K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

24 DI, 16 DO

Estimated Shipping Size

Dimensions: 6.0" x 4.0" x 10.0"

(15.2 cm x 10.2 cm x 25.4 cm)

Weight: 1 lbs 12.0 oz (0.8kg )

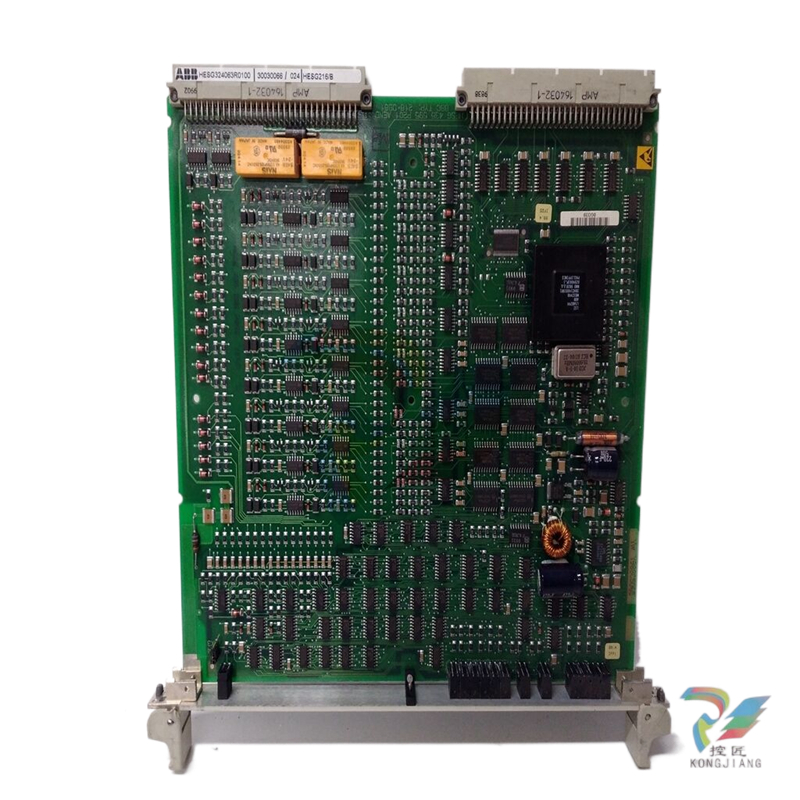

ABB GJR5252900R0200 07KT96 Control Unit

Basic information

Model number: a combination of letters and numbers, where ‘GJR5252900R0200’ is the specific model number of the control unit, used to accurately distinguish between different configurations and functions of the product; ‘07KT96’ may represent the series to which the product belongs or has specific technical specifications or application scenarios. ‘07KT96’ may represent the series to which the product belongs or have specific technical specifications, application scenarios and other information.

Functional characteristics

As a control unit, it plays a central role in industrial automation systems and is responsible for the precise control and coordination of various devices and processes. For example, it can receive signals from sensors and issue control commands to motors, valves, pumps and other actuators according to preset procedures and logic, thus realising precise regulation of physical quantities such as temperature, pressure and flow.

With a high degree of reliability and stability, able to operate stably for a long time in harsh industrial environments to ensure the continuity and reliability of the production process.

Strong compatibility and expandability, can be seamlessly integrated with other ABB automation products, such as input and output modules, communication modules, etc., to facilitate users to build a flexible and diverse automation control system according to the actual needs.

Application Fields

Power industry: used in power plants, substations and other places of equipment control and monitoring, such as the start-stop control of generating units, power grid scheduling and monitoring, to ensure the stable operation of the power system.

Chemical industry: In the process of chemical production, the temperature, pressure, material flow and other parameters of various chemical reactors are accurately controlled to ensure the safety and stability of chemical reactions and improve product quality and production efficiency.

Manufacturing industry: Widely used in automotive manufacturing, machinery processing, food and beverage production and other types of manufacturing enterprises in the automated production line, to achieve automated control of production equipment and production process optimisation and management, improve production flexibility and competitiveness.

Oil and gas industry: in the oil extraction, refining, transmission and other links, the relevant equipment and process control and monitoring, to ensure the safe and efficient operation of the production process.

Electrical interfaces

The electrical interfaces for the output of measured values and communication with external systems include

• The integrated Ethernet-10/100BASE-T interface for

– gas analyzer configuration with configuration software ECT

– QAL3 data transfer if the QAL3 monitoring option is integrated in the gas analyzer

– data transmission with Modbus TCP/IP protocol (measured values, status signals and control signals) as well as the integrated I/O modules depending on the functional range and order

· Profibus module with one RS485 and one MBP interface (also according to VDI 4201 Part 2),

· Modbus module with one RS485 and one RS232 interface (also according to VDI 4201 Part 3),

· Digital I/O module with four digital inputs and four digital outputs,

· 2-way analog output module with two analog outputs,

· 4-way analog output module with four analog outputs.

The following analyzers are available for selection:

• Uras26 infrared photometer for the measurement of infrared-active gas components, e.g. CO, NO, SO2

• Limas23 ultraviolet photometer for the measurement of NO, NO2 and SO2

• Magnos206 oxygen analyzer for the measurement of O2 in process gas or in N2

• Magnos28 oxygen analyzer for the measurement of O2 in process gas or in N2

• Magnos27 oxygen analyzer for the measurement of O2 in flue gas or in N2

• ZO23 trace oxygen analyzer for the measurement of O2 in pure gases (N2, CO2, Ar)

• Caldos27 thermal conductivity analyzer for the measurement of binary gas mixtures with different thermal conductivity, e.g. Ar in O2, H2 in Ar, CH4 in N2

• Fidas24 flame-ionization detector for the measurement of hydrocarbons

• Electrochemical oxygen sensor for the measurement of O2

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923