K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

The VersaMax IP is very robust and meets the IEC protection level IP67 (based on the IEC60529 standard). available

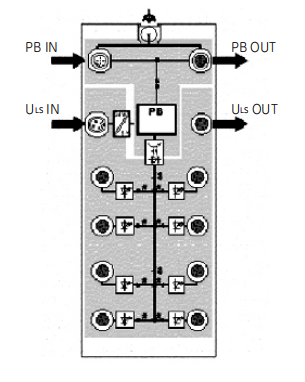

VersaMax IP products do not require a sealed casing in oil-water environments. Each module can be accessed through Profibus DP

The interface communicates with the Profibus DP network controlled by PLC or PC.

GE FANUC IC676PBI008 Positive logic input

Characteristics of VersaMax IP

No need to seal the casing, saving installation costs

No need for chassis and DIN rail

Each module can serve as an independent I/O station

The module communicates at a speed of 12M baud rate on the Profibus DP network

The address of the module is set by two rotary switches

The module has 8 or 16 inputs, 8 outputs, or mixed I/O (4 inputs and 4 outputs)

• Devices can be directly connected to sensors and control devices through various quick connect plugs

• Can input PNP type three wire sensor, 2-wire DC sensor or dry contact signal

• Output short circuit and overload protection

Multiple diagnostic LEDs can clearly indicate the status of power, communication, and points

general provisions

Bus power supply 18-30VDC

Internal current consumption 100mA (maximum)

Input cable length less than 100 meters

Input switching current ON 5mA

Input delay time 3.1ms

Standard NEMA4, IEC60529, IP67

Operating temperature -25 ℃ -60 ℃

Storage temperature -25 ℃ -85 ℃

Operating/Storage Humidity 95%

Wiring methods 2-, 3-, and 4-wire systems

Bus connector M12 connector head

Input connector M12 connector head

Switch input module (IP67)

The module can be directly connected to the Profibus DP bus, which provides switch inputs for connecting PNP3 line sensors.

Each input has a short-circuit protection function, with a yellow and a red LED indicating ON or overload status.

The module is encapsulated with epoxy resin and uses metal connectors, making it very sturdy.

The module is connected to the Profibus DP bus through an M12 connector. One green and one red indicator light indicate the online/offline status of the module, and the module supports up to

The communication rate of the module automatically matches the communication rate of the main station at 12Mbps. The module address can be set through two rotary switches, which can be set

From 0 to 99.

The power supply is connected through a 4-pin M12 connector. The green power LED indicates that the module is powered normally.

In order to configure the module software, a GSD file is attached to the module.

Recommended cable connectors:

Profibus:IC676ACC004、IC676ACC005

Characteristics of switch input module

The input of the switch quantity is used to connect the PNP 3-wire sensor

• Input short-circuit protection function

Automatic detection of communication speed

M12 connectors are used for bus and input connections

M12 connector is used for power connection

Compliant with NEMA4, VDE0106 standards and IEC protection level IP67

• Maximum communication speed of 12 Mbps

Input module characteristics

IC676PBI008

8 inputs, DC

Supply voltage

Module power supply 18-30 VDC

Internal current consumption<100 mA (from bus power supply)

Input circuit (8) PNP 3-wire sensor

Input voltage 24 VDC standard

Input current of 5 mA per channel, short circuit protection

Input delay ON: 3.1 ms

OFF:4.1 ms

Connector

Auxiliary power supply 4-pin M12 connector

Bus M12 connector, anti loosening

Input M12 connector

set up

Address 0-99 (decimal) is controlled by two rotary switches

LED indicator

Bus green/red: normal operation/no communication

Power green/red: normal operation/bus power failure

Input status yellow: Input ON

Shell 60 x 160 x 44.5 (W x H x D)

Protection level NEMA4, IP 67

Working temperature -25 ° C to+60 ° C

Working humidity 95%

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923