K-WANG

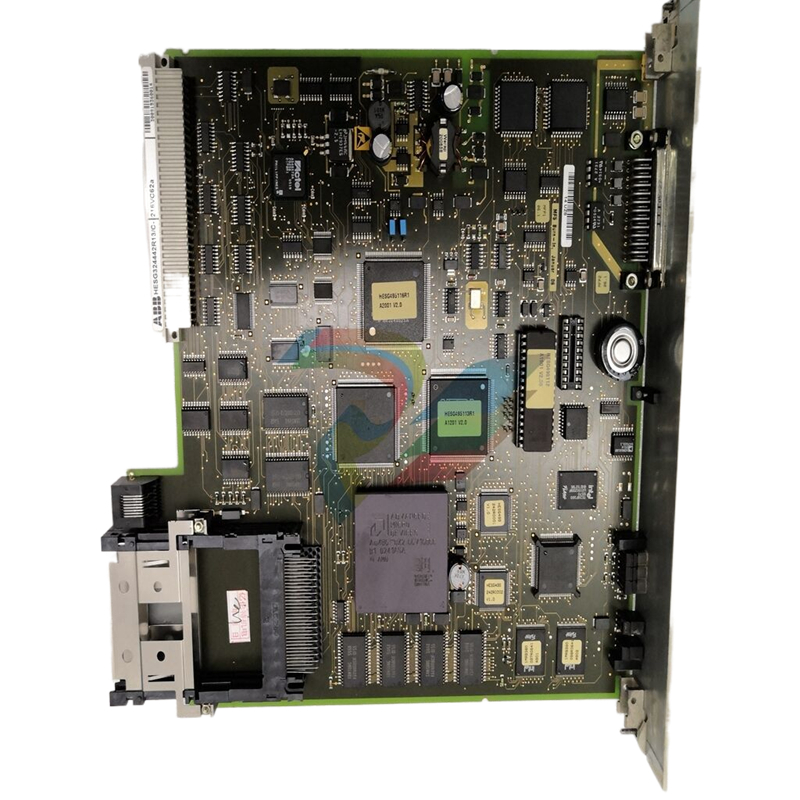

ABB DO810 3BSE008510R1 - Digital Output Module

The ABB DO810 3BSE008510R1 is a highly robust and versatile automation module designed to meet the demanding requirements of the power industry, petrochemical plants, and general automation environments. Engineered for superior reliability and precision, the DO810 delivers exceptional input/output (I/O) capacity and operational durability, positioning it as a critical component in complex control systems.

At the core of the ABB DO810 3BSE008510R1’s technical excellence lies its advanced digital input/output handling capability. The unit supports a wide range of signal types, providing seamless integration with field devices and control units. Its input channels are optimized for high-speed signal processing, ensuring rapid response times essential for safety and process control applications. The output channels maintain precise actuation control with minimal latency, enabling real-time adjustments critical in petrochemical processing and power grid management. Durability is ensured through a rugged construction that withstands harsh industrial conditions, including extreme temperatures, vibration, and electromagnetic interference, making it suitable for continuous operation in demanding environments.

Performance metrics for the DO810 3BSE008510R1 reveal an operational lifecycle that exceeds industry standards, supported by ABB’s quality assurance and stringent testing protocols. This module’s low failure rate and high mean time between failures (MTBF) significantly reduce downtime and maintenance costs, offering operators enhanced system availability. The module’s compatibility with ABB’s automation ecosystem further optimizes performance by enabling streamlined communication with other control devices and software platforms.

In real-world applications, the ABB DO810 3BSE008510R1 shines in scenarios requiring reliable, fast, and accurate automation control. In the power industry, it is widely used in substations and power generation facilities for monitoring and controlling circuit breakers, transformers, and protection relays. Its high-speed I/O capabilities facilitate swift fault detection and isolation, minimizing outage durations and protecting critical infrastructure. Within petrochemical plants, the DO810 handles complex process automation tasks, such as valve position monitoring, emergency shutdown systems, and hazardous area control, where fail-safe operation is non-negotiable. For general automation, the module adapts to diverse industrial processes, from manufacturing line automation to building management systems, ensuring precise and consistent control outcomes.

When compared to other ABB automation products, the DO810 3BSE008510R1 offers a unique blend of scalability and ruggedness. Unlike the ABB DSBC176 3BSE019216R1, which focuses primarily on analog signal conditioning, the DO810 excels in digital I/O operations, delivering greater flexibility in mixed-signal environments. Compared to ABB CB801 3BSE042245R1, a communication interface module, the DO810 provides more direct control over field devices rather than serving solely as a data conduit. Additionally, while ABB PFTL201C 3BSE007913R50 50KN is specialized in force measurement applications, the DO810 offers broader applicability across various control tasks without compromising precision. This makes the DO810 a preferred choice for integrators seeking a reliable and adaptable I/O module.

Alongside the ABB DO810 3BSE008510R1, we also offer complementary models such as the ABB FI820F for signal isolation and filtering, and the ABB PFSK151 3BSE018876R1, which serves as a protective relay interface enhancing system safety. The ABB PPC907BE 3BHE024577R0101 programmable controller pairs seamlessly with the DO810 for advanced logic operations and process control. For enhanced communication capabilities, the ABB DSBC176 3BSE019216R1 and ABB SCYC51010 58052515G provide robust analog and serial communication options, respectively. The ABB RMU811 and ABB UFC092BE01 modules support remote monitoring and control functionalities, expanding the automation ecosystem’s reach. Additionally, ABB’s IMDSO14 interface module complements the DO810 by offering synchronized data acquisition and diagnostics, crucial for predictive maintenance strategies.

The application of the DO810 3BSE008510R1 in power industry, petrochemical, and general automation underscores its essential role in modern industrial control systems. Its dependable performance ensures operators maintain tight control over critical processes, while its integration capabilities streamline system design and implementation. As part of ABB automation products, the DO810 stands out by combining advanced technology with proven durability, supporting the evolving needs of industries that demand reliability, precision, and safety.

In summary, the ABB DO810 3BSE008510R1 offers unmatched digital I/O capacity, rugged construction, and versatile application potential. It is a cornerstone module for industries requiring high-performance automation solutions. When paired with other ABB models such as the FI820F, PFSK151, PPC907BE, and DSBC176, it forms a comprehensive automation platform that addresses complex operational challenges efficiently. For businesses invested in the power sector, petrochemical industry, or general automation, the ABB DO810 3BSE008510R1 represents

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923