K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

Advant Controller 31 Basic Unit

Estimated Shipping Size

Dimensions: 6.0" x 4.0" x 10.0"

(15.2 cm x 10.2 cm x 25.4 cm)

Weight: 1 lbs 8.0 oz (0.7kg )

Tariff Code: 8537109060

Country of Origin: Germany

Ships from Webster NY, USA

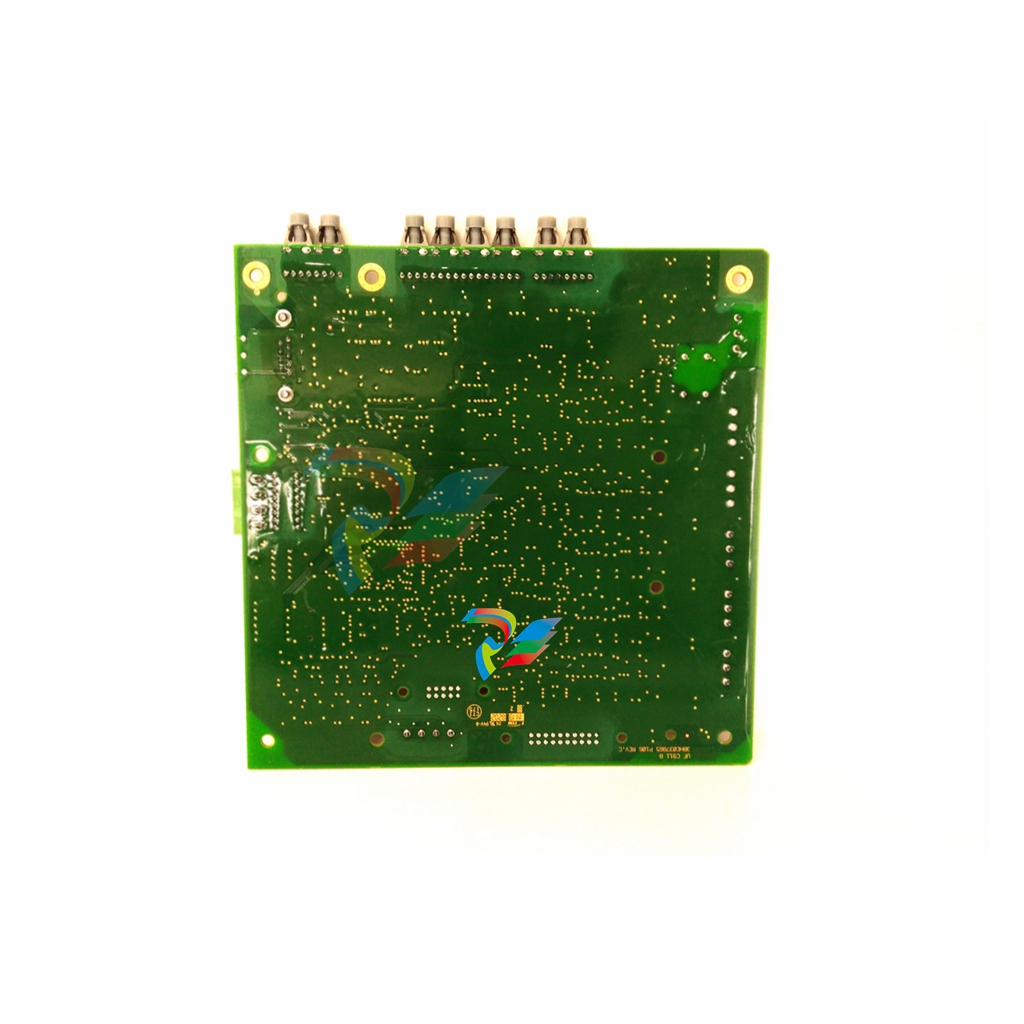

ABB GJR5250000R0353 07KR91 Advant Controller 31 Basic Unit

Basic Information

Model number and identification: ABB GJR5250000R0353 07KR91 is the model number of the Advant Controller 31 Basic Unit. This numbering system helps to accurately identify the specific configuration and functional characteristics of the product, the Advant Controller 31 Basic Unit is a core component in ABB's product portfolio for industrial automation control systems.

Origin: Usually from Sweden, where ABB has state-of-the-art production facilities with quality control and manufacturing processes that guarantee the high quality and performance of the controller.

Appearance and dimensions: The exact dimensions may vary depending on the product design and application scenario, but will generally be designed to fit into an industrial control cabinet. Its appearance is usually a compact modular structure for easy installation and maintenance in limited space.

Functional Features

Powerful control functions

Multi-tasking capability: capable of handling multiple control tasks at the same time, e.g. in a complex industrial automation production line, it can simultaneously control the movements of robots, the speed of conveyor belts, and the operating parameters of processing equipment. Through the built-in high-performance processor, it can quickly execute complex control algorithms to ensure the efficient operation of the system.

Logic control and arithmetic: It supports various logic control functions, such as logical arithmetic operations of and, or, and non-, as well as timer and counter functions. These functions make it possible to write flexible and diverse control programmes according to different industrial scenarios. For example, in a material sorting system, a timer can be used to control the time interval of the sorting action, and a counter can be used to count the number of materials sorted.

Excellent Communication Capability

Multiple Communication Interfaces: Equipped with a variety of communication interfaces, including but not limited to Ethernet interfaces, serial ports (e.g. RS-485, RS-232), etc. The Ethernet interface can be used to achieve high speed. The Ethernet interface can be used to achieve high-speed network connection, which is convenient to communicate with the host computer system, other controllers or remote monitoring centre, and the transmission speed can reach 10Mbps/100Mbps or even higher. Serial interface can be used to connect some traditional devices or play a role in close communication, and its communication rate can be set flexibly according to specific needs.

Communication protocol support: It supports a variety of industrial communication protocols, such as Profibus - DP, Modbus, CANopen, etc. These protocols make it possible to communicate with different manufacturers. These protocols make it possible to communicate with equipment from different manufacturers, realising the openness and interoperability of the system. For example, through the Profibus - DP protocol, it can carry out high-speed data exchange with ABB's I/O modules, drives and other devices, effectively transmitting control instructions and status information.

Programme storage and execution

Mass storage: Internal memory with a certain capacity is used to store control programmes, parameter settings, data records and other information. The storage capacity is generally able to meet the needs of complex industrial control programmes, for example, thousands of lines of control code and a large number of equipment parameters can be stored. This allows users to write complex automation control strategies and store them in the controller for easy recall and execution.

Efficient programme execution: It has high efficiency and stability when executing programmes. It can quickly parse and execute the instructions in the control programme to ensure the real-time response performance of the system. For example, for an emergency stop procedure that requires a quick response, the controller can execute the corresponding instructions in a very short time (usually in milliseconds) to protect the safety of equipment and personnel.

Technical Parameters

Processor performance

Processing speed: processor speed to meet the real-time requirements of industrial control, although the specific processing speed indicators may vary depending on the product configuration, but generally able to quickly handle complex control logic and a large number of data operations. For example, its instruction execution cycle may be in the nanoseconds to microseconds level, to ensure that the high load of control tasks can also be a fast response.

Word length and data processing capability: The word length of a processor determines the precision and range of data it can process. Usually, it has enough word length to handle various industrial control data, such as 32-bit or 64-bit data processing capability, which can accurately perform floating-point arithmetic, integer arithmetic, etc. to satisfy the data processing requirements in the control process.

Storage Parameters

Programme storage capacity: The internal programme memory capacity is generally between several MB and tens of MB, depending on the model and configuration. This capacity can store a large number of control programs, including main programs, subroutines, interrupt programs and so on. For example, a medium-sized automated production line control programme may take up several MB of storage space.

Data storage capacity: In addition to programme storage, it also has a certain data storage capacity for storing information such as equipment parameters, operation data, fault records, etc. The data storage capacity can also reach several MB. The data storage capacity can also reach several MB, which is convenient for users to record and analyse the long-term operation data of the equipment.

Communication parameters

Ethernet interface characteristics: The Ethernet interface supports standard network protocols such as TCP/IP, UDP, etc. The communication rate can be adjusted according to the network environment and the operating conditions. The communication rate can be adjusted according to the network environment and device configuration, and can reach up to 1000Mbps (1Gbps). At the same time, it has a certain stability of network connection and supports network redundancy, for example, it can realise the backup of network link through dual Ethernet interfaces to improve the reliability of communication.

Serial Port Characteristics: The communication rate of the serial port (e.g. RS-485) can be set flexibly between 9600bps - 115200bps, depending on the connected devices and communication requirements. Its communication distance is relatively long, in the appropriate baud rate and wiring conditions, RS - 485 interface communication distance can reach thousands of metres, to meet the requirements of long-distance communication in the industrial field.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|