K-WANG

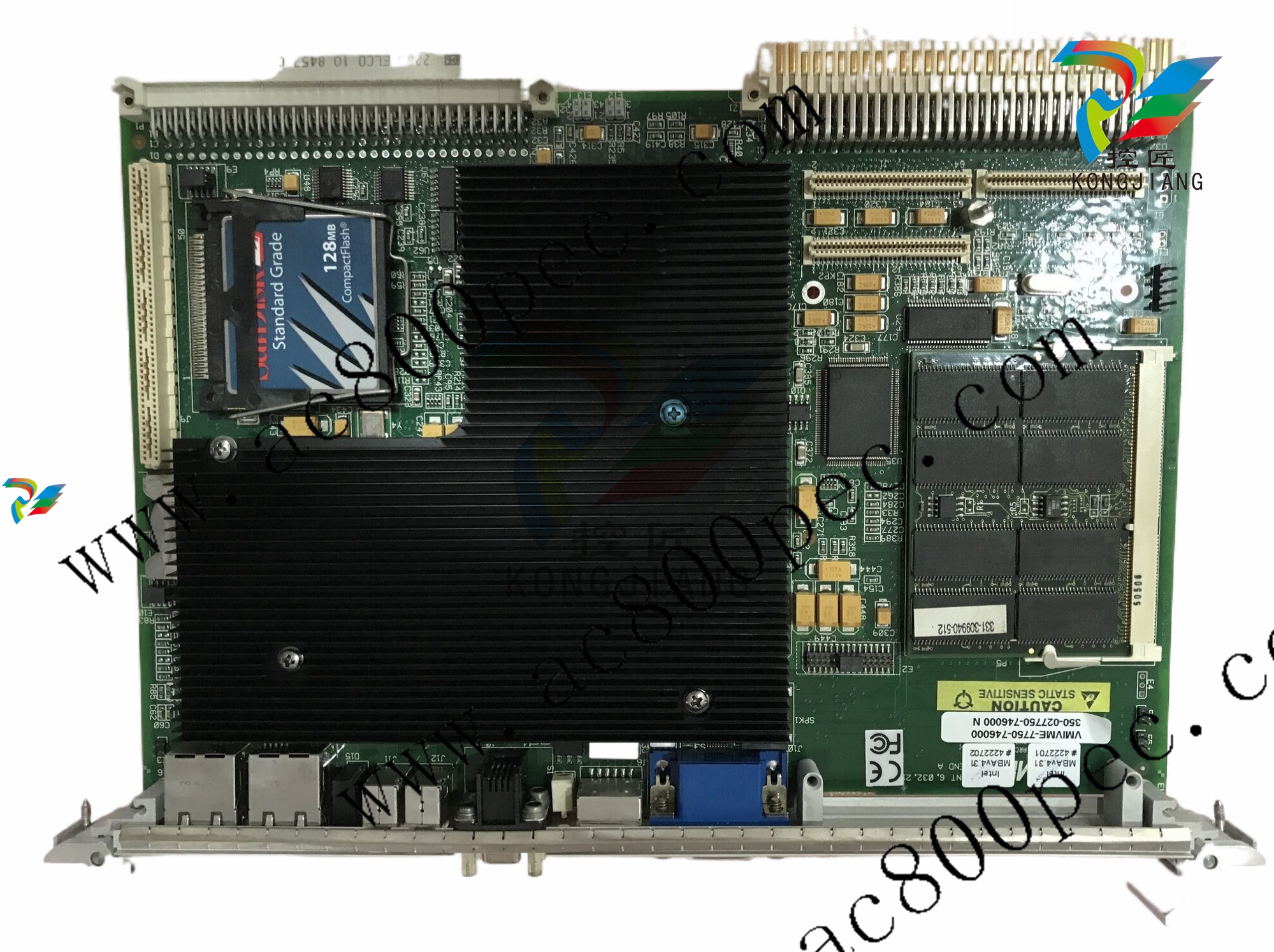

Honeywell K4LCN - 51402755-100 Motherboard SS 51201795-400

The Honeywell K4LCN is a robust and highly reliable controller designed to meet the demanding requirements of the power industry, petrochemical plants, and general automation environments. Engineered with precision, the K4LCN stands out for its exceptional input/output capacity, rugged durability, and superior performance metrics that ensure consistent operation even under the harshest industrial conditions.

At its core, the Honeywell K4LCN offers extensive I/O flexibility, supporting a wide range of analog and digital inputs and outputs. This capability allows seamless integration with various sensors, actuators, and field devices, critical for real-time monitoring and control applications. The controller’s high-speed processing unit delivers rapid data acquisition and execution of control algorithms, enabling precise regulation of processes. Built with industrial-grade components, the K4LCN exhibits exceptional resistance to temperature fluctuations, vibration, and electromagnetic interference, ensuring longevity and minimal downtime in challenging environments.

In practical terms, the Honeywell K4LCN excels in applications such as power generation control systems, where it manages turbine speed, load distribution, and safety interlocks with high accuracy. In petrochemical plants, it facilitates complex process control for reactors, distillation columns, and heat exchangers, optimizing throughput while maintaining safety standards. The controller’s versatility also extends to general automation tasks, including assembly line coordination, material handling, and environmental monitoring, proving its adaptability across diverse industrial sectors.

Compared to other Honeywell automation products, the K4LCN delivers unique advantages in scalability and ruggedness. For instance, while models like the Honeywell UDC3200 and Honeywell DC3200-EE-000R-240-00000-E0-0 offer excellent temperature and process control capabilities, the K4LCN’s broader I/O range and enhanced processing speed make it more suitable for complex multi-variable systems requiring rapid response times. Similarly, though the Honeywell RNZ850 and Honeywell 7000605-902 are reliable controllers, they often serve more specialized or limited I/O configurations, whereas the K4LCN is engineered for versatile, large-scale automation frameworks.

Alongside the Honeywell K4LCN, the Honeywell 30755888-501 and Honeywell 51301877-100 provide complementary sensor and actuator modules, enhancing overall system integration. The Honeywell NXS0500A1009 and Honeywell 2586689-902 are excellent peripheral devices for signal conditioning and communication, further expanding the K4LCN’s connectivity options. For advanced process control, the Honeywell DPR500 and Honeywell PGM-7360 offer specialized functionalities that can be integrated with the K4LCN for optimized performance in petrochemical and power industry setups. Additionally, the Honeywell 51304190-200 and Honeywell 51107403-100 serve as effective monitoring and diagnostic tools, enabling predictive maintenance and minimizing operational disruptions.

The application of K4LCN in power industry, petrochemical, and general automation is supported by its compliance with rigorous industry standards, including IEC and ANSI certifications, ensuring safety and interoperability. Its programmable logic capabilities allow customization to specific process requirements, while onboard data logging and remote access facilitate comprehensive monitoring and control from centralized operation centers.

In summary, the Honeywell K4LCN is a cornerstone product within the Honeywell automation products portfolio, combining high performance, durability, and versatility. Its robust input/output architecture and fast processing ensure it meets the complex control demands of power plants, petrochemical facilities, and automated manufacturing lines. When integrated with other Honeywell models such as the UDC3200, RNZ850, DPR500, and 30755888-501, it forms a cohesive and scalable automation solution tailored to modern industrial challenges, making it an indispensable asset for engineers and plant operators alike.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923