K-WANG

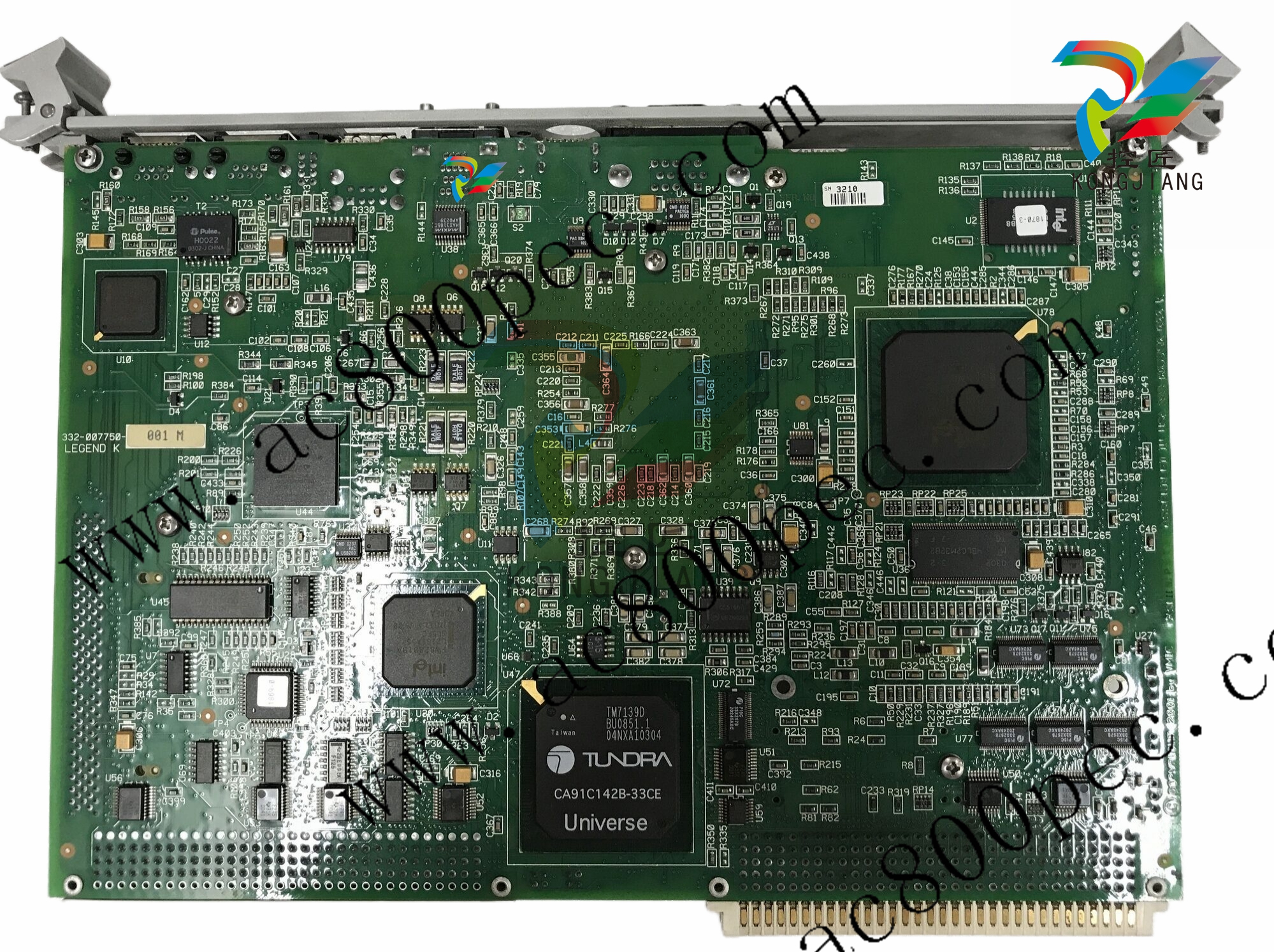

Honeywell CD815 - Control Display Unit 7022360-902 Removed Working

The Honeywell CD815 stands out as a robust and versatile automation controller designed to meet the demanding requirements of the power industry, petrochemical plants, and general automation applications. Engineered to deliver exceptional reliability and performance, the CD815 offers a powerful combination of input/output capacity, durability, and processing speed, making it a preferred choice for critical industrial control tasks.

At its core, the Honeywell CD815 features a modular architecture that supports extensive I/O configurations, enabling seamless integration with a wide array of sensors, actuators, and field devices. The controller supports both analog and digital input/output channels, with high-resolution data acquisition capabilities that ensure precision monitoring and control. With an input capacity designed to handle hundreds of signals simultaneously, the CD815 excels in complex automation environments where real-time data processing and rapid response times are essential.

Durability is a hallmark of the CD815, as it is built to withstand harsh industrial conditions. Its rugged construction resists extreme temperatures, vibrations, and electrical noise commonly encountered in power plants and petrochemical facilities. This resilience guarantees continuous operation with minimal downtime, a critical factor in industries where operational interruptions can lead to significant financial losses or safety hazards. Additionally, the CD815 supports redundant power supplies and communication channels, further enhancing its reliability and fault tolerance.

Performance-wise, the Honeywell CD815 boasts a high-speed processor optimized for real-time control algorithms and data analytics. The controller facilitates advanced process automation strategies, including PID control, sequence logic, and interlocking, which are vital for maintaining optimal operational efficiency and safety compliance in industrial settings. Its compatibility with Honeywell’s Experion® Process Knowledge System (PKS) and other supervisory control and data acquisition (SCADA) platforms ensures smooth integration into existing control infrastructures.

In practical applications, the Honeywell CD815 excels in the power industry by managing complex power generation and distribution processes, ensuring stable grid operations, and enabling predictive maintenance through precise monitoring. In the petrochemical sector, its robust control capabilities support hazardous environment operations, helping maintain product quality and safety through stringent process control. For general automation, the CD815’s flexibility allows it to adapt to diverse manufacturing and processing systems, streamlining operations and improving overall productivity.

When comparing the Honeywell CD815 to other Honeywell automation products, its unique advantage lies in its balanced combination of high input/output capacity, ruggedness, and advanced processing power. For example, while the Honeywell UDC3200 excels in temperature control applications and the Honeywell RM7840E1016 offers specialized relay functions, the CD815 provides a more comprehensive platform for integrated process control across multiple variables. Similarly, compared to the Honeywell MC-TAMR03 and MC-TAMR04 modules, which serve as specialized I/O expansions, the CD815 offers a broader standalone solution with greater scalability.

Alongside the Honeywell CD815, Honeywell offers complementary models such as the Honeywell SMV800 for control valve management, the Honeywell HH82AZ-209 for sensor integration, and the Honeywell 2108B2101N for safety instrumented systems. The Honeywell IVA81D and Honeywell 1153304-2 modules enhance communication and interface capabilities, ensuring seamless connectivity across diverse automation networks. For environments requiring precise measurement and control, the Honeywell Q7055C1009/U and Honeywell DC2501-0E-0000-100-00000-EC-0 sensors provide reliable data inputs that can be effectively processed by the CD815 controller.

The application of the Honeywell CD815 in power industry, petrochemical, and general automation settings underscores its versatility and efficiency. Its integration capabilities with other Honeywell products such as the Honeywell 51401583-200 and Honeywell 1604-500 sensors further expand its functionality, making it an essential component in complex automation ecosystems. Whether deployed in a power generation facility, a chemical processing plant, or a diverse manufacturing line, the CD815 guarantees consistent performance and operational excellence.

In summary, the Honeywell CD815 combines rugged durability, high input/output capacity, and advanced processing power tailored for industrial automation demands. Its adaptability to harsh environments and integration with a wide range of Honeywell automation products make it an indispensable asset in the power industry, petrochemical sector, and general automation fields. By choosing the Honeywell CD815, industries benefit from enhanced control precision, operational reliability, and scalable automation solutions that align with modern industrial standards and future growth requirements.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923