K-WANG

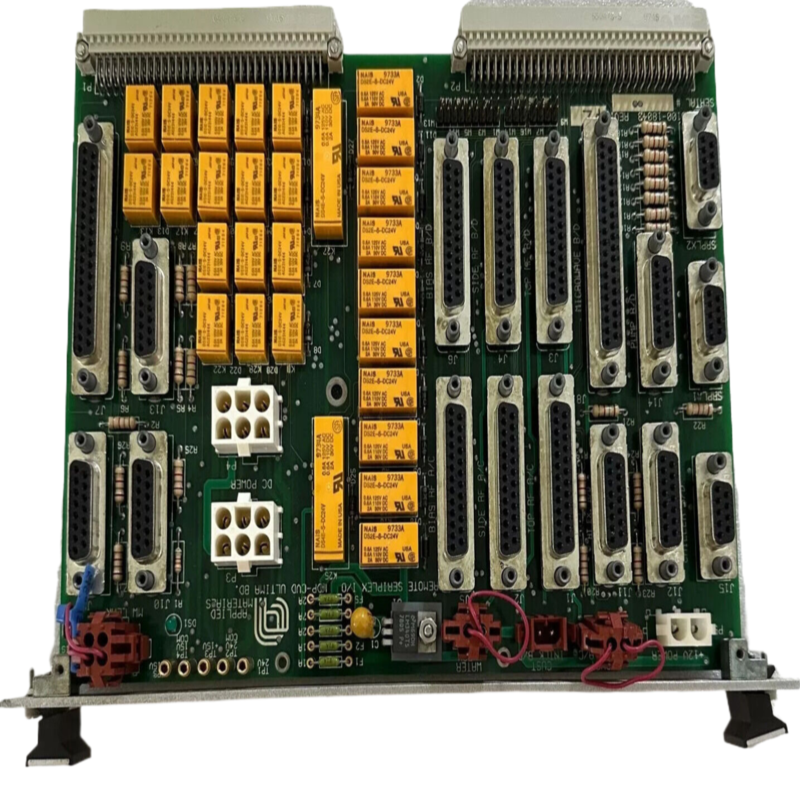

Applied Materials 0041-26333 - GAS DISTRIBUTION, 300MM ALD TIN / AMAT

The Applied Materials 0041-26333 is a highly specialized automation component designed to deliver exceptional reliability and performance in demanding industrial environments, particularly within the power industry, petrochemical sectors, and general automation applications. Engineered with precision, this model offers robust input/output capacity, advanced durability, and superior operational efficiency, making it a cornerstone product in the Applied Materials automation product lineup.

At the core of the Applied Materials 0041-26333 is its optimized input/output system, which supports high-frequency signal processing with minimal latency. The unit handles complex data streams efficiently, enabling seamless communication between various process control elements. This capability is essential in power generation plants and petrochemical facilities where real-time monitoring and rapid response to system variables are critical. The device supports a wide voltage input range and offers multiple configurable output channels, ensuring compatibility with diverse industrial control systems. Its rugged construction guarantees long service life even under harsh environmental conditions, including exposure to high temperatures, corrosive chemicals, or mechanical vibrations commonly encountered in petrochemical plants.

Performance metrics of the Applied Materials 0041-26333 highlight its ability to maintain stable operation over extended periods, with a mean time between failures (MTBF) significantly exceeding industry averages. The unit’s internal diagnostics and fault-tolerant design reduce downtime and maintenance costs, making it an invaluable asset in continuous process industries. Its compact footprint also facilitates integration into existing automation frameworks without requiring extensive modifications, a benefit that streamlines upgrades and expansions in power and automation facilities.

In real-world scenarios, the Applied Materials 0041-26333 excels in applications such as automated control of power grid substations, where precise input/output management is crucial for maintaining system stability. In petrochemical refineries, it enables fine-tuned process adjustments by accurately interfacing with sensors and actuators controlling temperature, pressure, and flow rates. For general automation, this model stands out by delivering reliable performance in assembly line robotics and automated material handling systems, where timing and synchronization are paramount.

When compared to related models within the Applied Materials portfolio, the 0041-26333 offers a unique balance of versatility and robustness. For instance, while the Applied Materials 0040-39042 and 0040-18208 provide solid I/O management solutions, they lack the extended environmental resilience and higher throughput capacity featured in the 0041-26333. Similarly, the Applied Materials 0200-02812 and 0200-36424 are designed for high-speed data processing but do not match the 0041-26333’s durability in corrosive or high-temperature settings. The Applied Materials 0010-75509 and 0010-37866W models serve complementary roles in signal conditioning but do not encompass the wide input voltage range or fault tolerance present in the 0041-26333.

Alongside the Applied Materials 0041-26333, we also offer the Applied Materials 0195-07416, Applied Materials 0020-24914, and Applied Materials 0190-07842 for ancillary control and monitoring functions that enhance overall system capability. The Applied Materials DCG-200Z OPTIMA provides advanced graphical interface options compatible with the 0041-26333 for intuitive operator control. Furthermore, the Applied Materials sm-745 and Applied Materials OEMNMCB3 expand the automation ecosystem by supporting specialized communication protocols, ensuring seamless integration within large-scale industrial automation networks. Lastly, the Applied Materials 0200-35223 and Applied Materials 0010-14216 contribute additional processing power and input/output flexibility, rounding out a comprehensive automation solution when paired with the 0041-26333.

The application of 0041-26333 in the power industry, petrochemical, and general automation sectors underscores its role as a reliable and efficient automation product. Its advanced technical features and rugged design make it particularly suited for environments where operational continuity and precision control are non-negotiable. Whether managing critical safety systems in a refinery or supporting load balancing in power distribution, the 0041-26333 delivers consistent, high-quality performance.

In summary, the Applied Materials 0041-26333 stands as a flagship automation component within Applied Materials’ extensive product range. It combines superior input/output capacity, resilience, and fault tolerance to meet the rigorous demands of the power industry, petrochemical processing, and general automation. When integrated with related models such as the Applied Materials 0040-39042, 0200-02812, 0195-07416, and DCG-200Z OPTIMA, it forms the backbone of an advanced, reliable automation infrastructure. For organizations seeking proven automation products that enhance operational efficiency and reduce downtime, the Applied Materials 0041-26333 represents a compelling choice.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923