K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

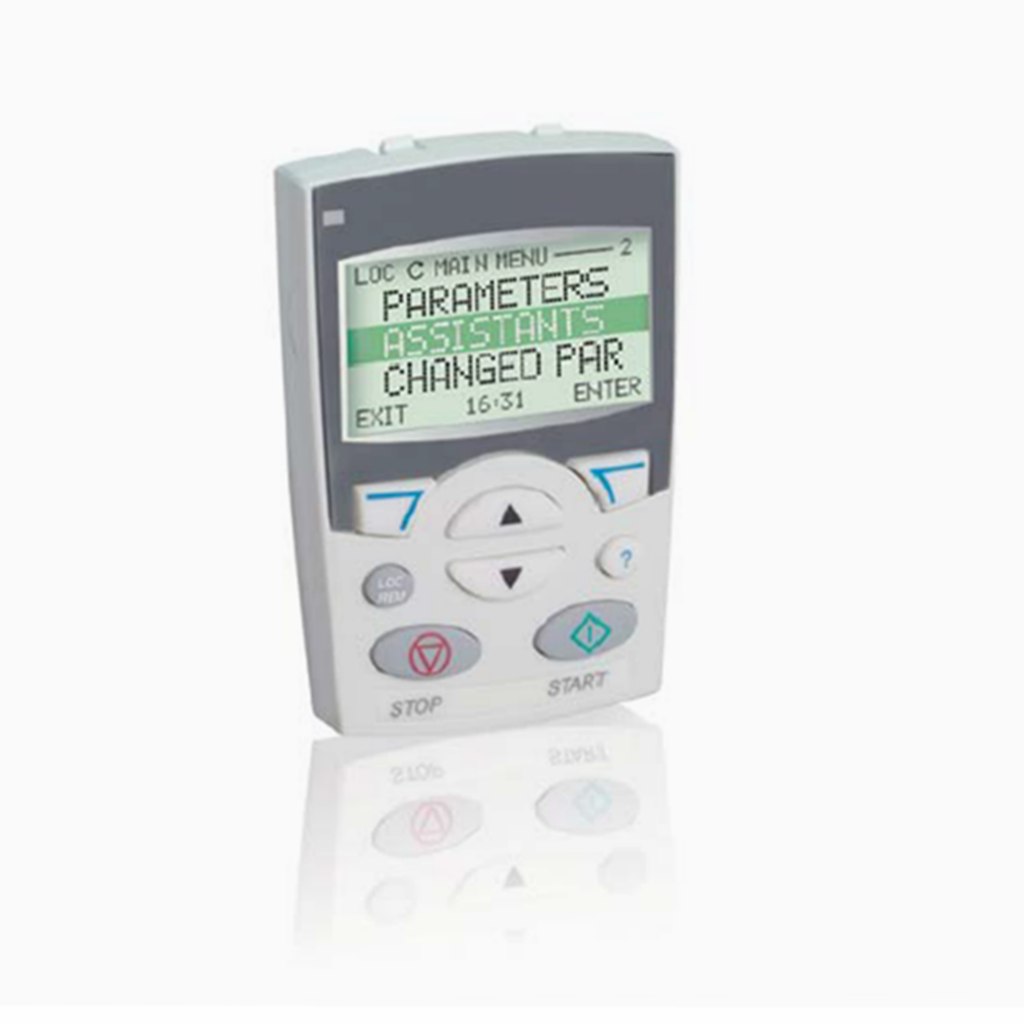

ABB H&B Contronic XU 14 Module XU 14 H&B Contronic

Functional Characteristics

Data processing and arithmetic: It can quickly collect and process all kinds of input industrial field data, such as temperature, pressure, flow and other analogue signals as well as switching signals. A variety of mathematical operations and logical judgments can be performed, such as four operations, comparison operations, logic and non-operations, etc., and the collected data can be analysed and processed according to the preset procedures and algorithms to meet different control requirements.

Control function: It can output control signals to precisely control the equipment on the industrial site, such as the starting and stopping of motors, the opening adjustment of valves, and the frequency setting of inverters. The control output signal has high precision and stability, which can ensure the stable operation and precise control of the equipment.

Communication capability: It supports a variety of communication protocols, such as Profibus, Modbus, CANopen, etc., which can conveniently communicate and exchange data with other devices to achieve system integration and cooperative work. Through the communication interface, it can be connected with PLC, DCS, human-machine interface and other devices to form a distributed control system.

Technical Parameters

Power supply voltage: the general working voltage range between DC20V and DC30V, some special application scenarios may be different models, with a certain adaptability to voltage fluctuations, usually allow voltage fluctuations in the range of ±10% or so.

Number of input/output points: There are several digital input/output points and analogue input/output points, the number of digital input/output points generally ranges from 8 to 32, and the number of analogue input/output points generally ranges from 4 to 8, which can be selected according to the specific model and application requirements.

Input and output signal type: digital input signal is usually DC24V level signal, digital output signal can be relay output, transistor output or thyristor output, etc., which can drive different types of loads. Analogue input signal is usually 0mA to 20mA, 4mA to 20mA current signal or 0V to 10V, -10V to +10V voltage signal, analogue output signal is usually 0mA to 20mA, 4mA to 20mA current signal or 0V to 10V voltage signal.

Communication interface: usually equipped with standard communication interface, such as RS485, RS232, Ethernet interface, etc., the communication rate varies according to different communication protocols and application requirements, such as Profibus communication rate of up to 12Mbps, Modbus communication rate of up to 115200bps and so on.

Application Scenario

Manufacturing automated production line: In automated production lines of automobile manufacturing, machining, electronic equipment manufacturing and other industries, it can be used to control the operation of production equipment, monitor the parameters and status of the production process, such as controlling the movement of robots, monitoring the temperature and pressure of equipment, etc., to achieve the automation and intelligence of the production process.

Energy management system: In the monitoring system of power, oil, natural gas and other energy industries, it can be used to collect and process various data in the process of energy production, transmission and distribution, such as power generation, power consumption, flow rate, pressure, etc., to achieve real-time monitoring and optimisation management of the energy system.

Intelligent Building Automation System: In the HVAC system, lighting system, lift system, etc. of intelligent buildings, it can be used to realise automated control of equipment and energy-saving management, such as automatically adjusting the operation of air-conditioning and lighting equipment according to the indoor temperature and light intensity, so as to improve the building's energy use efficiency and comfort.

Water treatment and environmental protection system: In water treatment and environmental protection systems such as sewage treatment plants, water plants, waste gas treatment facilities, etc., it can be used to monitor and control the operation of water treatment equipment and environmental protection equipment, such as controlling the operation of pumps, fans, valves, and other equipment, to ensure that the water treatment and environmental protection process is efficient and stable.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923