K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

ABB H&B Contronic XI 01 module XI 01 H&B Contronic

Basic Information

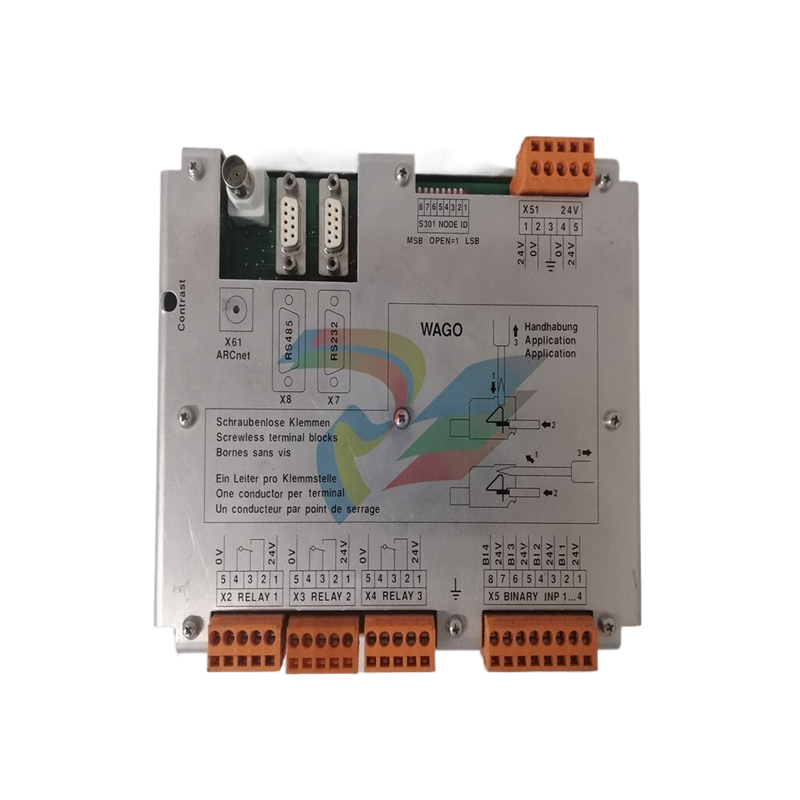

Model: The specific model is XI 01, usually with standard industrial module shell, the colour is usually industrial grey or black, the shell material has good anti-corrosion, anti-static and dustproof performance to adapt to the harsh environment of the industrial site.

Appearance and size: generally rectangular shape, compact size, the specific size of the exact public data is not available, moderate weight, easy to install and dismantle in the control cabinet or other industrial equipment.

Technical Parameters

Power supply requirements: usually 24V DC or so DC voltage supply, the voltage allows a certain range of fluctuations, in order to adapt to the unstable power supply voltage in the industrial field.

Input and output channels: It has multiple digital and analogue input and output channels, which can be flexibly configured and expanded to meet the needs of different industrial control scenarios. The digital input channel has high anti-interference ability and can accurately receive and process digital signals from sensors, switches and other devices; the analogue input channel can receive and process continuously changing analogue signals, such as those from sensors for temperature, pressure, flow and so on.

Communication interface: It supports various communication protocols such as Profibus, Modbus, industrial Ethernet, etc. It can be conveniently networked and communicated with other devices to realise real-time transmission and sharing of data, and it is convenient to be used as a node in the industrial automation network to exchange data and work together with other devices.

Functional features

Precise control function: It can achieve precise control of various equipments and processes in the industrial production process, such as starting and stopping of motors, speed adjustment, opening control of valves, adjustment of temperature, pressure and other parameters, etc. Through internal control logic and algorithms, it analyses and processes the input signals and outputs corresponding control signals in order to achieve automated production and process control.

Comprehensive diagnosis and monitoring: Built-in diagnostic function can monitor its own working status and operating parameters in real time, such as power supply voltage, working temperature, communication status, etc., and can send this information to the host computer or other monitoring equipment through the communication interface, and when there is a malfunction or anomalies, it can send out an alarm signal in time, which is convenient for the maintenance personnel to locate and remove the malfunctions quickly.

FEATURES

• Process Station with integrated fieldbus capability

• 4 high-speed fieldbus lines

• Supports different fieldbus types, even simultaneously: PROFIBUS-DP, up to 12 MBd Modbus CAN Foundation Fieldbus H1 (with LD800 HSE)

• Easy engineering: fully integrated in Control Builder F

• One unified database for field devices shared by the control level and the Human System Interface (HSI)

• Module recognition with factory and operational parameters

• Comprehensive diagnostics for proactive maintenance

• Compact, rugged design

• Front panel connectors

• DIN Rail (C-rail) or wall mounting for easy installation

• Ambient temperature 0-60 °C (32-140 °F) with temperature monitoring

• EMC certification according to EN50082

• Certification: CE, NAMUR, CSA, UL, EN61000-6-2.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923