K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Description

Introducing the ABB XM06B5: A Cutting-Edge Solution for Industrial Automation

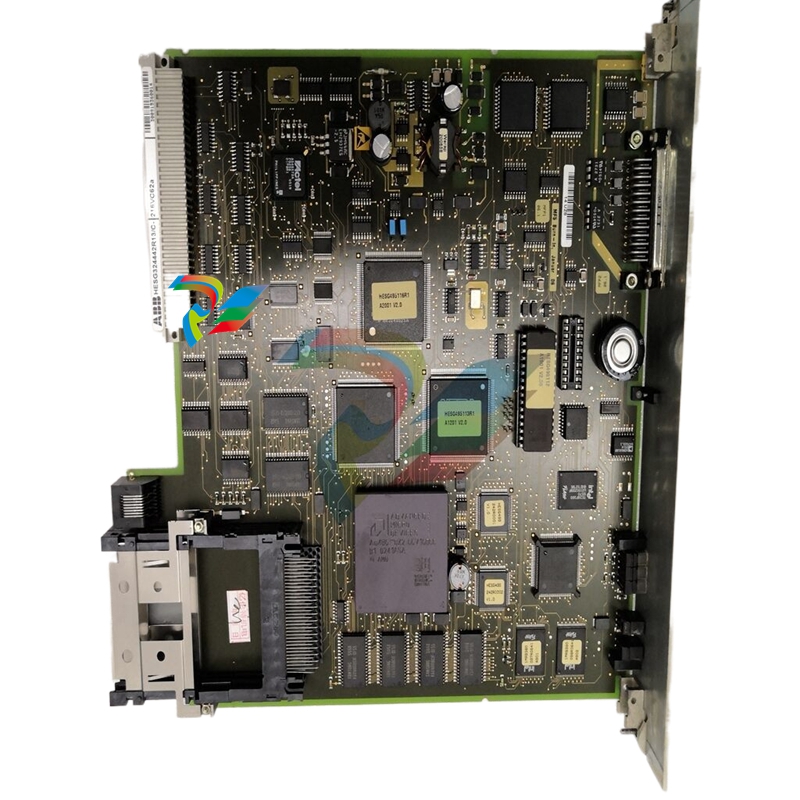

ABB XM06B5 - High-Power Control Module for Industrial Automation, Model Specific, Designed for Precision Control

ABB XM06B5 - High-Power Control Module for Industrial Automation, Model Specific, Designed for Precision Control

Introducing the ABB XM06B5: A Cutting-Edge Solution for Industrial Automation

In a world where industrial efficiency and reliability are paramount, the ABB XM06B5 stands out as a pivotal component of modern automation systems. This advanced device combines innovative technology with robust performance, catering to the diverse needs of industries ranging from manufacturing to energy management. Here’s a comprehensive look at the key technical features, usage scenarios, and how the ABB XM06B5 compares to other models in the ABB family.

Key Technical Features

The ABB XM06B5 is engineered with a suite of features designed to enhance operational efficiency and system integration. Some of its standout specifications include:

1. **High Performance**: The XM06B5 boasts superior processing capabilities, enabling it to handle complex automation tasks with ease. Its powerful CPU ensures swift data processing, making it ideal for real-time applications.

2. **Versatile Communication Protocols**: Equipped with multiple communication interfaces, including Ethernet/IP and Modbus, the ABB XM06B5 seamlessly integrates with various systems and devices. This versatility facilitates interoperability, allowing for efficient data exchange across platforms.

3. **Robust Design**: Built to endure the rigors of industrial environments, the XM06B5 features a rugged housing that is resistant to dust, moisture, and extreme temperatures. This durability ensures long-term reliability and minimizes maintenance needs.

4. **User-Friendly Interface**: The device is designed with an intuitive user interface that simplifies configuration and monitoring. Users can easily navigate through settings and parameters, enhancing usability for technicians and engineers alike.

5. **Scalability**: The ABB XM06B5 supports modular expansions, allowing businesses to scale their automation systems as needed. This flexibility is crucial for adapting to changing production demands and technological advancements.

Usage Scenarios

The ABB XM06B5 is exceptionally versatile, making it suitable for a broad range of industrial applications. Here are a few scenarios where this device can be effectively utilized:

1. **Manufacturing Automation**: In manufacturing settings, the XM06B5 can control robotic arms, conveyor systems, and automated assembly lines, streamlining production processes and reducing labor costs.

2. **Energy Management Systems**: The device plays a critical role in monitoring and controlling energy consumption in facilities. By integrating with smart grid systems, it helps optimize energy usage, leading to significant cost savings.

3. **Process Control**: In chemical or food processing industries, the ABB XM06B5 can manage complex processes by regulating temperature, pressure, and flow rates, ensuring product quality and safety.

4. **Building Automation**: The XM06B5 can be employed in building management systems to control HVAC, lighting, and security systems, contributing to energy efficiency and occupant comfort.

5. **Remote Monitoring**: With its robust communication capabilities, the XM06B5 enables remote monitoring and control of equipment, allowing operators to manage operations from anywhere, thus enhancing responsiveness and minimizing downtime.

Comparison with Other Models

When comparing the ABB XM06B5 to other models within the ABB automation products lineup, several distinctions emerge. For example, while the ABB UNS1860B-P offers extensive I/O capabilities for intricate applications, the XM06B5 focuses on high-speed processing and communication, making it more suitable for dynamic environments.

Similarly, the ABB TU852 S800 I/O excels in distributed control systems, but it may not match the XM06B5's versatility in communication protocols and user interface. In contrast, models like the ABB PM511V16 and ABB SDCS-PIN-51, while robust, often serve more niche applications where the XM06B5's adaptability shines through.

The ABB XM06B5 positions itself as a powerful alternative to models such as the ABB ACS880-01-246A-3, which is renowned for variable frequency drive applications. The XM06B5, however, provides a broader scope for automation solutions, making it an all-encompassing choice for various industries.

Related Models

For those exploring the ABB XM06B5, several related models within the ABB automation products range may also pique interest:

1. **ABB UNS1860B-P**: A robust model known for its extensive I/O capabilities.

2. **ABB TU852 S800 I/O**: Ideal for distributed control systems.

3. **ABB PM511V16**: Focused on advanced process control applications.

4. **ABB ACS880-01-246A-3**: A highly regarded variable frequency drive.

5. **ABB SDCS-PIN-51**: Suited for high-performance applications in industrial automation.

6. **ABB TU841**: A reliable option for field device connectivity.

7. **ABB 3HAC16035-1**: Known for its compact design and easy integration.

8. **ABB DC551-CS31**: Offers superior control capabilities for various applications.

9. **ABB 3BHE041464R0101**: A versatile controller with advanced functionalities.

10. **ABB 07DC91**: Designed for high-speed data processing in automation tasks.

Conclusion

In conclusion, the ABB XM06B5 is a standout choice for industries seeking to enhance their automation capabilities. With its high performance, versatile communication options, and robust design, this model is tailored to meet the demands of modern industrial environments. Whether you’re involved in manufacturing, energy management, or building automation, the ABB XM06B5 provides unparalleled efficiency and adaptability. Explore the potential of ABB automation products and elevate your operations with the innovative capabilities of the ABB XM06B5.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923