K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

ABB H&B Contronic Drive Module SL 04 H&B Contronic

Basic Information

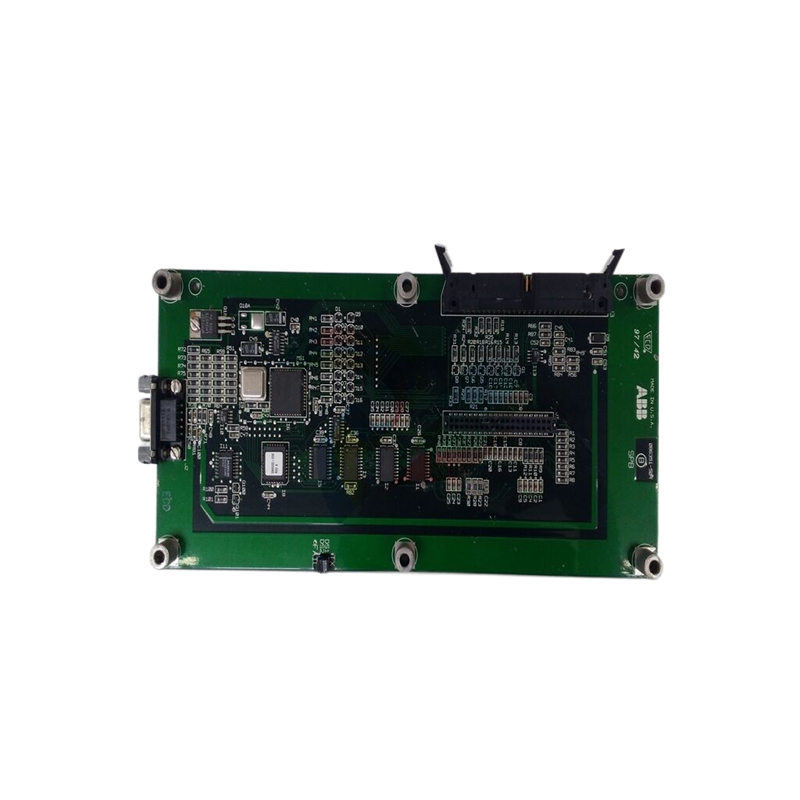

Appearance and construction

ABB H&B Contronic SL04 drive modules are usually compact and rectangular in shape. The enclosure is made of metal or high-quality engineering plastics, which not only provide good mechanical protection against physical damage to the internal components, but also provide excellent electromagnetic shielding to reduce the effect of external electromagnetic interference on the internal circuitry of the module.

On the surface of the module, there are clear and eye-catching markings, including ‘SL04’ and ‘ABB H&B Contronic’, which make it easy for users to quickly identify the module during installation, maintenance and troubleshooting. It is sized for easy installation in control cabinets and is likely to support standard DIN rail mounting, which saves space and facilitates system expansion and maintenance.

Weight Information

Although the specific weight data may vary depending on the specific configuration and component differences, but from the general characteristics of industrial modules, it is assumed that the weight should be moderate, will not cause excessive burden on the mounting bracket, etc., and to ensure the stability of the working condition.

Technical Parameters

Power requirements

The drive module usually requires a specific power supply. Generally, it may be supplied by 24V DC (direct current) power supply, and can adapt to a certain range of voltage fluctuations, for example, between 20 - 30V DC, in order to ensure that in the industrial field power supply may be unstable, the module can still be able to work normally, to maintain stable drive function.

Input and output characteristics

Input signals: A variety of input channels are available, including digital and analogue inputs. The digital input channel can receive digital signals from external devices (e.g. sensors, controllers, etc.), which may be switching signals indicating the state of the device, such as 0V or 24V for the on/off state. Analogue input channels can receive continuously changing analogue signals from sensors such as temperature, pressure, speed, etc. Common signal ranges may be standard industrial analogue signals such as 0 - 10V or 4 - 20mA.

Output signals: On the output side, they are mainly used to drive devices such as motors, and are able to output appropriate voltage and current signals to control the motor's speed, steering and other operating states. The output parameters such as power and torque can be adjusted according to the actual motor load and control requirements to ensure that the motor can be effectively driven under different working conditions.

Communication Interface

SL04 drive module supports a variety of industrial communication protocols, which is the key to achieve its co-operation in the automation system. It may support Profibus, Modbus, Industrial Ethernet and other communication protocols. Through these communication interfaces, the module can exchange data and communicate with other ABB devices (such as PLC, HMI, etc.) and third-party industrial devices, so as to realise functions such as remote monitoring of the drive process, parameter setting and fault diagnosis.

Functional features

Drive control functions

As a drive module, its core function is to precisely control the operation of motors and other devices. It can accurately adjust the size and frequency of output voltage and current according to the input control signals, such as speed setting value, steering instruction, etc., through internal control algorithms (such as vector control, direct torque control and other advanced control strategies), so as to realise the precise control of the motor's speed and torque. This kind of precise control is very important in industrial applications, such as in the scenarios of conveyor belt motor control in automated production lines and spindle motor control in machine tools, etc., to ensure the stable operation of the equipment in accordance with the predefined process requirements.

Protection Functions

A variety of protection mechanisms are built-in to ensure the safety of the module itself and the equipment it drives. For example, with overcurrent protection, when the output current exceeds the set safety threshold, the module will automatically take measures, such as reducing the output power or cutting off the output, to prevent damage to the motor and other equipment due to overcurrent. At the same time, there are over-voltage protection, overheating protection and other functions, real-time monitoring of the module's internal voltage and temperature, once an abnormal rise in the situation, timely protection action. These protection functions can effectively extend the service life of the equipment and reduce the downtime caused by failure.

In addition, the module can also monitor and protect the motor driven by the blocking, overload and other abnormal conditions. When the motor is blocked or overloaded, it can quickly detect and take corresponding protective measures, such as issuing an alarm signal and stopping the drive to avoid further damage to the motor and drive module.

Diagnosis and alarm function

With powerful self-diagnosis function, it can monitor its own working status and operating parameters in real time. It can detect whether the power supply voltage is normal, whether there is any signal abnormality in the input and output channels, whether the communication is smooth, and the working status of the key internal components. Once any abnormality is detected, it will send the fault information to the upper computer (e.g. monitoring system, PLC, etc.) through the communication interface, and at the same time, it will send out intuitive alarm signals locally through the indicator or buzzer, etc., which is convenient for the maintenance personnel to locate and eliminate the faults quickly. This diagnostic and alarm function helps to improve the reliability and maintainability of the system and reduce the impact of equipment failure on production.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923