex electromagnetic environment can still maintain good quality, reduce signal attenuation and BER.

Flexible Configuration: With a high degree of configuration flexibility, users can easily adjust its communication parameters, coupling mode, etc. according to specific application scenarios and system requirements, through software or hardware configuration, to adapt to different network topologies and communication needs, convenient for system integration and subsequent expansion and upgrading.

Technical Parameters

Communication interfaces: Equipped with communication interfaces in line with PDnet network standards, common optical fibre interfaces, twisted-pair interfaces, etc., to meet different network wiring requirements and adapt to different communication distance requirements. These communication interfaces have high transmission rate and strong anti-jamming ability, which can support high-speed data transmission and real-time control applications to ensure rapid response and stable operation of the system.

Transmission rate: support for high data transmission rates, generally up to several megabits per second or even higher, the specific transmission rate will vary according to different configurations and application scenarios. High transmission rate can fully meet the strict requirements of industrial automation systems for rapid transmission of large amounts of data to ensure that the system is real-time and efficient.

Isolation voltage level: with a clear and high isolation voltage level, it can withstand a certain range of high voltage shocks, effectively isolate equipment and circuits with different potentials, prevent the propagation and spread of electrical faults in the system, and ensure the electrical safety of the system. Its isolation voltage level is usually based on the actual electrical environment and safety requirements of the industrial site is carefully designed, generally up to thousands of volts or even higher.

Operating temperature range: can adapt to a wide range of operating temperatures, generally - 20 ℃ to + 60 ℃ or even wider, can be in a variety of harsh industrial environments and stable work, whether it is cold outdoors or high temperature industrial plant, can ensure the normal operation of the module, so as to ensure the reliability and stability of the entire system.

Application Areas

Industrial automation production line: In the automation production line, the coupler module can be used to connect production equipment, robots, sensors, controllers and other key components to achieve the automation control of the production process and data acquisition. Through it, each device can share production data and control instructions in real time, and complete complex production tasks together, significantly improving production efficiency and product quality.

Process control system: In the process control field of chemical, pharmaceutical, food and beverage, GATS110112R0011 PDnet Coupler Module can be used to build the network architecture of process control system and realise real-time monitoring and precise control of important parameters such as temperature, pressure, flow rate, liquid level and other important parameters in the production process. It can closely connect different field instruments, controllers and host computer systems together to ensure stable operation of the production process and consistency of product quality.

Intelligent building system: In the equipment monitoring system of intelligent buildings, such as HVAC system, lighting system, lift system, etc., this module can be used to achieve communication and integration between different sub-systems. With the help of it, the controllers of each sub-system can be connected to a unified network platform to achieve centralised management and monitoring of various equipment in the building, improve the level of building intelligence and energy efficiency, and create a more comfortable, convenient and energy-saving building environment for users.

Transportation system: In the field of transportation such as rail transportation and port automation, it can be used for communication and coupling between vehicle control system, signal system, port equipment control system and so on. It can ensure accurate information interaction and cooperative work between different equipment and systems, and plays an important role in guaranteeing the safe and efficient operation of transport.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923