K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

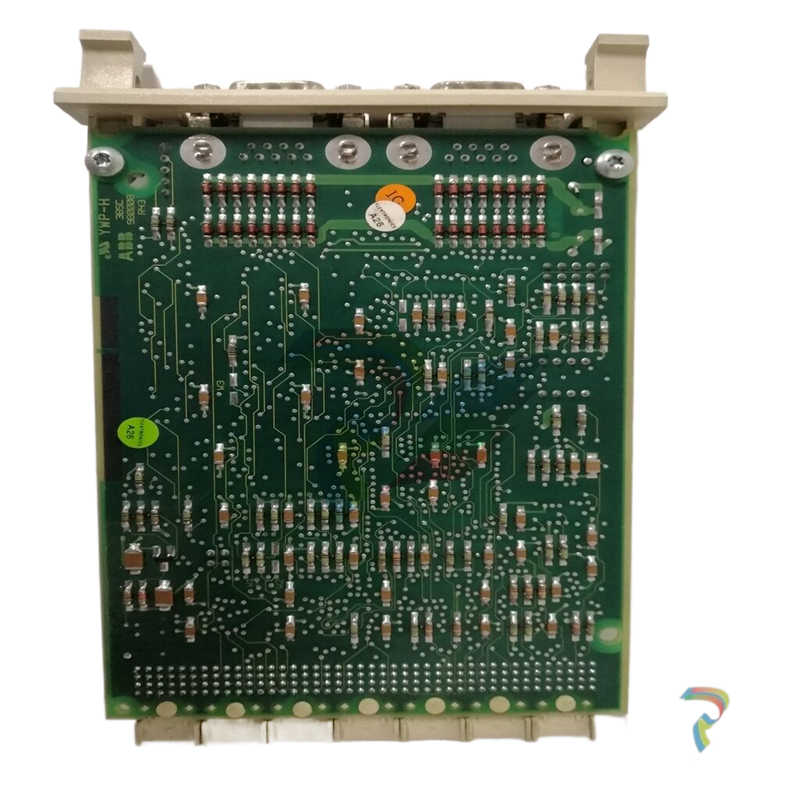

ABB P-HC-DOC-22011000 Applications Platform Docking Station - HAC

Functionality

Device connection and expansion: The docking station is equipped with various types of interfaces, such as Ethernet interface, serial interface, etc., which can conveniently connect all kinds of external devices, such as sensors, actuators, field instruments, etc., and realise the close connection between the HAC system and the field devices, and effectively expand the input and output capacity of the system.

Data Communication and Processing: Supporting high-speed and stable data transmission, it can be used as the hub of data communication to accurately and precisely transmit the data from the connected devices to the HAC system, and carry out the necessary pre-processing and conversion of the data to ensure the consistency and compatibility of the data, and improve the overall communication efficiency of the system.

System integration and synergy: Highly integrated with the HAC system, the docking station can work seamlessly with other components in the system to complete complex control tasks. Through the docking station, it is possible to realise the synergy between multiple devices, which enhances the coordination and reliability of the whole system.

Technical Parameters

Communication protocol support: support for a variety of common industrial communication protocols, such as Profibus, Modbus, Ethernet/IP, etc., can be flexibly configured according to the actual application requirements, to meet the communication requirements between different devices.

Data transmission rate: with high data transmission rate, it can meet the data transmission needs of industrial sites with high real-time requirements, and the specific transmission rate may vary according to the different configurations and communication protocols.

Interface type and number: usually include multiple Ethernet interfaces (RJ45), serial interfaces (RS-232, RS-485), etc. The number and type of different interfaces can be customised according to specific models and application scenarios.

Hardware Design

Rugged and durable shell: made of high-quality engineering plastics or metal, with good impact resistance, dustproof and waterproof, can adapt to harsh industrial environments, to ensure the stability and reliability of the equipment in the process of long-term operation.

Reasonable interface layout: the interface layout is carefully designed to facilitate users to connect and wire the equipment. Each interface is clearly labelled for easy identification and operation, reducing the risk of failure due to incorrect interface connections.

Reliable power management: The built-in power management module is able to provide stable and reliable power supply for the connected devices, and is equipped with functions such as over-voltage, over-current, and short-circuit protection, which effectively protects the devices from power supply fluctuations and improves the safety of the system.

Application Areas

Industrial automation production line: in automobile manufacturing, electronic manufacturing, food and beverage processing and other types of industrial automation production line, can be used to connect production equipment, testing equipment, robots, etc., to achieve automated control and monitoring of the production process, improve production efficiency and product quality.

Energy management system: In the field of electricity, oil, natural gas and other energy, it can be used as an important part of the energy management system, connecting energy metering equipment, monitoring equipment, etc., to achieve real-time monitoring and analysis of energy consumption, and provide data support for energy saving and emission reduction.

Intelligent building and facility management: In intelligent buildings, it can be used to connect air-conditioning systems, lighting systems, security systems and other equipment to achieve intelligent management and control of the building, and improve energy efficiency and comfort.

Our Main Brands

· - ABB Advant-800xA,Advant OCS,Bailey Infi 90 and Net 90,H&B Freelance 2000,DSQC Robots,IGCT / IGBT

· - GE General Electric Field Control, Genius I/O, QuickPanel, RX3i PacSystem, Series 90, Series 90, Series VersaMax

· - Allen Bradley Allen-Bradley SLC500, MicroLogix, CompactLogix, ControlLogix, PLC-5, Panel View,

· - Bently Nevada 3300 System, 3500 System

· - Honeywell 7800 Series, FSC, IPC, Mxopen, TDC 2000, TDC 3000, Experion PKS(C200,C300)

· - Yokogawa Centum CS - Centum VP, Centum XL - micro XL, FA-M3, ProSafe-PLC

· - Ovation, Foxboro, EPRO, Emerson DeltaV, Fuji, Siemens, HIMA, Prosoft, Invensys Triconex, ICS TRIPLEX, Woodward, Bachmann, Schneider

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923