K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

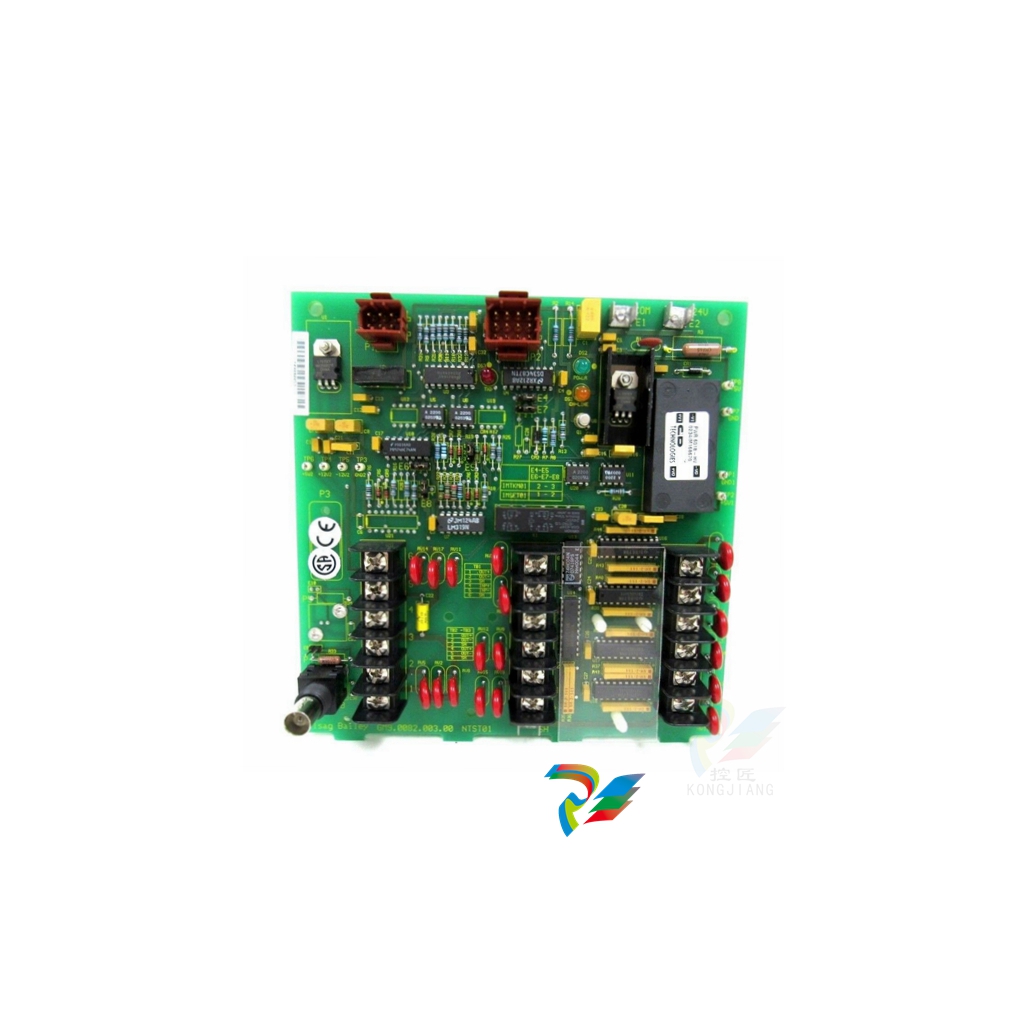

ABB PMM 24 Mass Storage Unit PMM 24 H&B Contronic

Functional Features

Large-capacity storage: With a large storage capacity, it can meet the storage needs of H&B Contronic system for a large amount of data during operation, such as system configuration files, historical operation data, fault records, program codes, etc., which is convenient for users to call and view at any time.

Fast data read/write speed: Adopting advanced storage technology and interface design, it has fast data read/write speed, which can quickly store the data generated by the system into the unit, and also read the data quickly for system processing when needed, thus improving the overall operation efficiency of the system.

High data reliability: Equipped with data verification and error correction mechanisms, it can automatically detect and correct errors during data storage and reading to ensure data integrity and accuracy. At the same time, it may also have data redundancy function to prevent data loss by backing up data.

Strong compatibility: It has good compatibility with other devices and modules in the H&B Contronic system, and can be seamlessly integrated into the system to realize data interaction and sharing with other devices.

Technical Parameters

Storage capacity: Different capacity specifications are usually available, and common storage capacities may range from a few hundred megabytes to several gigabytes to meet the needs of different users and application scenarios.

Interface type: Standard industrial storage interfaces such as SCSI, IDE or other specialized interfaces may be used to ensure reliable data transfer with other devices in the system.

Data Transfer Rate: The data transfer rate is high, for example, the transfer rate of the SCSI interface may reach tens of megabytes per second or even higher, in order to meet the system's requirements for data reading and writing speed.

Operating temperature range: generally able to work normally in a wide temperature range, such as - 20 ℃ to + 70 ℃, to adapt to different industrial environment temperature conditions.

Application Scenarios

Industrial automation control system: In the automated production line, it can be used to store the operating parameters of the production equipment, process formulas, and quality inspection data. When the system needs to adjust the production process or carry out equipment maintenance, it can quickly obtain relevant data from the storage unit to improve production efficiency and product quality.

Energy management system: In the control system of power, petroleum, chemical and other energy industries, it can store a large amount of data in the process of energy production, transmission and distribution, such as power generation, power consumption, flow rate, pressure and other parameters, providing data support for energy management and optimization.

Process control system: In chemical, pharmaceutical, food and other process industries, it can store key parameters and historical data in the production process, such as reaction temperature, pressure, liquid level and so on. Through the analysis and processing of these data, precise control and optimization of the production process can be achieved.

Traffic monitoring system: In the intelligent transportation system, it can be used to store traffic flow data, vehicle speed, violation records and other information. These data have important reference value for traffic management and planning, which can help the traffic department to optimize traffic signal control, road planning and so on.

FEATURES

• Process Station with integrated fieldbus capability

• 4 high-speed fieldbus lines

• Supports different fieldbus types, even simultaneously: PROFIBUS-DP, up to 12 MBd Modbus CAN Foundation Fieldbus H1 (with LD800 HSE)

• Easy engineering: fully integrated in Control Builder F

• One unified database for field devices shared by the control level and the Human System Interface (HSI)

• Module recognition with factory and operational parameters

• Comprehensive diagnostics for proactive maintenance

• Compact, rugged design

• Front panel connectors

• DIN Rail (C-rail) or wall mounting for easy installation

• Ambient temperature 0-60 °C (32-140 °F) with temperature monitoring

• EMC certification according to EN50082

• Certification: CE, NAMUR, CSA, UL, EN61000-6-2.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923